- Quick Answer

- Part 1. AMR vs AGV: why battery choice matters

- Part 2. Battery technology overview

- Part 3. Side-by-side comparison: lithium-ion vs lead-acid

- Part 4. Runtime & charging strategy comparison

- Part 5. Total cost of ownership (TCO): The real cost over time

- Part 6. Safety & compliance in industrial environments

- Part 7. Operational maintenance & troubleshooting

- Part 8. Decision checklist: which battery should you choose?

- Part 9. FAQs

Choosing the right battery for your AMR or AGV isn’t just a technical detail—it directly affects runtime, uptime, safety, and long-term operating cost.

Lithium-ion batteries are rapidly replacing traditional lead-acid batteries in modern automation projects, but does that mean lead-acid is already obsolete? Not necessarily.

In this article, we’ll break down the real differences between lithium-ion and lead-acid batteries for AMR and AGV systems, using practical examples instead of marketing hype.

Quick Answer

Most modern AMRs and new AGV deployments benefit from lithium-ion batteries. They charge faster, last longer, require almost no maintenance, and enable opportunity charging.

Lead-acid batteries still work for:

- Legacy AGVs

- Single-shift operations

- Budget-constrained deployments

Key decision factors: runtime, charging strategy, safety, total cost of ownership (TCO), and maintenance requirements.

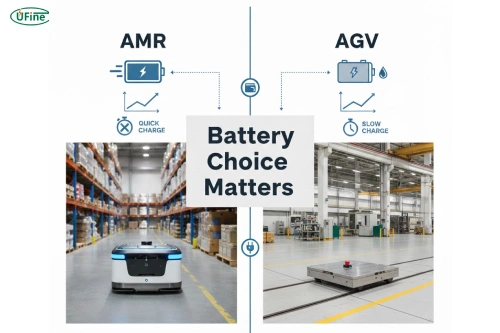

Part 1. AMR vs AGV: why battery choice matters

Although AMRs and AGVs are often grouped together, their operating patterns differ—and batteries feel that difference immediately.

AGVs usually:

- Follow fixed routes

- Run predictable cycles

- Stop for scheduled charging

AMRs, on the other hand:

- Navigate dynamically

- Start and stop frequently

- Share charging stations

- Rely heavily on opportunity charging

Because of this, AMRs place much higher demands on battery responsiveness, charging speed, and energy density, which is why lithium-ion batteries gained traction first in AMRs before spreading to AGVs.

Part 2. Battery technology overview

1 Lead-Acid Batteries (Flooded, AGM, Gel)

Lead-acid batteries have powered industrial vehicles for decades.

2 Why they were popular:

- Low upfront cost

- Mature technology

- Easy to source globally

3 Key limitations in AMR/AGV use:

- Heavy and bulky

- Long charging times

- Cannot handle frequent partial charging well

- Require regular maintenance (especially flooded types)

Lead-acid batteries work best when fully charged, fully discharged, and carefully maintained—conditions that don’t always match modern automated warehouses.

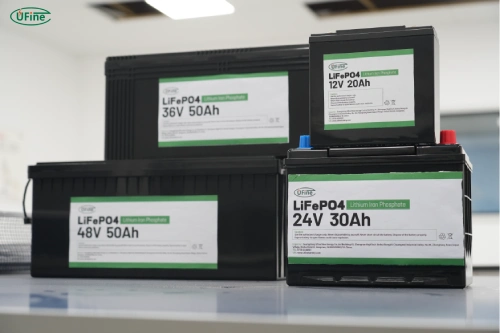

4 Lithium-Ion Batteries (LFP, NMC)

Lithium-ion batteries—especially LFP (LiFePO₄)—are now the dominant choice for AMRs.

5 Why AMR manufacturers prefer them:

- High energy density

- Fast charging

- Long cycle life

- Maintenance-free

- Built-in Battery Management System (BMS)

The BMS continuously monitors voltage, temperature, current, and state of charge, which is critical for robots operating autonomously around people and inventory.

Part 3. Side-by-side comparison: lithium-ion vs lead-acid

| Factor | Lithium-Ion | Lead-Acid |

|---|---|---|

| Energy Density | High | Low |

| Weight & Size | Compact, lightweight | Large, heavy |

| Charging Time | 1–2 hours | 6–10 hours |

| Opportunity Charging | Fully supported | Not recommended |

| Cycle Life | 2,000–5,000 cycles | 500–1,000 cycles |

| Maintenance | None | Regular inspection |

| Safety Control | Advanced BMS | Limited |

| Downtime Impact | Minimal | High |

| Installation Flexibility | High | Limited |

Tip: If you want a deeper dive into AMR battery life comparisons, check out Humanoid Robot Battery Life—many principles apply to AMR systems too.

Part 4. Runtime & charging strategy comparison

Battery choice directly shapes how your fleet operates.

With lead-acid batteries, robots typically:

- Run one full shift

- Stop for long charging sessions

- Require spare batteries or robots to maintain throughput

With lithium-ion batteries, robots can:

- Charge during short idle windows

- Share fast chargers

- Operate across multiple shifts without battery swaps

Scenario Tip: For high-throughput warehouses, lithium-ion enables continuous operation, not just longer runtime.

Part 5. Total cost of ownership (TCO): The real cost over time

Lead-acid batteries look cheaper upfront—but that’s only part of the story.

