- Part 1. What are battery monitors?

- Part 2. How a battery monitor works

- Part 3. Types of battery monitors

- Part 4. Do you need a battery monitor?

- Part 5. Advantages of having a battery monitor

- Part 6. Disadvantages and limitations

- Part 7. How to choose the right battery monitor

- Part 8. How to check if you already have a battery monitor

- Part 9. Installing or setting up a battery monitor

- Part10. Common issues with battery monitors

- Part 11. Maintaining and calibrating your battery monitor

- Part 12. FAQ

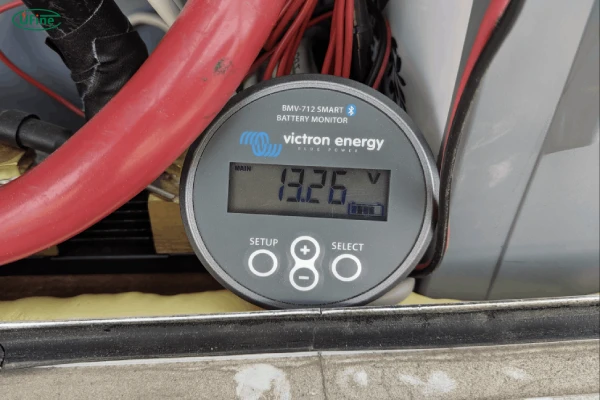

Part 1. What are battery monitors?

Define the term clearly up front:

A battery monitor—often called a battery meter or battery gauge—is effectively a fuel gauge for a battery or battery bank. It displays real-time information like state of charge (SOC), remaining capacity, voltage, current (amps), power (watts), and sometimes time-to-empty/time-to-full.

Avoid confusion: “monitor battery” (search phrase) often means battery monitor (the device), not a battery inside a display or a monitor powered by batteries.

Why it matters across many contexts:

Any system that relies on stored energy benefits from knowing how much energy remains, how fast it’s being used, and whether charging/discharging stays within safe limits.

Representative (not exclusive) application categories:

- Consumer mobility & micromobility: e-bikes, e-scooters, wheelchairs, golf carts.

- Aerial & robotics: drones/UAVs, AGVs/AMRs, service robots.

- Automotive & transport: passenger EVs, motorcycles, powersports, marine, specialty vehicles, forklifts.

- Tools & equipment: power tools, portable test gear, film/photography rigs.

- Stationary energy storage: home batteries, solar + storage, microgrids, community ESS.

- Critical power & telecom: UPS/data centers, telecom base stations, remote monitoring huts.

- Medical & laboratory: portable medical devices and carts, field diagnostics.

- Recreation & outdoors: portable power stations, camping setups.

Part 2. How a battery monitor works

Core measurements:

- Voltage (V): Snapshot health indicator; alone it’s a weak proxy for SOC—varies with load/temperature/chemistry.

- Current (A): Real-time charge/discharge rate; positive when charging, negative when discharging.

- Power (W): Derived from V × A; helpful for understanding load/charging power.

- Temperature (optional): Used by advanced monitors for accuracy and safety margins.

Coulomb (amp-hour) counting:

A shunt-based monitor measures current flowing in/out and integrates over time to estimate SOC and remaining Ah/Wh.

Requires accurate battery capacity settings and efficiency factors; drift occurs without periodic synchronization (full charge events).

Shunt resistor & sense circuitry:

A precision shunt (very low resistance) is installed in series (usually on the negative leg) to create a tiny, measurable voltage drop proportional to current.

The monitor samples this drop with high-resolution ADCs, applies calibration constants, and computes current.

Algorithms & corrections:

Peukert effect (lead-acid), charge acceptance, chemistry profiles (LFP vs NMC vs lead-acid), and temperature compensation improve estimates.

State of health (SOH) trends may be inferred over time via capacity fade tracking (advanced models).

Why simple voltmeters aren’t enough:

Under load, voltage sags; at rest, it rebounds. Without current/time context, voltage-only gives misleading SOC—especially for lithium chemistries with flat voltage curves.

Data outputs & presentation:

On-device display, LED/LCD panels, mobile apps (Bluetooth/Wi-Fi), web dashboards, CAN/Modbus/RS-485 for BMS/EMS/SCADA integration.

