- Part 1. What is a 18650 battery?

- Part 2. What are tolerances in battery measurements?

- Part 3. Why are tolerances important in 18650 battery measurements?

- Part 4. Key 18650 battery measurements and their tolerances

- Part 5. How do manufacturers ensure tolerance control?

- Part 6. Best practices for measuring 18650 battery parameters

- Part 7. How to match 18650 batteries effectively?

- Part 8. Common errors in measuring 18650 batteries

- Part 9. Tolerance standards from top manufacturers

- Part 10. How to apply tolerance knowledge in real-world applications?

- Part 11. FAQs about 18650 battery measurements

Understanding tolerances in 18650 battery measurements is essential for engineers, technicians, and DIY builders working with lithium-ion cells. Whether you’re designing a battery pack for an electric vehicle, testing cells for a power bank, or simply replacing batteries in a flashlight, accurate measurements ensure safety, consistency, and optimal performance.

What does tolerance mean in 18650 battery measurements?

In simple terms, tolerance refers to the acceptable deviation range from a specified value. In the context of 18650 batteries, this includes voltage, capacity, internal resistance, and physical size. These tolerances are not just technical details. They are vital in ensuring battery cells perform reliably under various operating conditions. Even minor deviations can lead to problems such as overheating, poor cycle life, or even serious safety hazards.

Discuss this topic in detail through practical examples, professional guidelines, and real-world applications.

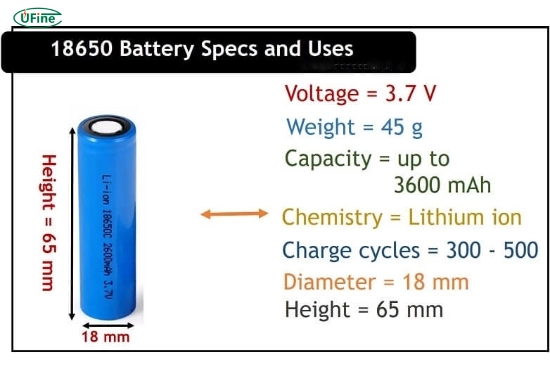

Part 1. What is a 18650 battery?

An 18650 battery is a type of lithium-ion cell named after its dimensions. It measures approximately 18 millimeters in diameter and 65 millimeters in length. Due to their high energy density and long cycle life, these rechargeable batteries are widely used in laptops, flashlights, power tools, electric bikes, and even medical devices.

The 18650 cell typically has a nominal voltage of 3.6 or 3.7 volts, and capacities range from 1800 milliamp-hours to over 3500 milliamp-hours, depending on the chemistry and manufacturer. Accurate measurements of these parameters are crucial because slight deviations can affect the battery’s behaviour in a pack or standalone.

Part 2. What are tolerances in battery measurements?

Battery measurement tolerance refers to the allowable variation from the nominal or rated values. For example, a battery rated at 3.7 volts with a tolerance of ±0.05 volts may measure between 3.65 and 3.75 volts and still be considered within specification.

These tolerances apply to several core characteristics of a battery:

- Voltage

- Capacity

- Internal resistance

- Physical dimensions

- Weight

Each of these plays a significant role in the battery’s operation, especially when multiple cells are combined in series or parallel. Tolerances ensure that cells work together harmoniously without causing imbalance or excessive wear.

Part 3. Why are tolerances important in 18650 battery measurements?

Understanding and managing tolerances is vital for several reasons:

1. Safety

Battery packs that contain cells outside of acceptable tolerance ranges are more likely to experience overcharging, overheating, or even thermal runaway. This is a serious safety concern, especially in high-drain applications.

2. Performance

Cells that vary too widely in capacity or internal resistance can cause uneven discharge and charging behavior. This leads to inefficient energy use and reduced overall performance.

3. Longevity

When cells are balanced and operate within tight tolerance ranges, they age more evenly. This significantly extends the lifespan of individual cells and the overall battery pack.

