Part 1. Why heated gloves require application-specific battery design?

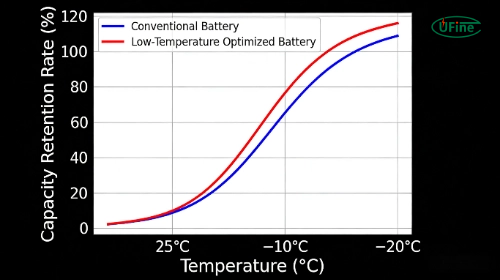

Unlike standard wearables, heated gloves operate under continuous electrical load in sub-zero environments. Independent industry research shows that lithium-ion batteries can experience significant performance degradation below 0 °C, primarily due to reduced ion mobility and increased internal resistance, which directly limits usable capacity and discharge stability. Lithium battery low-temperature performance degradation.

In practical cold-weather applications, usable battery capacity may drop sharply. For example, a lithium-ion battery rated at room temperature may deliver only around 50% of its nominal capacity at –18 °C, resulting in shortened heating duration and unstable output.

Key application constraints for heated gloves include:

- Operating temperatures commonly between –10 °C and –20 °C

- Continuous discharge for 3–8 hours, depending on heating level

- Installation space typically <15 mm thickness in glove compartments

- Frequent exposure to snow, sweat, and condensation

Part 2. Key battery performance requirements (Engineering Perspective)

Low-Temperature Discharge Stability

Cold environments directly affect lithium battery electrochemistry. Low temperatures reduce conductivity and hinder ion transport inside the cell, leading to higher impedance, voltage sag, and reduced effective capacity under load.

Design targets for heated gloves batteries:

- Stable discharge at –10 °C to –20 °C

- Voltage drop <10% under continuous heating load

- Reduced internal resistance through optimized cell selection and BMS tuning

Compact Form Factor & Weight Control

Handwear ergonomics impose strict physical constraints:

- Typical battery volume: <25–40 cm³

- Weight target: <60 g per battery module

- Preference for flat pouch cells or compact cylindrical layouts

Battery geometry must align with glove structure without compromising comfort or dexterity.

Safety in Wet & Snowy Conditions

Heated gloves operate in environments where moisture ingress, condensation, and repeated thermal cycling are unavoidable. International safety standards such as IEC 62133-2 define test requirements for electrical, mechanical, and environmental safety of lithium-ion batteries used in portable and wearable devices. IEC 62133 lithium battery safety standard overview.

Compliance with IEC 62133 and UN38.3 helps ensure reliable operation, reduced failure risk, and smoother global market access for heated glove products.

Part 3. Scenario-based battery solution recommendations

Below are application-matched battery solutions, not generic product listings.

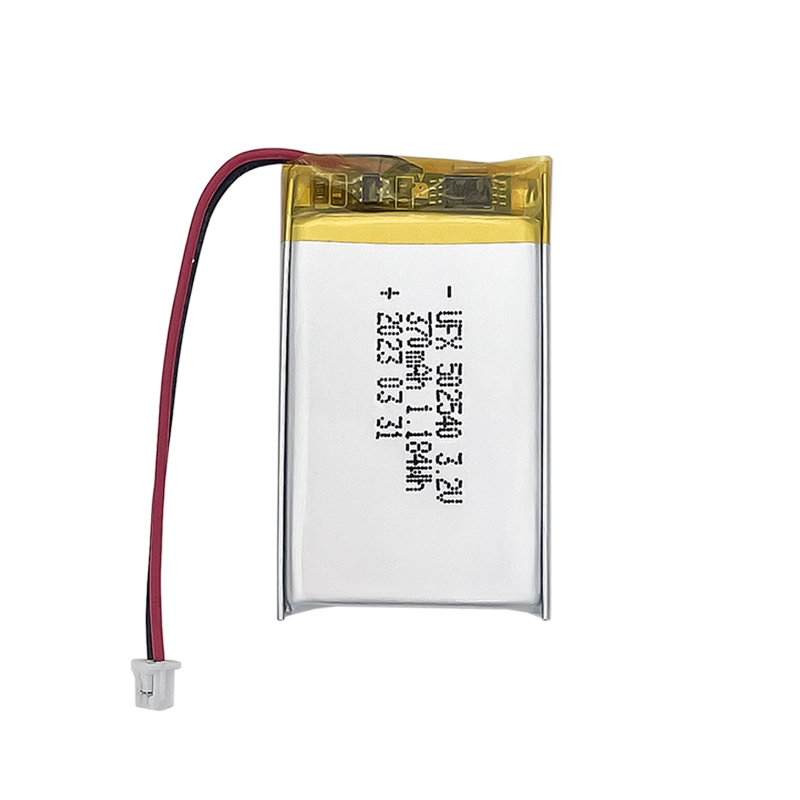

Scenario 1: Lightweight Heated Gloves for Recreational Skiing

Design goal: Slim profile, 3–5 hours runtime, minimal hand fatigue

Recommended solutions:

- 3.7V 1000mAh Li-ion Battery (102050)

