- Part 1. Introduction

- Part 2. The science behind battery monitor shunts

- Part 3. Types of battery monitor shunts and their applications

- Part 4. Measuring battery current with shunt resistors

- Part 5. Installation best practices for battery monitor shunts

- Part 6. Advanced applications and smart monitoring systems

- Part 7. Challenges and future innovations

- Part 8. Conclusion

Part 1. Introduction

As energy systems become more sophisticated, the need for accurate battery monitoring has never been greater. Whether in renewable energy systems, electric vehicles (EVs), industrial power backup, or marine applications, ensuring precise measurement of battery charge and discharge is critical for optimizing performance and longevity.

A battery monitor shunt is a fundamental component in battery management systems (BMS), enabling real-time current measurement with high precision and minimal energy loss. However, beyond the basics, there are multiple considerations, including shunt calibration, measurement accuracy, thermal stability, and integration with smart energy platforms.

This guide delves into the working principles of shunts, their role in advanced battery management, and how modern AI-driven systems are revolutionizing energy monitoring.

Part 2. The science behind battery monitor shunts

What Is a Battery Monitor Shunt?

A shunt resistor is a low-resistance precision component designed to measure high current flow by detecting voltage drop across its terminals.

The fundamental principle relies on Ohm’s Law (V = IR), where:

- V is the measured voltage drop,

- I is the battery current,

- R is the known resistance of the shunt.

Since the resistance of a shunt is typically in the micro-ohm (µΩ) range, even large currents produce only minimal voltage drops, ensuring negligible power dissipation while maintaining accuracy.

Key Electrical Parameters of a Battery Monitor Shunt

1. Resistance (Rshunt):

-

Measured in milliohms (mΩ) or micro-ohms (µΩ).

-

Must be carefully selected to minimize energy loss while maintaining sufficient voltage drop for accurate measurement.

-

Example: A 500A / 50mV shunt has a resistance of 0.1 mΩ (50mV / 500A).

2. Voltage Drop (Vshunt):

-

Typical values: 50mV, 75mV, or 100mV.

-

Lower voltage drops reduce energy loss but require high-precision measurement circuits.

3. Power Dissipation (Pshunt):

-

Given by P = I²R, where power loss should remain minimal.

-

Example: A 500A shunt with 50mV drop dissipates 25W (500² × 0.0001Ω).

Part 3. Types of battery monitor shunts and their applications

1. Standard Precision Shunts

-

Used in solar energy systems, RVs, and boats.

-

Provides a stable voltage drop proportional to current flow.

2. Temperature-Compensated Shunts

-

Used in high-current industrial applications where thermal drift can impact accuracy.

-

Equipped with temperature compensation circuits to correct resistance variation.

3. Smart Digital Shunts

-

Integrated with microcontrollers and wireless communication.

-

Found in high-end EVs, IoT-enabled power monitoring, and AI-driven battery management systems.

Part 4. Measuring battery current with shunt resistors

1. Direct Measurement Circuit

-

The simplest method where a high-precision voltmeter or ADC (Analog-to-Digital Converter) directly measures the shunt voltage drop.

-

Used in basic battery monitors and off-grid solar controllers.

2. Differential Amplifier-Based Measurement

-

Uses precision instrumentation amplifiers to isolate and amplify the shunt voltage.

-

Common in automotive and industrial power systems.

3. Hall-Effect vs. Shunt-Based Current Sensing

| Feature | Shunt Resistor | Hall-Effect Sensor |

|---|---|---|

| Accuracy | High (milliohm precision) | Moderate |

| Temperature Sensitivity | Moderate | High |

| Power Consumption | Low | High |

| Isolation | Requires direct connection | Fully isolated |

Shunt-based sensing is generally preferred for high-precision energy monitoring, while Hall-effect sensors are used in isolation-critical applications.

Part 5. Installation best practices for battery monitor shunts

1. Selecting the Correct Shunt Rating

-

Choose a shunt that matches the maximum expected current in your system.

-

Example: A 2000W solar system (12V, ~166A max current) requires a 200A shunt for headroom.

2. Proper Wiring and Connection

-

Always install the shunt in the negative (-) battery lead to avoid floating voltage issues.

-

Use short, thick cables to reduce resistance and voltage drop.

3. Noise and Signal Integrity Considerations

-

Shielded cables help prevent EMI (Electromagnetic Interference) in high-power environments.

-

Placement near high-frequency switching components (e.g., MPPT controllers, inverters) should be avoided.

Part 6. Advanced applications and smart monitoring systems

1. AI-Enhanced Battery Monitoring

-

Tesla and Rivian integrate AI-driven BMS algorithms that analyze shunt readings to optimize range and battery longevity dynamically.

-

Machine learning models predict charge/discharge efficiency losses over time.

2. Blockchain for Secure Battery Energy Tracking

-

In renewable energy microgrids, blockchain-based platforms track battery energy transactions using shunt data logs.

-

Ensures tamper-proof energy accounting in distributed power networks.

3. High-Resolution Shunts in Aerospace and Defense

-

NASA and SpaceX utilize cryogenically cooled ultra-low-resistance shunts to measure precise current flow in spacecraft power systems.

-

High-resolution current sensing enables predictive maintenance for critical power subsystems.

Part 7. Challenges and future innovations

1. Addressing Thermal Drift in High-Power Applications

New materials such as graphene-based shunts promise ultra-low thermal drift, enhancing long-term accuracy.

2. Integration with Next-Generation Battery Chemistries

Solid-state batteries require lower resistance and more sensitive monitoring systems, pushing shunt development into new frontiers.

3. AI-Driven Predictive Battery Health Analysis

AI-powered battery monitors will self-calibrate and predict failures before they occur, reducing system downtime.

Part 8. Conclusion

Battery monitor shunts are indispensable tools for accurate energy measurement, enabling efficient power management across diverse industries.

Key Takeaways:

- Choose the right shunt rating based on system current capacity.

- Use high-precision amplifiers for accurate voltage measurement.

- Integrate with AI-driven BMS for enhanced battery life and efficiency.

- Future trends include graphene-based shunts, blockchain tracking, and AI-powered diagnostics.

By understanding the fundamentals, applications, and emerging innovations in battery monitor shunt technology, we can ensure more efficient, reliable, and future-proof energy management systems.

Related Tags:

More Articles

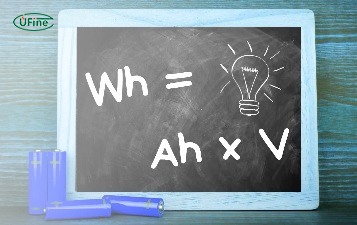

What are Watts and Watt Hours in Battery?

Understand watt vs watt-hour in batteries, how to calculate battery watt hours, and what Wh means for car batteries, devices, and energy storage.

A Complete Guide to the Best Batteries for Flashlights

Compare the best batteries for flashlights, including AA, AAA, 18650, 21700, CR123A. See which battery offers the best brightness, runtime, and reliability.

How Long Do Rechargeable AA Batteries Last?

How long do rechargeable AA batteries last? Compare NiMH and lithium AA lifespan, recharge cycles, key factors, and performance vs alkaline batteries.

How Much Current Can a 9V Battery Really Supply?

Discover how many amps a 9V battery can supply, its actual current output, discharge rate, and capacity for alkaline, lithium, and rechargeable 9V batteries.

12V STD vs 12V AGM: Meaning, Differences, and Which Is Better

Understand what STD and AGM batteries mean, their key differences, and which 12V battery fits your needs best in 2026.