- Part 1. What is a battery strap down?

- Part 2. What is a battery hold-down bracket?

- Part 3. Battery strap down vs battery hold-down bracket: Structural difference

- Part 4. Battery strap down vs battery hold-down bracket: Performance comparison

- Part 5. Battery strap down vs battery hold-down bracket: Which is better for lithium batteries?

- Part 6. Battery strap down vs battery hold-down bracket: Which is better for lead-acid batteries?

- Part 7. Battery strap down vs battery hold-down bracket: Application-based recommendations

- Part 8. Battery strap down vs battery hold-down bracket: Safety considerations

- Part 9. Battery strap down vs battery hold-down bracket: Pros and cons summary

- Part 10. Battery strap down vs battery hold-down bracket: Which one should you choose?

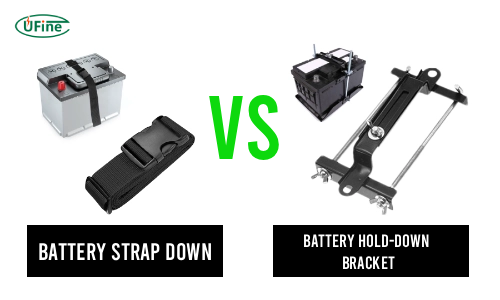

Securing a battery may appear simple, but the method used directly affects system stability, electrical safety, vibration resistance, and long-term battery lifespan. In automotive, marine, solar storage, and lithium battery applications, two mounting solutions dominate: the battery strap down and the battery hold-down bracket.

Both serve the same primary purpose—prevent battery movement—but the similarities end there. Each system has different materials, structural characteristics, safety functions, installation requirements, and ideal use cases. Choosing the wrong one can lead to premature case wear, excessive vibration, terminal stress, electrical instability, or even system failure.

This in-depth guide explores the differences in design, function, performance, and compatibility to help users select the correct securing system for lithium, LiFePO4, lead-acid, and deep-cycle batteries.

Part 1. What is a battery strap down?

A battery strap down is a flexible securing mechanism designed to hold a battery in place using tension rather than rigid compression. A strap down wraps around the battery or battery box and tightens using Velcro, a cam buckle, a ratchet buckle, or a locking clasp.

1 Common Materials

Battery strap downs are typically made from:

- Nylon webbing — durable and cost-effective

- Polyester fiber — high tensile strength and abrasion resistance

- Polypropylene — lightweight and moisture-resistant

- Marine-grade straps — UV-resistant for outdoor environments

- Hook-and-loop (Velcro) straps — adjustable and easy to use

- Elastic composite straps — provide shock absorption

These materials enable controlled flexibility, which helps mitigate vibration and impact forces.

2 Key Functional Features

- Adjustable tension

- Conforms to the battery’s shape

- Lightweight and compact

- Easy tool-free installation

- Excellent vibration absorption

- Compatible with different battery sizes

- Suitable for battery boxes and battery trays

3 Typical Applications

Battery strap downs are widely used in applications where vibration and weight matter:

- RV, camping, and caravan LiFePO₄ systems

- Marine deep-cycle and trolling motor batteries

- Portable power stations

- Small EVs and mobility equipment

- Robotics and drones

- Power sports (ATVs, UTVs, motorcycles)

- Lightweight solar and off-grid systems

The flexibility and vibration-absorbing nature of strap downs make them especially popular for lithium batteries, which are more sensitive to compression than lead-acid batteries.

Part 2. What is a battery hold-down bracket?

A battery hold-down bracket is a rigid, mechanical mounting system designed to clamp the battery securely in place. Brackets are typically installed using bolts, threaded rods, or metal bars.

1 Common Materials

Battery hold-down brackets are usually made from:

- Powder-coated steel — high strength, corrosion-resistant

- Stainless steel — excellent durability for marine environments

- Aluminum — lightweight and rust-proof

- ABS heavy-duty plastic — resistant to chemicals and vibration

- OEM composite brackets — used in automotive systems

These rigid structures physically restrain the battery and prevent movement in all directions.

2 Key Functional Features

- High mechanical rigidity

- Long-term stability

- Bolted installation for fixed mounting

- Suitable for heavy batteries

- Designed for standardized battery sizes

- Strong resistance against G-forces

3 Typical Applications

Hold-down brackets are widely used in environments where the battery remains in one position for long periods:

- Automotive starter batteries (12V lead-acid)

- Marine starting batteries

- Industrial equipment

- Forklifts and golf carts

- UPS backup battery racks

- Stationary solar storage banks

- Heavy deep-cycle lead-acid systems

When the mounting space is predefined—such as engine bays—the hold-down bracket is usually mandatory.

Part 3. Battery strap down vs battery hold-down bracket: Structural difference

The fundamental difference between the two systems lies in their mechanical behavior:

- Battery Strap Down = Flexible Restraint

- The strap conforms to the battery and applies distributed tension, reducing stress concentration.

- Battery Hold-Down Bracket = Rigid Compression

- The bracket clamps the battery using structured, fixed contact points and applies direct compressive force.

Part 4. Battery strap down vs battery hold-down bracket: Performance comparison

1 Vibration Control

Strap Down

Offers superior vibration damping due to flexible materials.

Ideal for lithium batteries and lightweight systems.

Hold-Down Bracket

Effective against large, sudden impacts but transmits more vibration to the battery.

Winner: Strap Down for vibration-sensitive applications.

