- Part 1. How long does a humanoid robot battery last?

- Part 2. Why humanoid robot batteries are bigger and heavier than you expect

- Part 3. What’s inside a humanoid robot battery pack?

- Part 4. Battery voltage

- Part 5. Can you just add a bigger battery?

- Part 6. Battery swapping

- Part 7. Safety first — Can humanoid robot batteries catch fire?

- Part 8. Market implications of pack design

- Part 9. What will change in the next 5 years?

- Part10. FAQs

One billion humanoid robots by the 2040s?

Elon Musk stated that he expects more than one billion humanoid robots to be in operation globally by the 2040s. He further disclosed that Tesla plans to deploy at least 1,000 Optimus robots within its own operations, emphasizing that “things are going to scale up very rapidly from there.” During the same meeting, Musk expressed confidence that humanoid robots would eventually outnumber humans, estimating a potential population of 20 billion or more, although no specific timeline was provided.

Humanoid robots are among the most sophisticated machines ever built. Yet, despite advances in AI and sensors, battery pack design remains the single biggest factor limiting performance. Most discussions around “battery life” focus on chemistry or cell capacity, but this is misleading: a high-capacity Li-ion cell is useless if the pack can’t deliver the power, maintain thermal stability, or fit within the robot’s weight constraints.

From an engineering standpoint, the real challenge is not just how much energy a pack can store, but how it can safely and efficiently supply power under dynamic, unpredictable loads. This perspective is critical for anyone designing, buying, or evaluating humanoid robots.

Part 1. How long does a humanoid robot battery last?

Most commercial humanoid robots operate between 1.5 and 4 hours per charge. While idle robots may last longer, high-mobility tasks like walking, balancing, or lifting often consume energy at a rate far beyond what the battery’s nominal capacity suggests.

Typical Humanoid Robot Battery Runtime by Usage

| Usage Scenario | Typical Runtime | Notes |

|---|---|---|

| Idle / Monitoring | 4–6 hrs | Sensor + low compute |

| Continuous Walking | 1.5–3 hrs | High peak current draws |

| Manipulation Tasks | 2–3 hrs | Actuator-heavy motion |

| AI Interaction & Perception | 2–4 hrs | Compute‑intensive workloads |

| Mixed Real-World | 1.5–3 hrs | Combined motion + perception |

Real-world battery life is usually 30–50% lower than manufacturer claims because lab testing rarely replicates continuous dynamic loads. Engineers designing a pack must account for peak current, voltage sag, and thermal limitations, not just average energy consumption.

This explains why swapping solutions are emerging as the practical response to runtime constraints, rather than simply adding bigger batteries.

If you’re specifically looking for real-world runtime expectations, this guide explains how long a humanoid robot battery typically lasts under different operating conditions.

Part 2. Why humanoid robot batteries are bigger and heavier than you expect

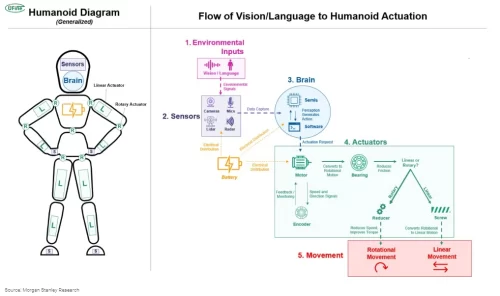

Flow Diagram of a Humanoid Robot

Why can’t the battery just be smaller?

The answer lies in the trade-offs between energy, weight, and robot stability:

- Energy vs Peak Power: High-power actuators require cells that can handle short, intense bursts—larger cells or parallel configurations are necessary.

- Weight vs Balance: A heavier pack increases energy consumption because more force is needed to move it, and misplacement can destabilize the robot.

- Form Factor: Packs must fit within structural constraints without obstructing sensors, joints, or payloads.

Simply scaling up battery capacity is rarely effective. Optimal design requires co-design of mechanics and electronics, a principle often ignored in simplified C-end explanations.

Part 3. What’s inside a humanoid robot battery pack?

