- Part 1. What Ufine delivers to the heated clothing industry

- Part 2. Core pain points in heated clothing applications

- Part 3. Battery performance requirements for heated apparel

- Part 4. Heated clothing applications & recommended battery solutions

- Part 5. Battery selection decision parameters (Engineering Reference)

- Part 6. Why heated clothing manufacturers choose Ufine Battery

Part 1. What Ufine delivers to the heated clothing industry

Ufine provides application-specific battery solutions for heated clothing and battery-powered apparel, helping manufacturers solve the core challenges of runtime stability, cold-weather performance, comfort, and global compliance.

For products such as heated battery apparel, heated vests, heated pants, and battery clothing, battery selection directly impacts heating duration, garment weight, and end-user satisfaction. Ufine focuses on matching battery chemistry, voltage, and capacity to real heating loads, rather than offering generic battery packs.

Part 2. Core pain points in heated clothing applications

Manufacturers of battery outfit and battery clothes commonly face the following issues during product development and mass production:

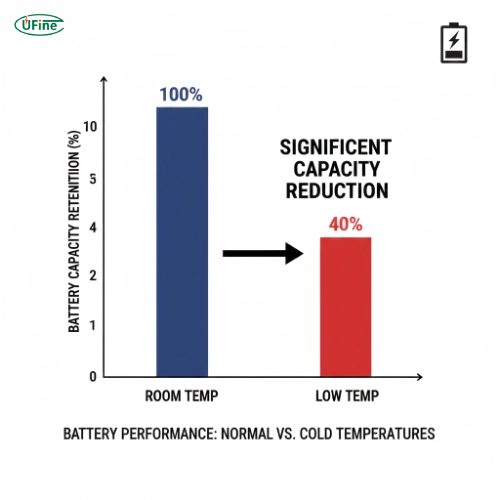

- Heating duration drops sharply in cold environments

Lithium batteries may lose up to 30–40% usable capacity below 0°C, significantly shortening heating time if not optimized. - Multi-zone heating increases discharge stress

Heated jackets and vests often power chest, back, and abdomen zones simultaneously, requiring stable continuous discharge. - Strict space and comfort constraints

Batteries must remain compact and lightweight to avoid affecting wearability. - Market expectations for runtime

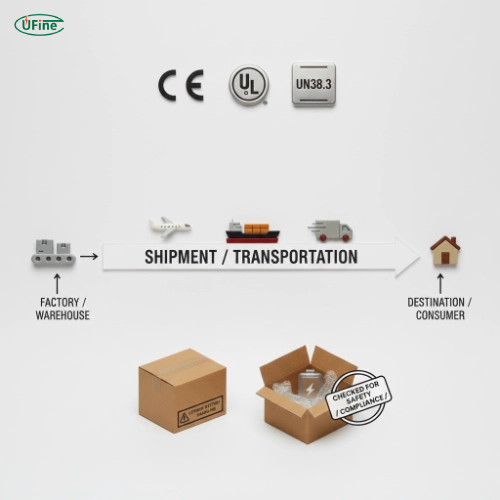

End users typically expect 4–8 hours of heating at medium settings for outdoor or professional use. - Regulatory and transport compliance

Heated rechargeable batteries must comply with CE, UL, and UN38.3 standards for global distribution.

According to widely cited industry data on lithium-ion behavior in wearables, energy density and discharge stability are decisive factors in heated apparel systems, as explained in Battery University’s overview of lithium-ion characteristics.

Part 3. Battery performance requirements for heated apparel

To support modern battery for heated clothing designs, batteries must deliver:

- Stable nominal voltage (commonly 7.4V, 11.1V, or 12V battery pack for heated clothing)

- Sufficient capacity to sustain heating elements over long durations

- Low-temperature discharge stability

- Compact and wearable-friendly form factors

- Certified safety for wearable electronics

Industry guidance on lithium-ion performance and safety can be found in Battery University’s analysis of lithium-ion battery behavior, which is frequently referenced by battery engineers and product designers.

Part 4. Heated clothing applications & recommended battery solutions

Engineering Selection Quick Reference Table

| Application Scenario | Typical Garment Type | Heating Load Characteristics | Recommended Battery Models | Engineering Rationale |

|---|---|---|---|---|

| Outdoor Sports & Winter Activities | Ski jackets, heated pants, cycling apparel | Multi-zone heating, cold exposure, continuous discharge |

|

Stable 7.4V output with enough capacity for multi-zone heating in cold conditions, without adding extra weight |

| Professional & Industrial Heated Workwear | Security jackets, construction vests, logistics clothing | Long-duty runtime, high energy reserve, continuous load |

|

Supports long-duration heating for full shifts, with higher voltage for demanding modules |

| Lightweight Everyday Heated Apparel | Heated vests, casual jackets, gloves, socks | Compact size, moderate heating power, comfort-focused |

|

Slim single-cell design for comfort, ideal for lightweight garments with limited installation space |

| Smart Heated Apparel with Device Charging | App-controlled jackets, USB-powered heated clothing | Heating + control electronics, stable regulation |

|

Balances heating and smart control, while supporting device charging |

Outdoor Sports & Winter Activities

(Ski jackets, hiking gear, cycling apparel, heated pants)

Application requirements

- Continuous heating during prolonged outdoor exposure

- Stable output under cold conditions

- Balanced capacity-to-weight ratio

Recommended solutions

- 7.4V 4400mAh 18650 Battery Pack (2P2S)

This configuration provides stable voltage and sufficient capacity to support multi-zone heating in cold environments without excessive weight. - 7.4V 5200mAh 18650 Battery Pack (2S2P)

Suitable for extended outdoor use where longer heating time is required for heated battery apparel.

