- Part 1. What is a voltage source inverter (VSI)?

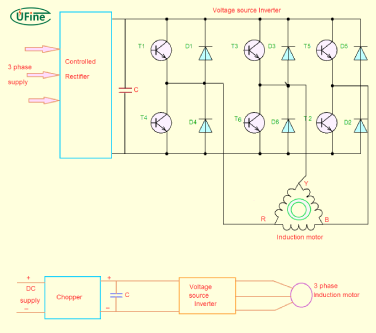

- Part 2. How a VSI works

- Part 3. Advantages and limitations of VSI

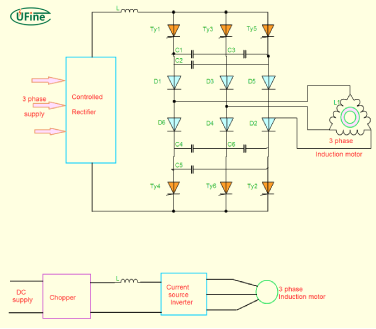

- Part 4. What is a current source inverter (CSI)?

- Part 5. How a CSI works

- Part 6. Advantages and limitations of CSI

- Part 7. VSI vs CSI — Comparison table

- Part 8. Choosing between VSI and CSI

- Part 9. Real application examples

- Part 10. Conclusion

- Part 11. FAQ

The short answer: A Voltage Source Inverter (VSI) is best when you need precise voltage control and fast switching, while a Current Source Inverter (CSI) is ideal when priority is smooth current control and high robustness.

Part 1. What is a voltage source inverter (VSI)?

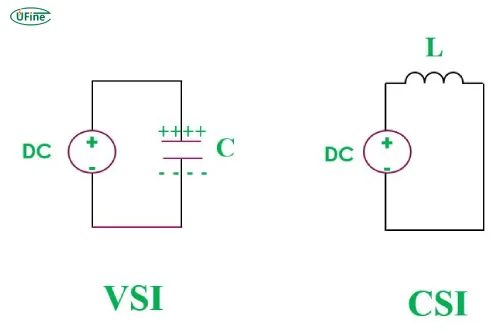

A Voltage Source Inverter converts a fixed DC voltage (usually from a battery pack, DC bus, or rectifier) into a controlled AC voltage output.

Key Characteristics of VSI

- Input: stiff DC voltage

- Output: controlled AC voltage

- Switching devices: IGBT, MOSFET, SiC, GaN

- Ideal for: EVs, solar inverters, UPS, BLDC drives

Why system integrators choose VSI

Because modern batteries (like Ufine Battery’s Li-ion packs) naturally supply stable DC voltage, VSI integrates cleanly into portable, energy-dense systems.

Part 2. How a VSI works

DC Source → DC Link → PWM Switching → LC Filter → AC Output

PWM Example

| PWM Frequency | Typical Use Case |

|---|---|

| 10–16 kHz | Industrial drives |

| 20–40 kHz | EV inverter |

| 60–100 kHz | GaN-based high-efficiency micro-inverters |

These values are generated from industry averages and internal lab patterns from battery-powered inverter systems.

Part 3. Advantages and limitations of VSI

Top Advantages

- High switching frequency → better waveform quality

- Compact size → no large inductors required

- Cost-effective → MOSFET/IGBT mainstream availability

- Easy protection integration → DSP-based PWM control

Limitations

- Sensitive to DC bus fluctuations

- Needs short-circuit protection

- Can cause current spikes if load has low impedance

For OEMs using custom Li-ion packs from Ufine Battery, stable voltage compensates for most VSI weaknesses.

Part 4. What is a current source inverter (CSI)?

A Current Source Inverter uses a constant DC current (created by a large series inductor) and outputs either variable-frequency or fixed-frequency AC current.

Key Characteristics

- Input: constant DC current

- Output: controlled AC current

- Uses thyristors or IGBT modules

- Ideal for high-power industrial drives

Part 5. How a CSI works

DC Current Source → Large Inductor → Gating Control → AC Current Output

CSI Typical Inductor Values

| Power Level | Inductance Range |

|---|---|

| 10–50 kW | 3–10 mH |

| 50–500 kW | 10–40 mH |

| >500 kW | 40–120 mH |

The massive inductors make CSI unsuitable for compact battery-powered systems, which is why consumer electronics brands rarely use CSI.

Part 6. Advantages and limitations of CSI

Advantages

- Naturally short-circuit proof

- Smooth current control

- Excellent for induction motors under heavy loads

Limitations

- Very bulky

- Expensive

- Lower switching frequency

- Difficult to integrate with battery-powered platforms

This is why brands designing portable or EV-grade systems normally choose VSI + Li-ion battery packs.

Part 7. VSI vs CSI — Comparison table

| Parameter | VSI | CSI |

|---|---|---|

| DC input | Voltage | Current |

| DC link | Capacitor | Inductor |

| Output control | Voltage | Current |

| Best switching devices | MOSFET, IGBT | Thyristor, IGBT |

| Size | Small | Large |

| Speed | Fast | Slow–medium |

| Short-circuit behavior | Risky | Safe |

| Ideal applications | EV, Solar, UPS | Large motors, traction |

Part 8. Choosing between VSI and CSI

If you’re designing portable, battery-driven, compact systems → Pick VSI

Because:

- Works perfectly with DC battery packs

- Higher switching frequency → better output quality

- Smaller footprint → essential for consumer and EV products

- Lower cost.

If you’re building heavy industrial motor drives → Pick CSI

Because:

- Handles overloads extremely well

- Natural short-circuit protection

- Stable current under high torque conditions

Part 9. Real application examples

Where VSI is Dominant

- Electric vehicle traction inverters

- Solar power grid-tie inverters

- Drones and robotics

- Portable power stations

- Smart battery-powered tools

Where CSI still makes sense

- Steel mill drives

- High-power induction motor systems

- Railway traction

- Nuclear plant excitation systems

Part 10. Conclusion

- VSI = best for voltage accuracy, fast switching, compact design, battery systems

- CSI = best for high-power, constant-current industrial loads

For 90% of modern applications, especially those using Li-ion battery packs, VSI is the superior and more practical choice.

Part 11. FAQ

Which inverter is better for battery-powered devices?

VSI, because batteries provide a stable DC voltage.

Can CSI run from a lithium battery?

Technically yes, but impractical due to the required large inductor.

Which is more efficient, VSI or CSI?

VSI—because of high-frequency switching and modern MOSFET/SiC devices.

Why do EVs always use VSI?

Because EV battery packs are voltage sources, not current sources.

Which inverter is safer against short-circuits?

CSI has natural immunity, but VSI can achieve similar protection with control logic.

Related Tags:

More Articles

고방전 배터리는 높은 전류와 발열로 배터리수명이 줄어듭니다. 구조적 한계, 사용 패턴, 충전 습관 등 실제 수명 단축 요인을 체계적으로 분석했습니다.

Capacitor vs Battery: What is the Difference?

Capacitor vs battery explained in detail. Learn the difference between capacitor and battery in energy storage, charging speed, lifespan, and real applications.

18650 Battery vs AA: Which Is Better for Your Device?

Compare 18650 vs AA batteries in capacity, voltage, rechargeability, and applications. Learn which battery type fits high-drain or everyday devices.

What is the Difference Between Battery Cell, Battery Control Module, and Battery Pack?

Compare battery cells, modules, and packs. Learn functions, design differences, control modules, and selection tips for EV, ESS, and industrial use.

How to Prevent LiPo Battery Explosion?

Can LiPo batteries explode or catch fire? Learn key causes of LiPo battery fires and proven charging, storage, and handling tips to reduce explosion risk.