- Key Takeaways

- Part 1. What is an NMC lithium-ion battery?

- Part 2. NMC battery chemistry: anode, cathode, and working principle

- Part 3. NMC battery specifications

- Part 4. NMC battery degradation and aging: why performance declines over time

- Part 5. NMC battery types: From 111 to 811

- Part 6. Advantages and disadvantages of NMC batteries

- Part 7. How can you extend the life of an NMC battery?

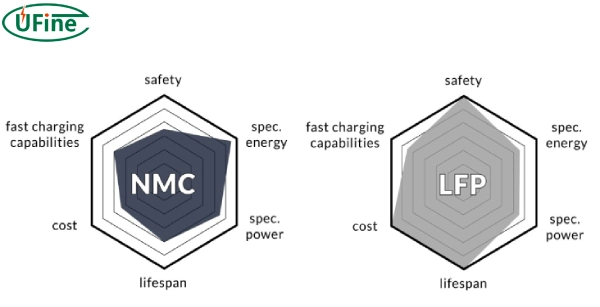

- Part 8. NMC vs LFP batteries: which should you choose?

- Part 9. Safety considerations and thermal management in NMC batteries

- Part 10. NMC battery packs and applications

- Part 11. Final Thoughts

- Part 12. FAQs

The NMC Lithium-ion battery is referred to as a nickel, manganese, or cobalt battery. It is a long-term source of energy. This luminous battery has a high energy density. It is a reliable energy source. Lithium NMC batteries are used in electric vehicles and electronics.

Moreover, it is widely used in energy storage systems and mobile devices. The popularity of these batteries is growing day by day. So, understanding their features and workings is important. The global market for Li-ion battery cells alone is forecast to reach US$380 billion by 2034. This article will shed light on the specifications, pros, and cons of NMC lithium-ion batteries.

Key Takeaways

- NMC batteries balance energy density, cost, and performance, which is why they dominate electric vehicles and portable electronics.

- The nickel–manganese–cobalt ratio directly affects energy density, stability, lifespan, and cost.

- NMC 811 is gaining popularity because it delivers higher energy density while reducing cobalt content.

- Compared with LFP batteries, NMC offers higher energy density but lower thermal stability and cycle life.

- Choosing NMC makes the most sense when space and weight matter more than ultra-long lifespan.

Part 1. What is an NMC lithium-ion battery?

An NMC lithium-ion battery uses a cathode made from nickel (Ni), manganese (Mn), and cobalt (Co) combined in different ratios. This chemistry was developed to strike a balance: high energy density without sacrificing safety and longevity too much.

That balance explains why you see NMC batteries in electric vehicles, laptops, power tools, and many commercial battery packs. You get more energy in less space than LFP, while avoiding the high cost and instability associated with very cobalt-heavy chemistries.

In other words, if you care about compact size and solid performance, NMC is often the middle ground.

Part 2. NMC battery chemistry: anode, cathode, and working principle

1 Anode and Cathode

It consists of three main parts. These are the cathode, anode, and electrolyte. These parts work together. So, they allow the movement of lithium ions during charging and discharging cycles.

- Cathode: The cathode comprises nickel, manganese, and cobalt. These three materials are used in different concentrations based on the battery design.

- Anode: Like all other lithium batteries, the anode is constructed from graphite. Graphite allows the storage and release of lithium ions while the battery is working.

- Electrolyte: The electrolyte consists of lithium ions dissolved in a liquid. The electrolyte composition varies in different batteries. The most commonly used lithium salts in electrolytes are lithium hexafluorophosphate (LiPF6) and lithium bis (trifluoromethyl sulfonyl)imide (LiTFSI). They are dissolved in organic solvents. The organic solvents that are frequently used are ethylene carbonate (EC), dimethyl carbonate (DMC), and diethyl carbonate (DEC).

At a structural level, an NMC lithium-ion battery looks similar to other lithium-ion cells, but the material choices make a big difference.

The anode is typically graphite, which stores lithium ions during charging. This part is fairly standard across most lithium-ion chemistries.

The cathode is where NMC stands apart.

Nickel increases energy density, manganese improves thermal stability, and cobalt enhances structural integrity and conductivity. Adjusting their ratio lets manufacturers fine-tune performance. Higher nickel boosts capacity, but it also makes the battery more sensitive to heat. That trade-off is one of the key design challenges with modern NMC batteries.

If you want a deeper technical breakdown of lithium-ion chemistry fundamentals, Battery University provides a solid reference.

