- Part 1. Industry challenges: Why power tool batteries are unique

- Part 2. Our power tool battery solution overview

- Part 3. Why 18650 batteries are widely used in power tools

- Part 4. What defines the best 18650 battery for power tools

- Part 5. Recommended battery chemistries & configurations by tool type

- Part 6. Certifications & compliance

- Part 7. Custom power tool battery

Part 1. Industry challenges: Why power tool batteries are unique

Power tools demand more from batteries than ordinary devices. Unlike consumer electronics, power tools operate under high current loads, frequent charge–discharge cycles, and continuous heavy-duty usage, often generating significant heat. Key challenges include:

- High Discharge Currents – To deliver consistent torque and performance, batteries must sustain large continuous currents without voltage drops.

- Thermal Management – Heat accumulation can reduce cycle life and cause safety issues.

- Long Cycle Life – Tools are expected to last years with minimal battery degradation.

- Compact Design Constraints – Batteries must fit ergonomic handles or portable packs while maintaining energy density.

- Safety & Compliance Requirements – Meeting UN38.3, IEC62133, UL, CE, and other standards is critical for industrial and professional-grade tools.

Understanding these challenges is the first step to selecting or designing the right battery solution.

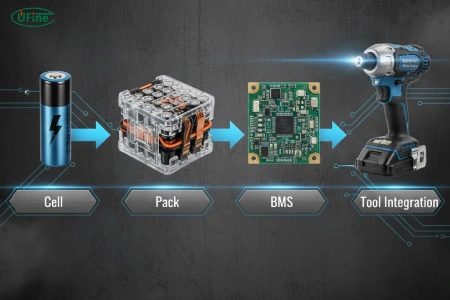

Part 2. Our power tool battery solution overview

Ufine Battery provides a complete power tool battery solution ecosystem, covering cells, packs, and system-level design. Our offerings include:

- High-Performance Lithium-Ion Cells – 18650 and 21700 formats optimized for high-current applications.

- Custom Battery Packs – Configurations in series and parallel for 12V, 18V, and 20V platforms.

- Battery Management Systems (BMS) – Ensuring safe operation, balancing cells, and monitoring performance.

- Thermal and Mechanical Protection – Specialized housing, heat dissipation, and vibration resistance for harsh conditions.

- Scalable Solutions – From prototype development to volume production.

See how Ufine Battery designs and assembles high-performance power tool batteries in our state-of-the-art production facility.

Part 3. Why 18650 batteries are widely used in power tools

18650 lithium-ion cells have become the standard choice for many power tools due to:

- Balanced Energy Density and Power Output – High energy for long runtime while supporting high discharge currents.

- Proven Reliability – Decades of industrial use provide consistent performance and availability.

- Ease of Pack Assembly – Standardized sizes simplify series/parallel configuration and BMS integration.

Expert Insight: Selecting the right 18650 isn’t just about voltage and capacity—it’s about discharge rate, cycle life, and thermal performance under real-world conditions.

Part 4. What defines the best 18650 battery for power tools

Choosing the best 18650 battery requires evaluating multiple technical factors:

- High Continuous Discharge Capability – Ensures consistent torque and performance under load.

- Long Cycle Life – Maintains capacity over thousands of cycles, even under heavy-duty use.

- Low Internal Resistance – Reduces heat generation and improves efficiency.

- Thermal Stability – Prevents overheating during prolonged operation.

- Cell Quality and Matching – Essential for multi-cell packs to avoid imbalance and premature failure.

- Certification & Traceability – Ensures compliance with UN38.3, UL, IEC62133, and CE standards.

Industry Data Insight: Tests show high-rate 18650 cells maintaining 20–25A continuous discharge for over 500 cycles provide optimal performance for most cordless drills and impact drivers.