Alarms & relays to trigger loads, contactors, or generator/charger start.

Part 3. Types of battery monitors

1.Voltage-only meters (basic):

Lowest cost; display voltage and sometimes a simple bar graph.

Adequate for quick checks, but unreliable for accurate SOC.

Shunt-based SOC monitors (most common for accuracy):

Provide voltage, current, SOC, energy in/out, historical logs.

Variants with programmable alarms, relay outputs, temp sensing.

2. Smart/Bluetooth/Wi-Fi monitors:

Companion apps, data logging, firmware updates, cloud dashboards, CSV export.

Useful for fleets, remote sites, and performance analysis.

3. BMS-integrated monitors:

Many lithium packs have an internal Battery Management System that provides SOC; external monitors can augment or bridge to user interfaces/SCADA.

Battery State of Charge and Battery State of Health

Note integration options: CAN bus, Modbus, open APIs.

4. Panel-mounted vs. inline vs. DIN-rail:

Choose form factor based on environment: vehicles, equipment panels, lab benches, control cabinets.

Multi-channel & high-current models:

For large ESS, forklifts, telecom, data centers; look for 500A/1000A shunts or Hall-effect sensors where isolation is needed.

5. Specialized monitors:

High-voltage packs (EV modules/ESS strings), medical-grade, marine-rated (IP67/IP68), intrinsically safe (ATEX/IECEx) for hazardous locations.

Part 4. Do you need a battery monitor?

General rule: If runtime, longevity, safety, or reliability matter, a monitor is valuable.

Where it’s essential or strongly recommended:

- Stationary storage & microgrids: Predictable SOC avoids unexpected outages, optimizes charge windows (TOU tariffs), and protects depth of discharge.

- Critical power / UPS / telecom: Ensures backup readiness; logs discharge events for compliance and audits.

- Mobility & fleet: E-bikes, scooters, forklifts, AGVs—SOC visibility reduces downtime, schedules charging, and prevents hard cutoffs.

- Drones & film gear: Accurate time-remaining is crucial to avoid mid-air or mid-shot shutdowns.

- Medical & mission-critical: Visibility and alarms support patient safety and continuity of care (subject to device regulations).

- Industrial & construction tools: Prevents battery abuse, supports rotation and charging policy.

When a basic solution may suffice:

- Simple standby batteries seldom used; non-critical gadgets where a rough voltage check is “good enough.”

- Single-cell or very small packs with predictable usage and built-in indicators.

Decision factors:

Battery value (cost of replacement), downtime cost, safety/regulatory needs, need for logs/telemetry, chemistry sensitivity (e.g., lead-acid’s cycle life vs DOD, lithium’s flat voltage curve).

Part 5. Advantages of having a battery monitor

1. Accurate State of Charge:

Avoids over-discharge (which shortens life or triggers BMS cutoffs) and avoids shallow, frequent top-offs that may be inefficient.

Time-to-empty/time-to-full helps plan workflows and trips.

2. Longer Battery Life & Lower TCO:

Proper SOC windows (e.g., 20–80% for some lithium use cases) reduce stress and extend cycle life.

Charge efficiency tracking can expose poor chargers or wiring drops.

3. Operational Reliability:

Alerts/relays can shed non-critical loads or auto-start generators/chargers.

Event logs support warranty claims, root-cause analysis, compliance.

4. Energy Optimization:

Match loads to available capacity; schedule energy-intensive tasks with adequate SOC or cheap grid windows.

5. Fleet & Remote Management:

Cloud dashboards centralize SOC across assets; predictive maintenance from trend data (capacity fade, rising internal resistance if available).

6. User Confidence & Safety:

Fewer surprises; better risk management in critical environments.

Part 6. Disadvantages and limitations

Cost & Complexity:

Shunt monitors add hardware, wiring, and setup; high-current systems need robust components.

Calibration & Drift:

SOC accuracy depends on correct battery capacity, chemistry settings, and full-charge synchronization. Without these, readings drift.

Installation risk if done poorly:

Incorrect shunt placement, loose connections, or undersized cables can cause heat, noise, or measurement errors.

Environmental constraints:

Temperature, moisture, vibration; need IP-rated or ruggedized devices where appropriate.

