- Part 1. What is a battery load test?

- Part 2. Principles of battery load testing

- Part 3. Types of battery load tests

- Part 4. Battery load testing equipment

- Part 5. Battery load testing procedure

- Part 6. Interpreting load test results

- Part 7. 5 Critical Battery Load Test Mistakes

- Part 8. FAQs about Battery Load Testing

- Part 9. Conclusion

A battery load test is a diagnostic method to measure a battery’s ability to deliver power under controlled conditions. It shows real performance under stress, helping identify weak batteries before failure. Applications include car battery load testing, solar energy systems, and industrial equipment.

Modern devices from smartphones and laptops to cars and industrial machinery rely on batteries. Over time, batteries may lose capacity, causing operational issues. Battery load testing provides a reliable method to assess battery health and performance.

Part 1. What is a battery load test?

Battery load testing is a diagnostic procedure used to measure a battery’s performance and health by applying a controlled load. It determines the battery’s ability to deliver power and maintain voltage levels under real-world conditions, helping prevent unexpected failures.

Importance of Battery Load Testing

- Ensuring Performance: Evaluate battery performance under stress and identify degradation.

- Preventing Failures: Detect weak batteries early to reduce downtime and repair costs.

- Extending Lifespan: Optimize charge/discharge cycles and maintenance for longer battery life.

- Safety: Identify potential risks in automotive, solar, and industrial applications.

Part 2. Principles of battery load testing

Understanding the principles of load testing ensures accurate results and reliable battery assessment.

Load Testing Methodology

- Fully charge the battery and ensure recommended temperature.

- Connect to load testing equipment.

- Apply a controlled load for a specified duration.

- Monitor voltage and performance during the test.

- Analyze results to determine battery condition.

Factors Affecting Load Testing

- Battery Temperature: Conduct tests at recommended temperatures for consistent results.

- Load Applied: Use appropriate load levels reflecting real-world usage.

- Test Duration: Follow battery specifications; too short or long tests can misrepresent health.

- Equipment Calibration: Ensure testers are calibrated for accurate measurements.

Part 3. Types of battery load tests

Common types of load tests:

- Constant Current Load Test: Apply constant current, measure voltage over time, assess sustained performance.

- Pulse Load Test: Apply high-current pulses to simulate sudden demand; evaluates peak load handling.

- Capacity Load Test: Discharge battery at a set rate until predefined voltage; assesses usable capacity.

- Cranking Load Test: Automotive test for high current delivery during engine start.

- Car Battery Load Test: Measure Cold Cranking Amps (CCA) with 15-second cycles.

- Solar Battery Load Test: Use 20-hour capacity rating (C20) for deep-cycle evaluation.

Part 4. Battery load testing equipment

Using the right equipment ensures accurate battery load testing results.

| Equipment Type | Recommended Models | Best For | Price Range |

|---|---|---|---|

| Digital Load Tester | Midtronics MDX-650 | Automotive Batteries | $300-$400 |

| Industrial Analyzer | Fluke 500 Series | Solar/Deep Cycle Batteries | $450-$600 |

| Basic Multimeter | INNOVA 3320 | Quick Voltage Checks | $20-$50 |

Key Equipment and Functions

- Load Tester: Applies controlled load, measures voltage response, current, and internal resistance.

- Multimeter: Measures voltage, current, resistance during load test for additional diagnostics.

- Data Logger: Records voltage/current trends during testing for performance analysis.

- Safety Equipment: Gloves, goggles, and protective clothing to prevent accidents.

Part 5. Battery load testing procedure

How to load test a battery safely?

- Preparation:

- Charge lead-acid to 12.6V or lithium to 3.65V per cell.

- Wear ANSI-approved gloves & goggles.

- Connection:

- Attach red clamp to (+), black to (-).

- Ensure contacts are clean and corrosion-free for accurate readings.

- Load Application:

- Automotive batteries: Apply 50% CCA for 15 seconds to evaluate starting power.

- Deep-cycle batteries: Apply 3x Ah rating for 3 hours to assess usable capacity.

- Voltage Monitoring:

- Record initial, 5s, and 15s voltage readings.

- Stop the test if voltage drops below 9V for a 12V battery.

This structured approach ensures accurate load test battery results for various applications.