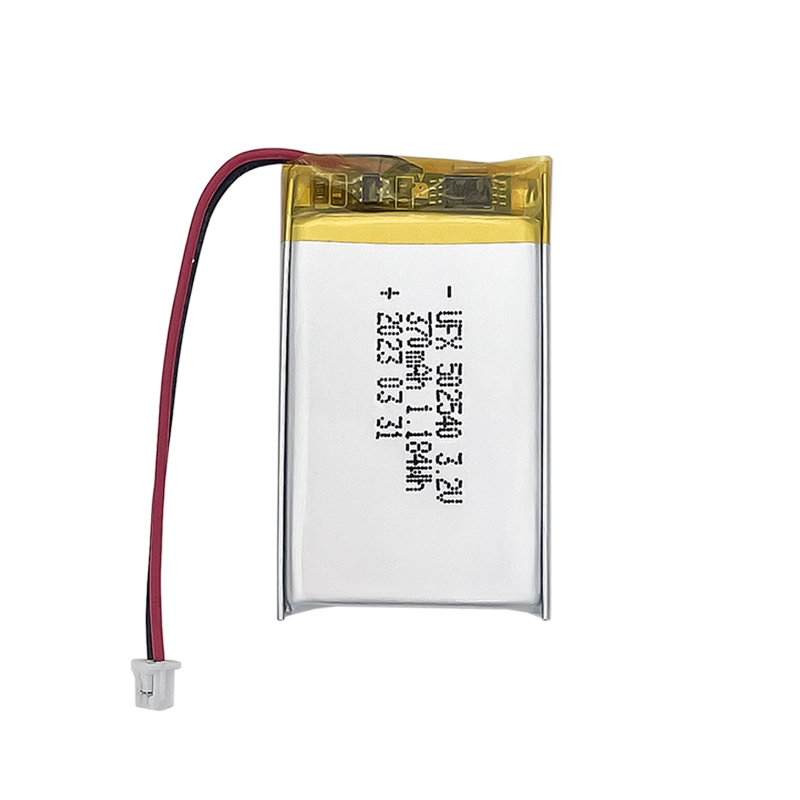

Power tools require batteries that match their energy and power demands. The table below shows a range of high-quality 18650 Li-ion cells we provide, including capacities optimized for different tool types and usage patterns.

| Battery Type | Nominal Capacity | Typical Tool Application | Key Feature |

|---|---|---|---|

| Li-ion 18650 Battery | Standard | Light-duty drills & DIY tools | Reliable, compact |

| 18650 Battery 2000mAh | 2000 mAh | Small drills, mini impact drivers | Lightweight, portable |

| 18650 Battery 2200mAh | 2200 mAh | DIY drills, small saws | Balanced runtime & power |

| 18650 Battery 2600mAh | 2600 mAh | Medium-duty tools | High discharge stability |

| 18650 Battery 3000mAh | 3000 mAh | Professional drills, impact drivers | Long runtime, high current |

| 18650 Battery 3500mAh | 3500 mAh | Heavy-duty tools & industrial use | Maximum capacity, high-rate discharge |

| Other Cylindrical Li-ion Battery | Custom | Special applications | Tailored capacity, voltage, form factor |

Each battery type can be customized further to meet specific tool requirements, including voltage, pack configuration, and discharge rate. Explore the full product range or contact us for custom solutions.

Part 5. Recommended battery chemistries & configurations by tool type

Different power tools require batteries tailored to their usage patterns. Below are commonly used tools and typical battery specifications observed in the industry:

| Tool Type | Typical Voltage | Common Battery Chemistry | Nominal Capacity | Continuous Discharge | Notes |

|---|---|---|---|---|---|

| Cordless Drill | 18V | Li-ion 18650 | 2.0–3.0 Ah | 15–20A | Frequent short bursts of torque |

| Impact Driver | 18V | Li-ion 18650 High-Rate | 2.5–3.5 Ah | 20–25A | High discharge for heavy-duty impact |

| Circular Saw | 20V | Li-ion 21700 | 3.0–4.0 Ah | 25–30A | Long continuous load, thermal stability required |

| Reciprocating Saw | 20V | Li-ion 21700 | 3.5–4.5 Ah | 25–30A | High torque, needs high-rate discharge |

| Jigsaw / Small Tools | 12–18V | Li-ion 18650 | 1.5–2.5 Ah | 10–15A | Lightweight, compact pack preferred |

Pro Tip: These specifications reflect industry-standard choices among professional tool manufacturers and guide pack design for optimal performance.

1 Examples of Tool-Specific Configurations

- High-Rate 18650 Batteries for Impact Drivers – Optimized for 20–25A continuous discharge.

- 21700 Li-ion for Continuous Load Tools – Ideal for circular saws and heavy-duty cutting tools, balancing high capacity and thermal stability.

- Compact 18650 Packs for DIY Tools – Lightweight packs for ergonomic drills and smaller tools.

Part 6. Certifications & compliance

Ufine Battery ensures all power tool batteries meet industry safety and quality standards, including:

- UN38.3 – Safe for transport

- IEC 62133 – Cell and battery safety standards

- UL & CE – Compliance for industrial-grade equipment

- RoHS & MSDS – Environmentally safe materials

These certifications guarantee your tools meet professional and regulatory expectations worldwide.