Data Overload / Integration Effort:

Telemetry is only useful if someone reviews it or if alerts are well-tuned.

Part 7. How to choose the right battery monitor

Chemistry compatibility:

Lead-acid (flooded/AGM/gel) needs Peukert and temperature compensation; lithium (LFP/NMC/NCA) benefits from flat-curve SOC models; nickel chemistries have different voltage profiles.

Battery bank size & current:

Choose shunt rating (e.g., 100A/200A/500A/1000A) with headroom; consider continuous vs. surge loads (inverters, motors).

Accuracy & resolution:

ADC bit-depth, current resolution at low loads, zero-offset stability; look for calibration procedures and temp compensation.

Display & UX:

Local readout (LCD/OLED), brightness, multilingual UI, touch buttons, audible alarms; app/web options if needed.

Connectivity & protocols:

Bluetooth/Wi-Fi for consumer convenience; CAN, RS-485/Modbus, Ethernet for industrial/ESS; API access for dashboards.

Features & expandability:

Data logging, CSV export, firmware updates, relay outputs, multi-bank monitoring, aux temp sensors.

Mechanical & environmental:

Panel mount vs. inline vs. DIN-rail; enclosure ratings (IP65+), vibration resistance, operating temperature range.

Regulatory & safety:

Look for relevant marks (UL/CE/IEC), medical or marine ratings if applicable, EMC compliance.

Vendor support & ecosystem:

Documentation, app quality, firmware cadence, integration guides, community/installer base.

Budget tiers & tradeoffs:

- Entry-level voltage-only → low cost, low accuracy.

- Mid-range shunt monitors → good accuracy/features for most users.

- Pro/industrial → advanced I/O, high current, ruggedness, integration.

Part 8. How to check if you already have a battery monitor

Look at the interface:

If you only see voltage and maybe a bar icon, it’s likely not a true SOC monitor.

If you see amps in/out, amp-hours, watt-hours, SOC %, time-remaining, you likely have a proper monitor or BMS display.

Inspect the battery wiring:

A shunt block in the negative path is a strong indicator of a shunt-based system.

For lithium packs, an onboard BMS may provide SOC via app/CAN—even if no external shunt is visible.

Check documentation:

Device manuals, system one-lines, wiring diagrams, or app screenshots usually reveal monitoring capabilities and protocols.

Look for companion apps or dashboards:

Search by brand/model; often there’s an app or web portal if the device supports telemetry.

Part 9. Installing or setting up a battery monitor

Safety first:

De-energize circuits; remove jewelry; wear PPE; follow lock-out/tag-out where applicable. High-current DC can arc.

Shunt placement best practices:

- Install the shunt as the single return path for all loads/chargers (except safety grounds). Everything must go through the shunt to be measured.

- Keep cable runs short; torque lugs to spec; use proper gauge and crimping tools.

- Avoid parallel return paths that bypass the shunt (creates SOC errors).

Wiring & noise considerations:

- Route sense leads away from high-EMI sources; twist pairs where recommended; add ferrites if specified.

- Ensure a solid low-resistance connection; clean oxidation on lugs/busbars.

Commissioning / initial configuration:

- Enter battery chemistry, rated capacity (Ah/Wh), charged-voltage threshold, tail-current, charge efficiency.

- Perform a full charge to 100% and synchronize SOC.

- Verify idle current is near zero and adjust zero-offset if the device supports it.

Mounting & environmental:

Keep displays accessible; protect from moisture/heat/vibration per spec; consider IP-rated enclosures if necessary.

Documentation:

Label wiring, save screenshots of settings, and store a commissioning checklist for future maintenance.

Part10. Common issues with battery monitors

SOC inaccuracy/drift:

- Causes: wrong capacity, aging battery (true capacity lower), missing full-charge events, shunt bypass paths, temp effects.

- Fixes: update capacity after capacity test; enforce periodic 100% charges; reroute wiring; enable temperature compensation.

Noisy or fluctuating readings:

- Causes: poor connections, EMI from inverters/motors, shared grounds.

- Fixes: re-crimp/retorque lugs; improve cable routing; add ferrites; check shield/grounding scheme.