Professional & Industrial Heated Workwear

(Security, construction, logistics, outdoor maintenance)

Application requirements

- Long runtime for full work shifts

- Higher energy reserves for consistent heating

- Proven reliability under continuous load

Recommended solutions

- 7.4V 10000mAh Lithium-ion Battery Pack

Designed for long-duration heating, this pack supports professional heated clothing used throughout an entire shift. - 11.1V 2000mAh 18650 Battery Pack (3S)

A higher-voltage option suitable for garments using more demanding heating modules.

Lightweight Everyday Heated Apparel

(Heated vests, casual jackets, gloves, socks)

Application requirements

- Slim and lightweight batteries

- Moderate heating duration

- High comfort for daily wear

Recommended solutions

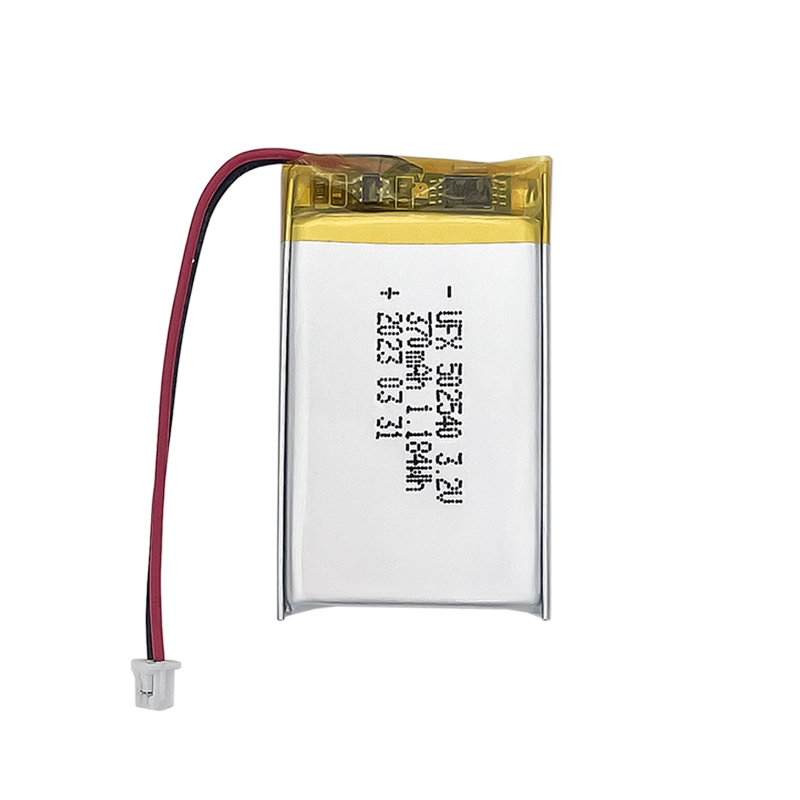

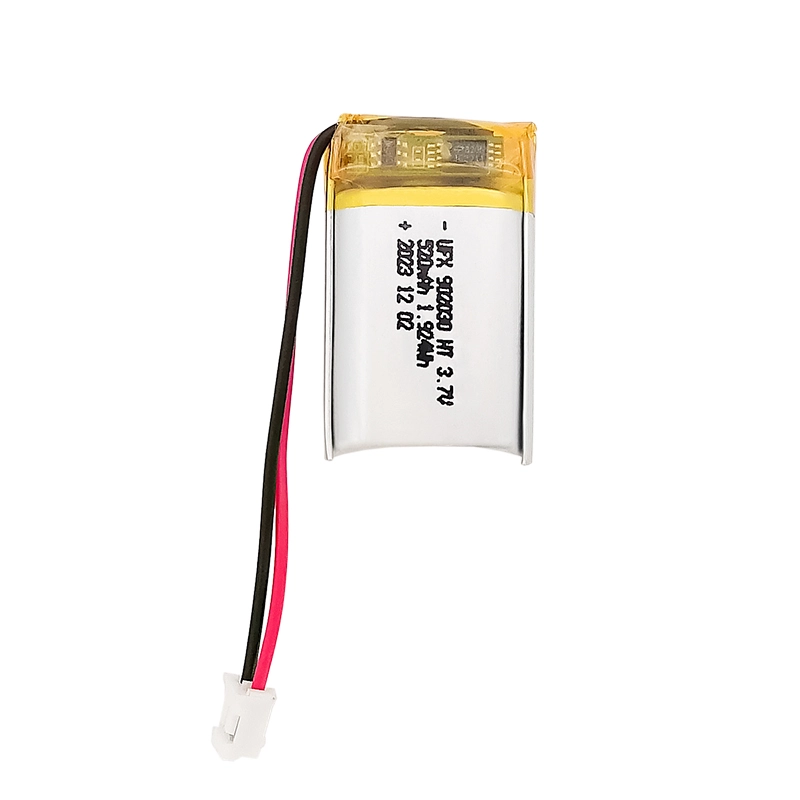

- 3.7V 2000mAh Lithium-ion Battery

A compact option well suited for heated vests and lightweight battery clothing. - 3.7V 1200mAh Lithium-ion Battery

Ideal for gloves or socks where space is limited but consistent heating is required.

Smart Heated Apparel with Device Charging

(App-controlled jackets, heated clothing with USB output)

Application requirements

- Stable voltage regulation

- Support for heating and device charging

- Integrated protection circuitry

Recommended solutions

- 7.4V 1500mAh Lithium-ion Battery Pack

This battery balances heating performance with smart control systems and USB output. - 3.7V 5000mAh Lithium-ion Battery

Provides sufficient capacity for both heating functions and mobile device charging in smart heated apparel.

Part 5. Battery selection decision parameters (Engineering Reference)

| Decision Factor | Typical Range | Impact on Heated Clothing |

|---|---|---|

| Nominal Voltage | 7.4V / 11.1V / 12V | Determines heating efficiency and controller design |

| Capacity | 1200–10000mAh | Directly affects heating duration |

| Discharge Stability | Continuous | Required for multi-zone heating |

| Cold Performance | -10°C to +60°C | Critical for outdoor and winter use |

| Safety Certification | CE, UL, UN38.3 | Required for global sales |

Part 6. Why heated clothing manufacturers choose Ufine Battery

- Application-first battery design

Battery configurations are defined by heating power, runtime targets, and garment structure—rather than adapting generic battery packs after the design is fixed. - Validated performance under wearable heating loads

Battery selections are evaluated against continuous heating discharge profiles commonly found in heated vests, jackets, and pants, not just nominal capacity ratings. - Wearability-focused form factor control

Battery structure and weight distribution are engineered to fit garment-integrated pockets and linings without compromising comfort or movement. - Production-ready compliance, not post-design certification