4. Consistency

Tolerances ensure that products using these batteries behave predictably. For example, a flashlight should provide the same brightness and runtime across multiple units.

Part 4. Key 18650 battery measurements and their tolerances

Let us break down each core measurement in assessing a battery’s performance and tolerance range.

Voltage

- Nominal Voltage: Typically 3.6 or 3.7 volts

- Full Charge Voltage: Up to 4.2 volts

- Discharge Cutoff Voltage: Around 2.5 volts

- Acceptable Tolerance: ±0.05 volts

Capacity

- Measured in milliamp-hours (mAh)

- Typical capacities range from 1800 to 3500 mAh

- Acceptable Tolerance: ±5 to 10 percent depending on manufacturer

Internal Resistance

- Measured in milliohms (mΩ)

- Lower resistance indicates better performance

- Acceptable Tolerance: ±10 percent for matching in packs

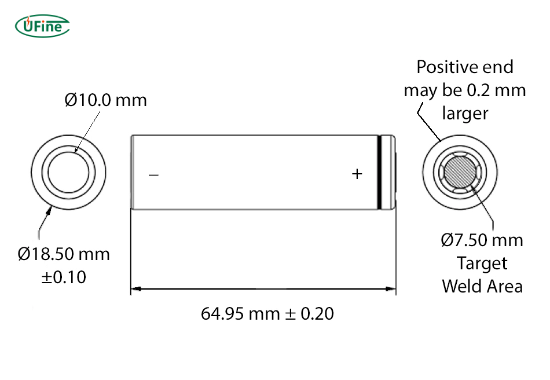

Physical Dimensions

- Diameter: 18.0 ± 0.2 millimeters

- Length: 65.0 ± 0.5 millimeters

- Acceptable Tolerance: As specified in product datasheets

Weight

- Varies depending on chemistry and capacity

- Typical range: 40 to 50 grams

- Acceptable Tolerance: ±1 gram

Part 5. How do manufacturers ensure tolerance control?

Manufacturers employ strict quality control procedures to maintain tolerance standards. These include:

- Automated sorting machines to classify batteries by voltage, capacity, and resistance

- End-of-line testing stations that check every cell before packaging

- Statistical process control (SPC) to track deviations

- Environmental testing chambers to verify performance under different temperatures

In addition, many manufacturers provide bin codes or batch numbers that help users identify groups of matched cells, which is especially useful for assembling battery packs.

Part 6. Best practices for measuring 18650 battery parameters

To get accurate and consistent results, it is essential to follow these best practices:

Use precise, calibrated tools

Always use a high-quality multimeter, battery analyzer, or internal resistance tester. Tools should be calibrated regularly to avoid reading drift.

Maintain a consistent temperature

Temperature affects both voltage and resistance measurements. Perform all tests in a stable environment, ideally between 20 to 25 degrees Celsius.

Standardize charge and discharge rates

Measurements should be done using a consistent current rate, such as 0.5C or 1C. This allows for repeatable and comparable results.

Allow resting periods

After charging or discharging, allow the battery to rest for at least 30 minutes before taking measurements. This gives the voltage time to stabilize.

Record all data

Maintain detailed measurements logs, including date, temperature, charge cycles, and any anomalies. This helps in long-term monitoring and decision-making.

Part 7. How to match 18650 batteries effectively?

Matching cells is critically important when building a battery pack. Unmatched cells can lead to inefficient energy use and premature failure.

Match by voltage

Ensure all cells are within 0.01 volts of each other. Even a small voltage difference can lead to an imbalance in series configurations.

Match by capacity

Use cells with less than a 5 per cent variation in capacity. This ensures equal energy delivery across all cells.

Matched by internal resistance

Match cells with similar resistance values, ideally within 10 per cent of each other. This helps reduce heat generation and improves overall efficiency.