Key hidden costs of lead-acid:

- More frequent replacements

- Labor for maintenance

- Dedicated charging rooms

- Downtime during long charging cycles

Lithium-ion batteries cost more upfront, but:

- Last 2–4× longer

- Reduce labor costs

- Improve fleet utilization

- Lower downtime-related losses

Example TCO Comparison (3–5 years)

| Battery | Initial Cost | Maintenance | Downtime Loss | Total 5yr Cost |

|---|---|---|---|---|

| Lithium-Ion | $2000 | $100 | $50 | $2150 |

| Lead-Acid | $1200 | $300 | $200 | $1700 |

Tip: Always consider the total cost of ownership, not just upfront purchase price. Sometimes spending more upfront saves far more in operational efficiency.

Part 6. Safety & compliance in industrial environments

Safety matters more in automated environments where robots operate near people.

1 Lead-acid risks::

- Acid leakage

- Gas emissions during charging

- Ventilation requirements

2 Lithium-ion risks::

- Thermal runaway (rare, but serious)

To learn more about preventing thermal runaway in LiFePO₄ batteries, check out this detailed guide on causes, hazards, and solutions.

Why LiFePO4 Thermal Runaway: Causes, Hazards, Solutions

Modern AMR lithium batteries focus heavily on:

- Fire-resistant cell chemistry (LFP)

- Multi-layer BMS protection

- Thermal monitoring and fault isolation

Common Standards: UN38.3, IEC certifications, and internal warehouse fire safety codes.

Pro Tip: When installing lithium-ion batteries, always follow the manufacturer’s safety and storage guidelines. Properly designed lithium systems are as safe—or safer—than lead-acid setups.

Part 7. Operational maintenance & troubleshooting

Even lithium-ion batteries need some care. Here’s a quick checklist:

| Issue | Possible Cause | Solution |

|---|---|---|

| Short runtime | Old battery, high cycle count | Replace battery |

| Won’t charge | Faulty connector | Check wiring and BMS |

| Overheating | High ambient temperature | Pause operation, ensure ventilation |

| Unexpected shutdown | Deep discharge or software fault | Recalibrate battery / reset robot |

Tip: Regularly inspect connections and keep software/BMS updated to minimize downtime.

Part 8. Decision checklist: which battery should you choose?

Before choosing, ask yourself:

- Do my robots need opportunity charging?

- Are uptime and fleet utilization critical?

- Do I want to reduce maintenance labor?

- Am I planning to scale the fleet?

If most answers are “yes” → Lithium-ion is your best choice.

If mostly “no” → Lead-acid may still work for legacy or low-duty setups.

Part 9. FAQs

1. What maintenance does a lead-acid AMR battery require?

Lead-acid batteries need regular checks of electrolyte levels (for flooded types), cleaning terminals, and ensuring proper ventilation during charging. AGM and gel types require less, but still need periodic inspection and equalization charges to maintain capacity.

2. How does temperature affect AMR battery performance?

Extreme temperatures reduce battery efficiency. Cold slows chemical reactions, shortening runtime, while heat accelerates degradation. Lithium-ion batteries handle moderate ranges better than lead-acid, but both should be stored and operated within manufacturer-recommended temperatures.

3. Are Li-ion batteries compatible with AGV battery swapping systems?

Yes, many modern Li-ion batteries are designed for swapping systems, especially in AGVs. Ensure the battery pack size, voltage, and connectors match the robot’s swapping station specifications to avoid compatibility issues.

4. What is the typical charging time for each battery type?

Lithium-ion AMR/AGV batteries usually charge in 1–2 hours, while lead-acid batteries take much longer—typically 6–10 hours for a full charge. Fast or opportunity charging works best with lithium-ion technology.

5. How often should lead-acid batteries be serviced?

Flooded lead-acid batteries should be checked weekly for electrolyte levels and terminal corrosion. AGM or gel types require monthly inspection. Regular maintenance extends lifespan and prevents sudden failures.

6. Can lithium-ion batteries handle rapid start-stop cycles?

Yes, lithium-ion batteries excel at frequent start-stop cycles, making them ideal for AMRs and AGVs with dynamic navigation. Lead-acid batteries, in contrast, degrade faster under the same conditions.

7. What happens if a battery overheats during operation?

Overheating can trigger protective systems in lithium-ion batteries or cause accelerated degradation in lead-acid. In severe cases, it may lead to thermal runaway (Li-ion) or electrolyte loss (lead-acid). Always ensure proper cooling and monitoring.

8. How do I know when a battery needs replacement?

Signs include significantly reduced runtime, failure to hold full charge, frequent alarms, swelling (Li-ion), or leakage (lead-acid). Monitoring software or BMS reports can provide early warnings before complete failure.

Related Tags:

More Articles

고방전 배터리는 높은 전류와 발열로 배터리수명이 줄어듭니다. 구조적 한계, 사용 패턴, 충전 습관 등 실제 수명 단축 요인을 체계적으로 분석했습니다.

Capacitor vs Battery: What is the Difference?

Capacitor vs battery explained in detail. Learn the difference between capacitor and battery in energy storage, charging speed, lifespan, and real applications.

18650 Battery vs AA: Which Is Better for Your Device?

Compare 18650 vs AA batteries in capacity, voltage, rechargeability, and applications. Learn which battery type fits high-drain or everyday devices.

What is the Difference Between Battery Cell, Battery Control Module, and Battery Pack?

Compare battery cells, modules, and packs. Learn functions, design differences, control modules, and selection tips for EV, ESS, and industrial use.

How to Prevent LiPo Battery Explosion?

Can LiPo batteries explode or catch fire? Learn key causes of LiPo battery fires and proven charging, storage, and handling tips to reduce explosion risk.