You might wonder how the lithium NMC battery works. Like all other batteries, it works on the principle of electrochemical reactions. It is a secondary battery. The lithium ions flow via electrolyte from the positive to the negative electrode during charging. During discharging, the ions move from the negative electrode (anode) to the positive electrode(cathode). Hence, it supplies energy to power devices such as electronic cars.

2 NMC Lithium-ion battery charging

During charging, the battery undergoes the following reaction:

At Negative Plate Anode (C6):

Here is the general reaction that occurs at the anode.

C6+ xLi + e^− → LiC6

This reaction results in the formation of Lithium carbide (1/6) graphite intercalation compound.

At Positive Plate Cathode (LiNiMnCoO2):

So, the following is the reaction that is usually carried out at the cathode.

LiCoO2 → Li1−xCoO2 + xLi + e^-

So, we can say the overall reaction that takes place during the charging of the battery is as follows.

LiCoO2 + C6 → Li1−xCoO2 + LiC6

Overall, during charging, electrons move from cathode to anode. The result of the reaction is a lithium graphite intercalation compound.

3 NMC Lithium-ion battery discharging

The chemical reactions that occur during discharging are:

At Negative Plate Anode (C6):

LiC6 → C6+ xLi + e^−

At Positive Plate Cathode (LiNiMnCoO2):

Li1−xCoO2 + xLi + e^- → LiCoO2

So, the overall reaction during discharging is:

Li1−xCoO2 + LiC6 → LiCoO2 + C6

x in the above reaction is a stoichiometric variable. It indicates the amount of lithium ions dissolved in the reaction. Hence, the overall discharging of the battery releases energy. This energy is provided to the electrical devices.

Part 3. NMC battery specifications

When people search for “NMC battery specifications”, they usually want practical numbers—not theory. While exact values vary by manufacturer and design, most NMC lithium-ion batteries fall within the ranges below.

| Specification | Typical NMC Battery |

|---|---|

| Nominal voltage | 3.6–3.7 V |

| Energy density | 150–250 Wh/kg |

| Cycle life | 800–2,000 cycles |

| Operating temperature | –20°C to 60°C |

| Charge rate | 0.5C–1C |

| Self-discharge | Low |

These specifications explain why NMC batteries are so popular in EVs. You get high energy density without an extreme cost premium, although cycle life and thermal stability still require careful management.

Part 4. NMC battery degradation and aging: why performance declines over time

Even though NMC batteries are known for their strong performance, they do not maintain peak capacity forever. Like all lithium-ion chemistries, NMC cells gradually degrade as they age, and understanding why this happens helps you set realistic expectations.

One major factor is high nickel content, especially in advanced chemistries such as NMC 811. While nickel increases energy density, it also makes the cathode structure less stable over time. Repeated charging and discharging can cause microcracks inside the cathode material, which slowly reduce the battery’s ability to store and release lithium ions efficiently.

Temperature also plays a critical role. Prolonged exposure to high heat accelerates side reactions inside the cell, thickening the solid electrolyte interphase (SEI) layer on the anode. As this layer grows, internal resistance increases, leading to lower usable capacity and reduced power output.

In real-world applications, degradation is usually not caused by a single factor but by the combined effects of high temperature, high state of charge, and aggressive charging behavior. This is why two NMC batteries with the same specifications can age very differently depending on how they are used.

Part 5. NMC battery types: From 111 to 811

| Type | Ni:Mn:Co | Key Features | Typical Use |

|---|---|---|---|

| NMC 111 | 1:1:1 | Balanced, mature | Consumer electronics |

| NMC 532 | 5:3:2 | Higher energy | Early EVs |

| NMC 622 | 6:2:2 | Better energy & stability | EV, ESS |

| NMC 811 | 8:1:1 | High energy, low cobalt | Modern EVs |

NMC lithium-ion batteries come in different types. These types may have different composition, performance, and applications. So, let’s discuss them in detail.

1. NMC 111 battery

NMC 111 has a balanced composition. This means its cathode has equal parts of nickel manganese and cobalt. Moreover, it has a good energy density cycle and is relatively inexpensive. That is why they have a wide scope of applications in various industries. These industries may include electric vehicles and consumer electronics.

2. NMC 532 battery

It is composed of more nickel than manganese and cobalt. Like NMC111, it has a relatively more energy density cycle and specific energy. Besides this, it is used in such applications where increasing energy storage capacity has a significant role. For example, in electric vehicles and grid energy storage systems.