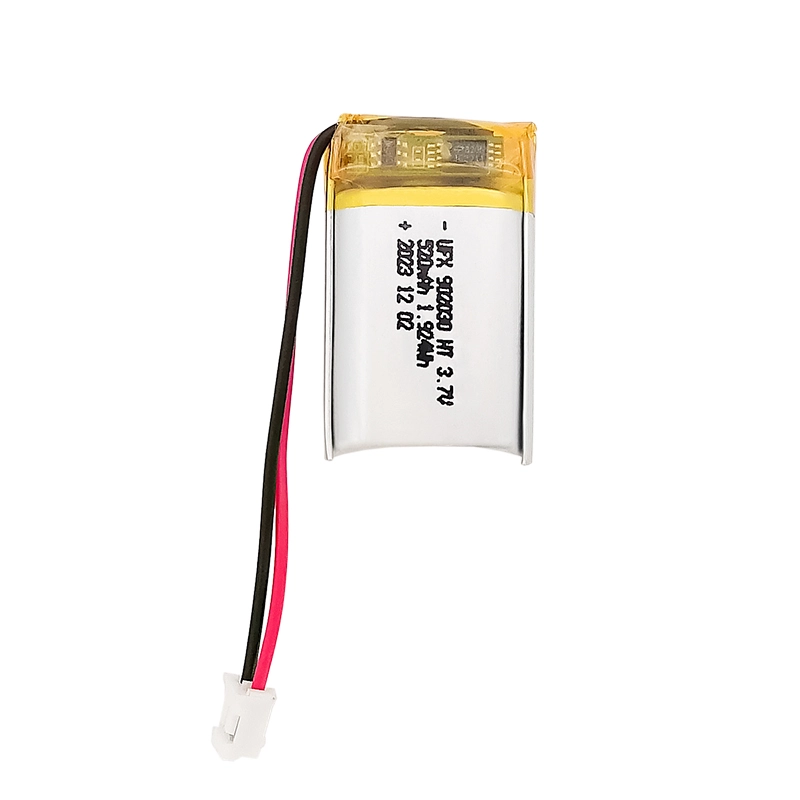

Part 7. Custom power tool battery

We work with OEMs and industrial partners to tailor batteries to your exact requirements, whether you need:

- Specific capacity, voltage, or discharge rate

- Custom cell arrangement, pack shape, or housing

- Integrated BMS and thermal protection

- Prototype to volume production scalability

Ufine Battery can customize capacity, voltage, curvature, and dimensions to meet your specifications — whether for prototype testing or volume production.

Find A Solution NowHigh Energy Density

It stores large amounts of energy in a smaller and lighter package

Longer Cycle Life

Withstands extensive charge and discharge cycles

Low Self-Discharge

Maintains power longer when not in use

Safety

Minimizes the risk of accidents and ensures safe operation

More Information About Power Tool Battery

-

What is the typical lifespan of a power tool battery?

-

How do I choose the right voltage for my power tool battery?

-

Can I mix different battery brands or capacities in the same tool?

-

How does temperature affect power tool battery performance?

-

What maintenance steps improve power tool battery health?

-

How do I know when a power tool battery needs replacement?

Latest Blogs

About Lithium Battery Industry News

Lithium-Ion vs Lead-Acid AMR & AGV Batteries Compared

Discover the pros and cons of lithium-ion and lead-acid AMR & AGV batteries. Learn about cost, lifespan, safety, and which is right for your fleet.

2026/01/14 Ufine

Robot Vacuum Battery Replacement: Easy Step-by-Step Guide

Learn how to replace a robot vacuum battery safely and easily. Step-by-step instructions, battery types, costs, and common mistakes to avoid.

2026/01/14 Ufine

Discover how to choose the right battery for your robot. Compare Li-ion, LiFePO₄, NiMH, and more for performance, safety, and cost.

2026/01/14 Ufine

Inside Humanoid Robot Battery Pack Design

A deep dive into humanoid robot battery pack design, covering battery life, voltage, capacity, safety, and real-world engineering trade-offs.

2026/01/14 Ufine

Humanoid Robot Battery Life: How Long Do They Really Last?

Most humanoid robots run 1.5–4 hours per charge. Learn real-world battery life, battery types, capacity limits, and future improvements.

2026/01/13 Ufine

Battery Load Test: A Comprehensive Guide

Step-by-step battery load test guide for car, solar & industrial use. Learn how to load test a battery, interpret voltage charts, and avoid common mistakes.

2025/12/18 Ufine