Compact pouch design, ideal for internal glove pockets - 3.7V 850mAh Li-ion Battery (503055)

Balanced energy density and weight for featherweight heated gloves

Scenario 2: High-Performance Heated Gloves for Alpine & Backcountry Skiing

Design goal: Longer heating duration, stable output under extreme cold

Recommended solutions:

- 7.4V 1500mAh Li-ion Battery Pack (123450-2S)

Higher voltage improves heating efficiency and control stability - 7.4V 2000mAh Li-ion Battery Pack (103450-2S)

Suitable for multi-hour skiing sessions in sub-zero conditions

Scenario 3: Extended Runtime Heated Gloves for Multi-Day Ski Trips

Design goal: Maximum runtime with external or modular battery placement

Recommended solutions:

- 7.4V 5200mAh 18650 Battery Pack (18650-2S2P)

- 3.7V 7500mAh 18650 Battery Pack (18650-3P)

Part 4. Battery decision parameters (OEM & Engineering Reference)

| Parameter | Typical Range for Heated Gloves |

|---|---|

| Nominal Voltage | 3.7V / 7.4V |

| Capacity | 800–5200mAh (internal) / up to 7500mAh (external) |

| Cell Type | Li-ion pouch / 18650 cylindrical |

| Operating Temperature | –20 °C to +60 °C |

| Protection | OVP, UVP, SCP, NTC |

| Certifications | UN38.3, MSDS, IEC 62133 support |

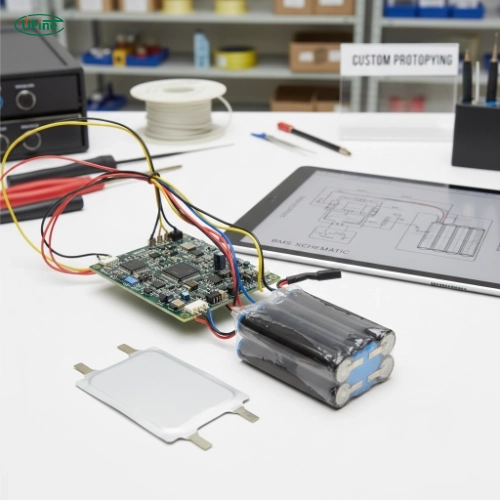

Customization & Manufacturing Support

As a lithium battery heated gloves factory, Ufine provides:

- Custom battery dimensions based on glove CAD drawings

- Connector and cable customization for heating controllers

- Low-temperature optimized cell selection

- Small-batch OEM support for prototype and pilot production

Talk to Ufine’s battery engineers to receive application-matched battery recommendations, drawing support, and compliance guidance for your heated gloves project.

Get Custom Heated Gloves Battery SolutionsHigh Energy Density

It stores large amounts of energy in a smaller and lighter package

Longer Cycle Life

Withstands extensive charge and discharge cycles

Low Self-Discharge

Maintains power longer when not in use

Safety

Minimizes the risk of accidents and ensures safe operation

More Information About Heated Gloves Battery

-

What battery chemistry works best for heated gloves in low temperatures?

-

What voltage is typically used in heated gloves battery systems?

-

Can heated glove batteries be customized for slim or irregular glove spaces?

-

What safety protections are required for heated gloves used in snow and moisture?

-

Do you support small-batch OEM or pilot production for heated gloves?

Latest Blogs

About Lithium Battery Industry News

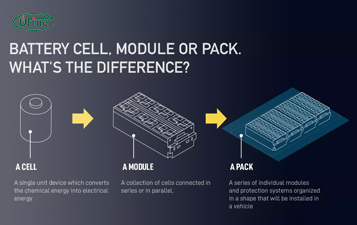

What is the Difference Between Battery Cell, Battery Control Module, and Battery Pack?

Compare battery cells, modules, and packs. Learn functions, design differences, control modules, and selection tips for EV, ESS, and industrial use.

2026/02/28 Ufine

How to Prevent LiPo Battery Explosion?

Can LiPo batteries explode or catch fire? Learn key causes of LiPo battery fires and proven charging, storage, and handling tips to reduce explosion risk.

2026/02/28 Ufine

Aluminium Ion Battery vs Lithium-Ion: A Detailed Comparison

Compare aluminium ion battery vs lithium-ion battery in energy density, charging speed, safety, cost, and uses. A practical guide for engineers and buyers.

2026/02/28 Ufine

C vs D vs AA Battery: Size, Voltage, Capacity & Key Differences Explained

Compare AA, C, and D batteries by size, voltage, capacity, and lifespan. Learn the real difference between C and D batteries and which one you should use.

2026/02/28 Ufine

What is a battery MSDS? Learn what a lithium battery MSDS certificate includes, why it’s required for shipping and compliance, and how to read it correctly.

2026/02/27 Ufine

NiMH Battery vs Li-Ion Battery vs NiCad Battery: How are They Different?

Compare NiMH, Li-Ion, and NiCd rechargeable batteries by energy density, lifespan, cost, safety, and applications. Selection guide for engineers and buyers.

2026/02/27 Ufine