Part 6. Interpreting load test results

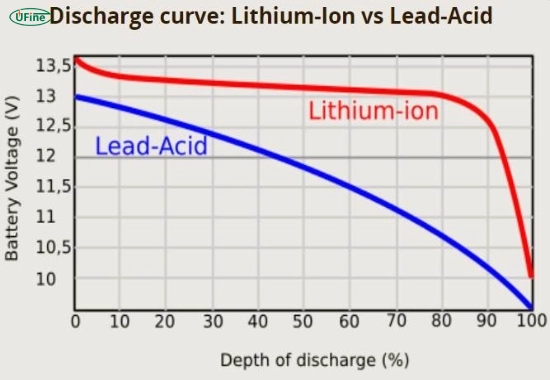

Analyzing battery load test chart and voltage response helps determine battery health.

Voltage Response

A healthy battery maintains stable voltage under load. Significant drops indicate capacity loss or high internal resistance.

Capacity Assessment

Compare observed capacity with rated capacity. Low results suggest aging or degradation.

Performance Analysis

Check for inability to sustain load or irregular voltage patterns. These highlight potential operational risks.

Trends and Historical Data

Compare with previous load tests to detect progressive degradation or improvements.

Battery Load Test Voltage Chart

- 12V Automotive: ≥9.6V @ 15s load → Healthy

- 6V Golf Cart: ≥5.5V @ 30min → Replace if below

- Solar Lithium: ≤3% voltage drop @ 1C rate → Acceptable

Use this chart as a quick reference for evaluating test outcomes. Proper interpretation ensures timely maintenance and prevents unexpected battery failures.

Part 7. 5 Critical Battery Load Test Mistakes

❌ Testing a Discharged Battery

Charging to full state-of-charge (SOC) is essential. Testing a discharged battery gives false “bad battery” results.

❌ Ignoring Temperature Compensation

Voltage readings change with temperature. Add 0.01V/°F above 80°F, subtract below (per SAE J537) for accuracy.

❌ Using Wrong Load Settings

Automotive: 50% CCA. Deep-cycle: 3x Ah. Incorrect loads can misrepresent performance.

❌ Testing Immediately After Charging

Wait 2 hours for surface charge to dissipate. Testing too soon gives inflated voltage readings.

❌ Using Damaged Cables

Worn clamps increase resistance >0.2Ω, causing voltage drop errors. Replace cables for reliable results.

Part 8. FAQs about Battery Load Testing

How long does a battery load test take?

Automotive: 15-30 seconds. Deep-cycle/solar: 1-3 hours. Duration depends on battery type and load.

Can you load test a lithium battery?

Yes, use CC/CV mode ≤1C rate. Avoid traditional resistive loads to prevent damage.

Is a load test better than a voltage test?

Yes. Voltage only shows surface charge; load test reveals actual performance under stress.

Can I do a load test without special equipment?

Basic tests can use headlights (auto) or inverters (solar), but professional tools give precise results.

How often should load testing be done?

Critical systems: every 6 months. Automotive batteries: annually.

Part 9. Conclusion

Battery load testing is crucial for evaluating performance, preventing unexpected failures, and extending battery life. By following the principles, choosing the right equipment, and correctly interpreting battery load test chart results, you can maintain reliable power in automotive, solar, and industrial applications.

Regular battery load testing combined with proper maintenance can extend battery life by up to 40%. For deeper optimization, learn more about battery reconditioning to maximize your power solutions.

Related Tags:

More Articles

Capacitor vs Battery: What is the Difference?

Capacitor vs battery explained in detail. Learn the difference between capacitor and battery in energy storage, charging speed, lifespan, and real applications.

18650 Battery vs AA: Which Is Better for Your Device?

Compare 18650 vs AA batteries in capacity, voltage, rechargeability, and applications. Learn which battery type fits high-drain or everyday devices.

What is the Difference Between Battery Cell, Battery Control Module, and Battery Pack?

Compare battery cells, modules, and packs. Learn functions, design differences, control modules, and selection tips for EV, ESS, and industrial use.

How to Prevent LiPo Battery Explosion?

Can LiPo batteries explode or catch fire? Learn key causes of LiPo battery fires and proven charging, storage, and handling tips to reduce explosion risk.

Aluminium Ion Battery vs Lithium-Ion: A Detailed Comparison

Compare aluminium ion battery vs lithium-ion battery in energy density, charging speed, safety, cost, and uses. A practical guide for engineers and buyers.