3. NMC 622 battery

These batteries contain more cobalt. At the same time, nickel and manganese have low concentrations. It helps achieve better stability and high energy density. This battery can withstand high temperatures. O, it is commonly used in electric vehicles and stationary storage systems.

4. NMC 811 battery

This type of NMC battery features a higher nickel content. They can provide higher energy density and reduce the dependency on cobalt. NMC 811 batteries have enough energy storage capacity. So, it helps improve cost-effectiveness. Thus, it is becoming popular for electric vehicles and large-scale energy storage applications.

Among these, NMC 811 has become especially important. By cutting cobalt to around 10%, manufacturers reduce cost and ethical concerns while achieving higher energy density—though thermal management becomes more critical.

Part 6. Advantages and disadvantages of NMC batteries

NMC batteries stand out because they’re versatile. You get high specific energy, fast charging capability, and strong performance across many applications. That’s why automakers and electronics brands rely on them so heavily.

However, those benefits come with trade-offs. NMC batteries are more sensitive to high temperatures than LFP, and their cycle life is shorter. They also depend on materials like cobalt and nickel, which raises cost and sustainability concerns.

Pros:

- Reliable Energy Source

- High Specific Energy

- It recharges quickly.

- Long charge-discharge cycles

- It provides safety due to its thermo-stable nature.

- High energy efficiency

Cons:

- Costly as compared to other lithium batteries.

- Ethical issues concerned with cobalt mining.

- Continuous exposure to high temperatures might cause damage.

- The increasing demand for NMC lithium batteries is difficult to meet.

- Environmental concerns due to the use of environmentally unsustainable raw material

If you’re designing or selecting a battery system, the real question isn’t whether NMC is “good” or “bad”—it’s whether energy density matters more than long-term durability in your use case.

Part 7. How can you extend the life of an NMC battery?

While you cannot completely stop battery aging, you can significantly slow it down with proper system design and usage habits. In fact, many NMC batteries fail early not because of chemistry limitations, but because of avoidable operating conditions.

One of the most effective strategies is state-of-charge management. Keeping an NMC battery constantly at 100% accelerates cathode stress, especially in high-nickel designs. In many applications, limiting the upper charge level slightly can noticeably improve long-term stability without a major loss in usable energy.

Temperature control is equally important. NMC batteries perform best within a moderate temperature range, and even short periods of excessive heat can cause lasting damage. This is why thermal management systems and proper enclosure design are critical in EVs and energy storage systems.

Finally, a well-tuned battery management system (BMS) makes a measurable difference. Accurate cell balancing, conservative charge cutoffs, and reliable thermal monitoring help protect NMC cells from conditions that accelerate degradation. When these elements work together, the actual service life of an NMC battery can exceed what the raw cycle-life numbers might suggest.

Part 8. NMC vs LFP batteries: which should you choose?

You might feel perplexed while selecting a battery for your appliances. So here is a detailed comparison between nickel, manganese, cobalt, and lithium iron phosphate batteries.

NMC lithium-ion Battery

- Specific Energy: NMC lithium has a more specific energy. So, it can comparatively store more energy in a compact mass.

- Energy Storage: NMC batteries come with less energy storage capacity than LFPs.

- Structural Framework: The structural framework of the NMC lithium-ion battery is relatively less stable. So they can easily catch fire.

- Cycle Life: NMC lithium has a short life i.e. of 800 cycles before degradation. It means that it can only undergo 800 charging and discharging cycles.

- Price: NMC lithium-ion battery has a price as compared to LFP.

- Thermal Stability: The NMC battery is less thermally stable and is at a higher risk of overheating than the LFP battery.

- Environmental Impact: Environment-unfriendly due to toxic cobalt content

- Applications: These batteries are widely used in industries like electric vehicles, smartphones, laptops, etc.

LFP Lithium Batteries

- Specific Energy: LFP lithium batteries have a lower specific energy than NMC lithium.

- Energy Storage: LFP batteries can store more energy in a large mass. They do not have a compact volume for storing large amounts of energy.

- Life Span: It has a prolonged life span of roughly ten years.

- Structural Framework: The structural framework of the LFP lithium battery is more stable and is less likely to catch fire.

- Cycle Life: LFP lithium has a high cycle life of about 3000 or more cycles.

- Price: LFP lithium battery is less expensive than NMC.

- Thermal Stability: The LFP battery is more thermally stable and is at a lower risk of overheating.