2 Installation Difficulty

Strap Down

- Tool-free

- Fits multiple battery sizes

- Fast installation and removal

Hold-Down Bracket

- Requires bolts, screws, or threaded rods

- Precision alignment needed

- More labor-intensive

Winner: Strap Down

3 Weight and Space Requirements

Strap Down

- Minimal added weight

- Works in tight spaces

- Easy to store

Hold-Down Bracket

- Heavier

- Requires dedicated mounting position

- Not ideal for mobile or compact devices

Winner: Strap Down

4 Stability for Heavy Batteries

Strap Down

Stable for small to mid-size batteries

But limited for batteries above 30–40 kg.

Hold-Down Bracket

Excellent for heavy lead-acid and large bank installations.

Winner: Hold-Down Bracket

5 Compatibility With Lithium Battery Construction

Lithium batteries—especially LiFePO₄—use:

- prismatic cells

- cylindrical cells

- pouch cells

Many of these chemistries are more sensitive to compression and deformation than lead-acid.

Strap Down

Applies uniform, gentle pressure.

Better for lithium casing integrity.

Hold-Down Bracket

Can create point pressure over time.

Risk of case deformation if overtightened.

Winner: Strap Down

Part 5. Battery strap down vs battery hold-down bracket: Which is better for lithium batteries?

Lithium battery casings, BMS modules, and terminal structures generally favor non-rigid securing solutions. Excessive compression from a bracket may damage:

- the battery case

- internal cell alignment

- epoxy insulation layers

- the BMS shell

- terminals or busbars

Strap Downs Are Usually the Best Choice for Lithium

Especially for:

- LiFePO₄ RV batteries

- marine lithium packs

- solar portable units

- motorcycle lithium replacements

- robotics and mobile devices

Vibration absorption and flexibility protect internal components and offer the safest securing method in most lithium applications.

Part 6. Battery strap down vs battery hold-down bracket: Which is better for lead-acid batteries?

Lead-acid chemistries (flooded, AGM, GEL) are heavier and structurally rigid. Their thick plastic cases tolerate compression well.

Hold-Down Brackets Are the Standard for Lead-Acid

Common in:

- cars

- boats

- industrial vehicles

- starter batteries

- forklift batteries

The added weight and thicker casing favor the stability of a rigid bracket.

Part 7. Battery strap down vs battery hold-down bracket: Application-based recommendations

| Application | Best Option | Why |

|---|---|---|

| RV LiFePO₄ system | Strap down | Flexible, vibration-absorbing |

| Marine trolling motor | Strap down | Corrosion-resistant, absorbs shock |

| Automotive engine bay | Hold-down bracket | OEM requirement |

| Solar power bank | Bracket | Long-term stationary use |

| Portable battery box | Strap down | Speed + flexibility |

| Off-road power sports | Strap down | Handles vibration |

| Industrial UPS | Bracket | Heavy stationary units |

| Golf carts | Bracket | Large battery weight |

Part 8. Battery strap down vs battery hold-down bracket: Safety considerations

1 Strap Down Safety Tips

- Avoid overtightening (can deform casing)

- Choose UV-resistant straps for outdoor use

- Ensure buckle is high strength

- Check straps periodically for fraying

- Add padding for shock-intensive environments

2 Hold-Down Bracket Safety Tips

- Do not overtighten the bolts

- Use anti-corrosion coatings

- Ensure bracket matches battery group size

- Avoid direct metal-to-battery contact

- Verify torque specs for large batteries

Part 9. Battery strap down vs battery hold-down bracket: Pros and cons summary

1 Strap Downs

Pros:

- Lightweight

- Vibration-resistant

- Simple installation

- Safe for lithium batteries

- Flexible compatibility

Cons:

- Not ideal for heavy batteries

- Requires periodic tension checks

2 Hold-Down Brackets

Pros:

- Very stable for large batteries

- Long-term reliability

- Ideal for automotive and industrial use

- Resistant to high G-forces

Cons:

- More difficult installation

- Higher weight

- Can apply harmful compression to lithium packs

Part 10. Battery strap down vs battery hold-down bracket: Which one should you choose?

Both systems serve an important purpose, but they are not interchangeable.

1 Choose a strap down when:

- the battery is lithium-based (including LiFePO₄)

- the system experiences frequent vibration

- fast installation is needed

- the application is mobile, portable, or marine

- the battery size may change later

2 Choose a hold-down bracket when:

- the battery is heavy

- the mount is fixed and permanent

- the environment produces high G-forces

- the battery is lead-acid or AGM

- automotive OEM systems require it

For modern lightweight lithium systems, strap downs generally offer better protection, easier installation, and improved vibration performance.

Related Tags:

More Articles

Lithium-Ion vs Lead-Acid AMR & AGV Batteries Compared

Discover the pros and cons of lithium-ion and lead-acid AMR & AGV batteries. Learn about cost, lifespan, safety, and which is right for your fleet.

Robot Vacuum Battery Replacement: Easy Step-by-Step Guide

Learn how to replace a robot vacuum battery safely and easily. Step-by-step instructions, battery types, costs, and common mistakes to avoid.

Discover how to choose the right battery for your robot. Compare Li-ion, LiFePO₄, NiMH, and more for performance, safety, and cost.

Inside Humanoid Robot Battery Pack Design

A deep dive into humanoid robot battery pack design, covering battery life, voltage, capacity, safety, and real-world engineering trade-offs.

Humanoid Robot Battery Life: How Long Do They Really Last?

Most humanoid robots run 1.5–4 hours per charge. Learn real-world battery life, battery types, capacity limits, and future improvements.