Safety and transport requirements such as CE, UL, and UN38.3 are considered during battery design, reducing approval risk before mass production. - Engineering alignment across development stages

Support extends from early battery selection through pre-production validation, helping manufacturers avoid late-stage redesigns and production delays.

Whether you are developing heated vests, jackets, pants, or smart heated apparel, Ufine’s engineering team can help you identify the optimal battery configuration based on heating load, runtime targets, and garment integration requirements.

Share your heating power, voltage preference, and expected operating conditions, and receive a battery recommendation aligned with real application constraints and compliance requirements.

Talk to Ufine about your heated clothing battery solutionHigh Energy Density

It stores large amounts of energy in a smaller and lighter package

Longer Cycle Life

Withstands extensive charge and discharge cycles

Low Self-Discharge

Maintains power longer when not in use

Safety

Minimizes the risk of accidents and ensures safe operation

More Information About Heated Clothing Battery

-

How do I choose between 7.4V and 11.1V battery systems for heated clothing?

-

What battery capacity is recommended for 6 hours of heating?

-

Can heated clothing batteries operate reliably in cold outdoor environments?

-

Can battery size and structure be customized for different garments?

-

What certifications are required for exporting heated clothing batteries?

Latest Blogs

About Lithium Battery Industry News

Lithium-Ion vs Lead-Acid AMR & AGV Batteries Compared

Discover the pros and cons of lithium-ion and lead-acid AMR & AGV batteries. Learn about cost, lifespan, safety, and which is right for your fleet.

2026/01/14 Ufine

Robot Vacuum Battery Replacement: Easy Step-by-Step Guide

Learn how to replace a robot vacuum battery safely and easily. Step-by-step instructions, battery types, costs, and common mistakes to avoid.

2026/01/14 Ufine

Discover how to choose the right battery for your robot. Compare Li-ion, LiFePO₄, NiMH, and more for performance, safety, and cost.

2026/01/14 Ufine

Inside Humanoid Robot Battery Pack Design

A deep dive into humanoid robot battery pack design, covering battery life, voltage, capacity, safety, and real-world engineering trade-offs.

2026/01/14 Ufine

Humanoid Robot Battery Life: How Long Do They Really Last?

Most humanoid robots run 1.5–4 hours per charge. Learn real-world battery life, battery types, capacity limits, and future improvements.

2026/01/13 Ufine

Battery Load Test: A Comprehensive Guide

Step-by-step battery load test guide for car, solar & industrial use. Learn how to load test a battery, interpret voltage charts, and avoid common mistakes.

2025/12/18 Ufine