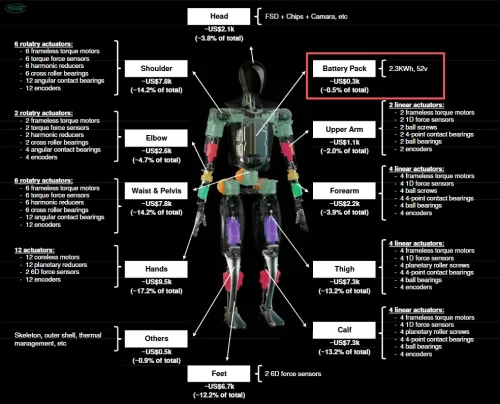

Dissecting the Humanoid Body

Most high-energy lithium-ion cells used in humanoid robot battery packs today offer energy densities in the range of 250–300 Wh/kg, while safer LiFePO4 packs typically range from 100–160 Wh/kg. Emerging solid‑state battery prototypes are targeting 350–450 Wh/kg and improved safety profiles.

Battery Chemistry Comparison for Humanoid Robots

| Battery Type | Energy Density (Wh/kg) | Safety | Typical Use |

|---|---|---|---|

| Li‑ion (NMC) | 250–300 | Medium | High performance packs |

| LiFePO4 | 100–160 | High | Safety‑oriented, long life |

| Solid‑State (Emerging) | 350–450 | Very High | Future high‑density packs |

A humanoid battery pack is a system, not just a collection of cells:

- Cells: Typically Li-ion, LiFePO₄, or emerging solid-state chemistries. The choice reflects trade-offs between energy density, safety, and peak discharge.

- Battery Management System (BMS): Monitors cell voltages, temperature, and current, balancing load to prolong life and ensure safety.

- Thermal management: High transient loads generate heat quickly; active or passive cooling is essential to prevent degradation.

- Structural housing: Provides protection from mechanical shocks and contributes to fireproofing strategies.

A “fireproof battery” is less about materials and more about holistic pack engineering. Safety, thermal stability, and mechanical design must be considered together.

AI & Humanoid Robot Battery Solution: In real-world AI and humanoid robot deployments, customized humanoid robot battery pack solutions—such as those developed by Ufine Battery—are increasingly used to balance power density, safety, and mechanical integration.

Part 4. Battery voltage

Voltage is often misunderstood by non-engineers. Most humanoid robots operate at 48–72V, significantly higher than consumer devices.

Research indicates that increasing pack voltage from 48 V to 72 V can improve overall drivetrain efficiency by 5–15%, due to reduced resistive losses at lower current levels. However, this comes with increased insulation requirements and BMS complexity not present at lower voltages.

- Higher voltage reduces current for the same power, minimizing resistive losses and improving efficiency.

- It also allows the BMS to distribute loads across multiple cells safely.

- Tesla’s humanoid robot designs leverage high-voltage architectures to balance heavy AI computation with actuator demands, but at the cost of more complex insulation and connector safety requirements.

Voltage selection is a design lever, not a fixed specification. Trade-offs include safety, thermal management, and connector robustness.

Part 5. Can you just add a bigger battery?

A common misconception: “More capacity = longer operation.” Reality is more nuanced:

- Heavier packs increase actuator load, potentially reducing net runtime.

- Space and mechanical constraints may limit how large a pack can be.

- Thermal constraints can prevent safe high-current discharge.

Engineers often achieve better runtime by optimizing pack layout and thermal management rather than simply increasing cell count. Diminishing returns are real and often counterintuitive to buyers.

Part 6. Battery swapping

Battery swapping addresses the most obvious C-end pain point: robots stopping mid-task.

- Fixed packs: Simple, low-cost, but downtime is long.

- Semi-modular packs: Provide some flexibility while limiting complexity.

- Fully swappable modules: Enable near-continuous operation but require precise mechanical and electrical integration.

China leads in humanoid robot battery swap deployment, particularly in service and industrial robots. Swapping is often more practical than waiting for chemistry breakthroughs to deliver all-day operation.

Swapping is not a gimmick; it’s a system-level solution to a physics problem.

UBTECH’s Walker S2 demonstrates how autonomous battery swapping enables humanoid robots to operate continuously with minimal downtime.

Part 7. Safety first — Can humanoid robot batteries catch fire?

Lithium-based packs carry inherent risk. But in practice, the likelihood of fire is largely controlled by pack engineering:

- Thermal runaway is mitigated by cell selection, spacing, and cooling.