- Environmental Impact: Environment-friendly due to non-toxic raw materials.

- Applications: They are used in electric buses, grid stations, and stationary applications

This comparison will ease your battery selection process. So, let’s briefly describe it in the following table.

| Aspect | NMC Lithium Batteries | LFP Lithium Batteries |

|---|---|---|

| Cathode Material | Nickel, Manganese, Cobalt | Iron Phosphate |

| Energy Density | Higher | Lower |

| Cycle Life | Moderate to High | High |

| Safety | Moderate | High |

| Thermal Stability | Lower | Higher |

| Cost | Lower | Higher |

| Charging Speed | Faster | Slower |

| Applications | Electric vehicles, portable electronics | Solar energy storage, power tools |

Part 9. Safety considerations and thermal management in NMC batteries

Safety is often discussed in simple terms, but with NMC batteries, it deserves a more nuanced explanation. Compared with LFP chemistry, NMC batteries—particularly high-nickel variants—are more sensitive to thermal stress and overcharging. This does not make them unsafe by default, but it does mean they rely more heavily on system-level protection.

Thermal runaway in NMC batteries is typically triggered by a combination of internal short circuits, excessive heat, or uncontrolled charging. Once a critical temperature threshold is reached, exothermic reactions inside the cell can accelerate rapidly, releasing stored energy in an uncontrolled manner.

To mitigate these risks, modern NMC battery packs incorporate multiple layers of protection. These include active cooling systems, robust mechanical separation between cells, and conservative BMS logic that prioritizes safety over maximum capacity. In well-designed systems, these measures dramatically reduce the likelihood of failure, even under demanding operating conditions.

As a result, NMC batteries remain widely used in electric vehicles and high-performance applications, provided that thermal management and safety design are treated as core engineering priorities rather than afterthoughts.

Part 10. NMC battery packs and applications

In practice, you rarely use a single NMC cell. Most systems rely on NMC battery packs, which combine cells with a battery management system (BMS). The BMS is critical—it controls temperature, balances cells, and prevents overcharging or deep discharge.

This is especially important in EVs and energy storage systems, where safety and longevity depend as much on system design as on chemistry itself. A well-designed NMC battery pack can perform reliably for years, even under demanding conditions.

If you want a clearer understanding of how individual cells are assembled into modules and full systems, this guide explains the differences between battery cells, battery modules, and battery packs in detail.

Part 11. Final Thoughts

NMC lithium-ion batteries aren’t perfect, but they’re popular for a reason. If you need high energy density, reasonable cost, and proven performance, NMC remains one of the most practical choices available today.

Understanding the chemistry, specifications, and differences between NMC types—especially NMC 811—helps you choose the right battery with confidence, rather than relying on marketing claims or oversimplified comparisons.

Part 12. FAQs

Is an NMC battery suitable for fast charging?

Yes, NMC batteries generally support faster charging than many other lithium chemistries. However, frequent high-rate charging can accelerate degradation, especially in high-nickel designs such as NMC 811.

Can NMC batteries be used in cold environments?

NMC batteries can operate in low temperatures, but their performance and charging efficiency drop significantly in cold conditions. Proper thermal control is essential for reliable winter operation.

Are NMC batteries recyclable?

Yes, NMC batteries are recyclable. Valuable metals such as nickel, cobalt, and manganese can be recovered, making recycling economically attractive compared to some other lithium chemistries.

How does NMC compare to solid-state battery technology?

NMC batteries are commercially mature and widely deployed today, while solid-state batteries are still in development. For now, NMC offers better availability, lower cost, and proven reliability.

Related Tags:

More Articles

How Much Does a Golf Cart Battery Weigh?

Learn how golf cart batteries affect total golf cart weight and size, with average weight ranges and standard dimensions for electric golf carts.

Top 20 Lithium Ion Battery Manufacturers

2026 guide to top 10 lithium-ion battery manufacturers, covering small & large companies, applications, technology strengths, and selection tips.

How to Charge a LiPo Battery Safely and Correctly

Learn how to safely charge your LiPo batteries, avoid overcharging, and choose the best chargers for longer battery life and safety.

Essential LFP Battery Raw Material: LFP Cathode Material

Discover the benefits of lithium iron phosphate (LFP) battery cathodes. Learn why they’re a smart choice for energy storage today.

How to Calculate Battery Run Time?

Learn how to calculate battery run time using mAh, Wh, and watts. Covers battery run time formulas, derating factors, and lithium battery examples.