Part 8. Common errors in measuring 18650 batteries

Avoiding these mistakes can significantly improve your measurement accuracy and battery life.

- Measuring too soon after charging: The voltage may still be settling

- Using low-cost testers: Cheap tools often have poor accuracy and resolution

- Ignoring temperature effects: Warm or cold batteries give misleading readings

- Not rechecking calibration: Instruments drift over time

- Failing to log results: Without records, it’s hard to know if a battery is degrading

Part 9. Tolerance standards from top manufacturers

Different manufacturers have their own standards for tolerances based on the application and quality level. Here are five reputable brands:

| Manufacturer | Voltage Tolerance | Capacity Tolerance | Dimension Tolerance | Resistance Tolerance |

|---|---|---|---|---|

| Panasonic | ±0.05 V | ±5% | ±0.2 mm | ±10% |

| Samsung SDI | ±0.03 V | ±4% | ±0.15 mm | ±8% |

| LG Chem | ±0.04 V | ±5% | ±0.2 mm | ±10% |

| Sony (Murata) | ±0.05 V | ±5% | ±0.2 mm | ±10% |

| Ufine Battery | ±0.05 V | ±5% | ±0.2 mm | ±10% |

These values are typically published in the manufacturer’s datasheets. Always select cells with tighter tolerances for critical applications like electric vehicles or medical devices.

Part 10. How to apply tolerance knowledge in real-world applications?

Applying tolerance principles can greatly improve reliability in a real-world scenario, such as building a custom battery pack for a drone or an e-bike.

For example:

- You start by testing 50 new 18650 cells for voltage, capacity, and resistance

- You sort them into groups where each group has cells with voltage within 0.01 volts, capacity within 100 mAh, and resistance within 10 milliohms

- These matched groups are then used to build balanced series-parallel battery packs

- You also install a Battery Management System (BMS) that monitors each cell to ensure it stays within voltage and current tolerances

This method results in a battery pack that charges evenly, discharges reliably, and lasts longer.

Part 11. FAQs about 18650 battery measurements

What is the tolerance range for 18650 battery voltage?

The acceptable voltage tolerance is typically ±0.05 volts from the nominal value. Always measure at room temperature and after the battery has rested.

How much variation is okay in 18650 battery capacity?

Most manufacturers allow a capacity tolerance of ±5 to 10 percent. For example, a 3000 mAh cell may actually measure between 2850 and 3150 mAh.

Why is internal resistance important in 18650 batteries?

Internal resistance affects the amount of current a battery can deliver. Higher resistance leads to more heat and voltage drop. Matching cells by resistance helps improve efficiency and safety.

Can I mix cells with different capacities or voltages?

Mixing unmatched cells can lead to imbalance, reduced performance, and safety hazards. Always use matched cells in battery packs.

How can I measure 18650 battery parameters accurately?

Use a calibrated battery analyzer or professional-grade multimeter. Test in a controlled environment and allow the battery to rest before measurement.

Related Tags:

More Articles

Battery State of Charge and Battery State of Health

Battery SoC vs. SoH explained: Learn professional methods to measure charge levels, test health status, and optimize battery performance for longer lifespan.

Difference Between 18650, 26650, and 21700 Batteries

What’s the difference between 18650, 21700, and 26650 batteries? Compare size, capacity, and performance to find the best lithium battery for your device.

LFP Battery Vs. LTO Battery: A Detailed Comparison

Compare LFP (LiFePO4) and LTO (Lithium Titanate) batteries by energy density, lifespan, safety, cost, and uses in EVs, solar storage, and backup power.

Compare 18650 battery types: Li-ion, LiFePO4, and LiPo. Key specs (voltage/capacity) and best uses for vapes, flashlights, EV batteries.

How to Distinguish Between Grade A, Grade B, and Grade C LiFePO4 cells?

Explore the differences between Grade A, B, and C LiFePO4 cells and learn how to choose the right one for electric vehicles, solar storage, or backup power.