Zero-current offset:

- Symptom: device shows phantom +/- amps at rest → SOC drifts over time.

- Fix: perform zero-cal at true no-load/no-charge condition; verify firmware.

Connectivity/app problems:

- Bluetooth dropouts, Wi-Fi AP isolation, firewall blocks for cloud.

- Fixes: firmware updates, closer mounting, external antennas, documented port rules.

Environmental failures:

- Condensation, salt spray, vibration loosening fasteners.

- Fixes: IP-rated gear, conformal coatings, thread-lockers, inspection intervals.

Part 11. Maintaining and calibrating your battery monitor

Routine checks:

- Inspect terminations quarterly; check for heat discoloration; verify torque.

- Review logs for unusual discharge peaks or chronic deep cycles.

Periodic synchronization:

- Schedule full charges (per chemistry guidance) so the monitor can relearn 100% SOC; set “charged detection” thresholds correctly (voltage + tail current + time).

- For lead-acid, include absorption/float as required; for lithium, avoid excessive time at 100% if not needed operationally—balance with accuracy needs.

Re-rating capacity over life:

- Perform an occasional controlled discharge test to estimate real capacity; update the monitor so SOC tracks reality.

- Note cycle count and temperature history to contextualize capacity fade.

Firmware & app updates:

Apply updates for bug fixes, accuracy improvements, new features, and security patches.

Record-keeping:

Keep a maintenance log (dates, settings, firmware versions, capacity tests). Useful for audits, warranty, and fleet optimization.

Part 12. FAQ

Is a battery monitor the same as a voltmeter?

No. A voltmeter shows electrical pressure at an instant; a battery monitor also measures current and tracks energy in/out to estimate state of charge and time-remaining, which voltage alone cannot do reliably—especially with lithium chemistries.

Do I need a shunt for accurate SOC?

In most cases, yes. Shunt-based monitors measure current precisely, enabling accurate coulomb counting. Some systems rely on a BMS’s internal measurements via digital bus; accuracy depends on the BMS quality and calibration.

Will a battery monitor work with any chemistry (lead-acid, LFP, NMC, etc.)?

Generally yes, but you must configure the chemistry profile, capacity, and detection thresholds. Some monitors offer specific profiles for improved accuracy.

How accurate are battery monitors?

Accuracy varies by device and setup. With proper shunt installation, configuration, temperature compensation, and periodic synchronization, many achieve very good practical accuracy for operational decisions.

Can a monitor extend battery life?

Indirectly, yes. By keeping you informed, it helps avoid deep discharges, manage charge windows, and spot issues (bad chargers, parasitic loads) that would otherwise reduce cycle life.

What size (amp rating) shunt do I need?

Choose a shunt with continuous current headroom above your typical max load, and consider surges from inverters or motors. Overspec slightly for reduced heating and better longevity.

What if my SOC jumps after power cycles or app reconnects?

That’s often a sign of poor synchronization, zero-offset drift, or incorrect charged detection. Re-sync after a verified full charge, recalibrate zero-current, and confirm settings.

Can I integrate the monitor into my existing control system?

Many support CAN, RS-485/Modbus, Ethernet, or APIs. Check protocol support and data points (SOC, current, voltage, alarms) for compatibility with your BMS/EMS/SCADA.

Related Tags:

More Articles

A Complete Guide to the Best Batteries for Flashlights

Compare the best batteries for flashlights, including AA, AAA, 18650, 21700, CR123A. See which battery offers the best brightness, runtime, and reliability.

How Long Do Rechargeable AA Batteries Last?

How long do rechargeable AA batteries last? Compare NiMH and lithium AA lifespan, recharge cycles, key factors, and performance vs alkaline batteries.

How Much Current Can a 9V Battery Really Supply?

Discover how many amps a 9V battery can supply, its actual current output, discharge rate, and capacity for alkaline, lithium, and rechargeable 9V batteries.

12V STD vs 12V AGM: Meaning, Differences, and Which Is Better

Understand what STD and AGM batteries mean, their key differences, and which 12V battery fits your needs best in 2026.

Battery Reconditioning Explained: A Comprehensive Guide

Learn what battery reconditioning is, how it works, how long it takes, and when reconditioning chargers are used for lead-acid and lithium-ion batteries.