- BMS oversight prevents overcurrent or overvoltage conditions.

- Mechanical isolation and housing limit cell-to-cell propagation.

Prioritizing safety is non-negotiable. Engineers must balance runtime, weight, and peak power without compromising fireproofing. Trade-offs are often invisible to C-end consumers.

Part 8. Market implications of pack design

Total Ex Software Bom for Tesla Optimus at 50 60k per Unit

Morgan Stanley’s “The Humanoid 100” report provides a comprehensive overview of the global humanoid robot value chain, including key trends shaping battery and power system design.

Battery pack design shapes not only performance but also the humanoid robot market:

- Custom packs dominate, reflecting diverse robot designs and use cases.

- Production cost is significant due to low-volume, high-complexity packs.

- Swappable and modular designs influence adoption, especially in commercial and industrial sectors.

Battery engineering drives both pricing and usability. Companies investing in smarter pack design gain competitive differentiation.

Part 9. What will change in the next 5 years?

Battery technology improvements will be incremental, not revolutionary:

- Solid-state cells may increase energy density by 30–50% and improve safety.

- Swapping systems and modular packs will reduce operational downtime.

- Software and power management will increasingly extend effective runtime without new chemistry.

Part10. FAQs

1. Can humanoid robot battery packs be customized for different tasks?

Yes. Most humanoid robot battery packs are task-specific. Robots designed for continuous walking, manipulation, or heavy payloads require different discharge profiles, cooling strategies, and pack layouts. Customization often focuses on peak current capability and thermal design, not just capacity.

2. What limits fast charging in humanoid robot batteries?

Fast charging is mainly limited by heat generation and cell degradation. High charge rates increase internal resistance losses, which can shorten battery lifespan or trigger safety limits enforced by the BMS. For humanoid robots, fast charging is often restricted to protect both cells and connectors.

3. How does battery pack placement affect humanoid robot stability?

Battery pack placement directly influences the robot’s center of mass. Packs positioned too high or too far from the torso center can increase balance correction energy, reduce walking efficiency, and raise fall risk. This is why many humanoid robots place batteries close to the pelvis or lower torso.

4. Are humanoid robot battery packs waterproof or dustproof?

It depends on the application. Service and indoor humanoid robots typically use basic ingress protection, while industrial or outdoor robots may require IP-rated enclosures. Higher protection levels add weight and cost, so they are usually reserved for harsh environments.

5. What happens if one battery cell fails inside the pack?

Well-designed packs isolate failing cells through the Battery Management System (BMS). The BMS can disconnect the pack, reduce output, or trigger safe shutdown to prevent cascading failure. Poorly designed packs, however, may allow cell-to-cell thermal propagation.

6. How does battery aging affect humanoid robot performance?

As batteries age, internal resistance increases. This causes voltage sag under load, reducing actuator torque and compute stability even if nominal capacity remains. In practice, robots may feel “weaker” before runtime noticeably declines

7. Are standardized battery packs likely in the humanoid robot market?

In the near term, standardization is unlikely. Humanoid robots vary widely in size, weight, voltage, and use cases. However, semi-standard modular designs may emerge within specific robot categories, such as service or logistics humanoids.

Related Tags:

More Articles

18650 Battery vs AA: Which Is Better for Your Device?

Compare 18650 vs AA batteries in capacity, voltage, rechargeability, and applications. Learn which battery type fits high-drain or everyday devices.

What is the Difference Between Battery Cell, Battery Control Module, and Battery Pack?

Compare battery cells, modules, and packs. Learn functions, design differences, control modules, and selection tips for EV, ESS, and industrial use.

How to Prevent LiPo Battery Explosion?

Can LiPo batteries explode or catch fire? Learn key causes of LiPo battery fires and proven charging, storage, and handling tips to reduce explosion risk.

Aluminium Ion Battery vs Lithium-Ion: A Detailed Comparison

Compare aluminium ion battery vs lithium-ion battery in energy density, charging speed, safety, cost, and uses. A practical guide for engineers and buyers.

C vs D vs AA Battery: Size, Voltage, Capacity & Key Differences Explained

Compare AA, C, and D batteries by size, voltage, capacity, and lifespan. Learn the real difference between C and D batteries and which one you should use.