- Part 1. Battery requirements in breast pump applications

- Part 2. Common battery-related risks observed in breast pump projects

- Part 3. Typical battery specifications used in breast pumps

- Part 4. Where battery customization is typically required

- Part 5. Battery behavior under real breast pump usage

- Part 6. Ufine R&D and design-in support for breast pump battery projects

- Part 7. Safety & compliance framework for breast pump batteries

- Part 8. Breast pump device types and battery implications

- Part 9. Recommended battery configurations

- Part 10. When to engage battery R&D support

- Part 11. Next step: from requirements to implementation

Breast pump products impose application-specific demands on battery systems that differ from generic consumer electronics.

Successful designs depend not only on nominal capacity, but on discharge stability, thermal behavior, lifecycle performance, and regulatory alignment across the entire product lifecycle.

Part 1. Battery requirements in breast pump applications

Modern breast pumps—particularly portable and wearable models—are predominantly powered by rechargeable lithium batteries, most commonly with a 3.7 V nominal voltage.

Across commercial designs, breast pump batteries are generally expected to meet the following requirements:

- Stable discharge under intermittent motor load

Operation consists of repeated start-stop cycles rather than continuous discharge.

- Low electrical noise characteristics

Voltage ripple and internal resistance directly influence audible motor noise.

- Controlled temperature rise

Devices are used close to the human body, often multiple times per day.

- Compact and lightweight form factor

Enclosure design strongly limits battery thickness and geometry.

- Durable cycle life

Typical targets are ≥500 full cycles, corresponding to 1.5–2 years of daily use.

In breast pump applications, real-world usage behavior has a stronger impact on battery performance than laboratory capacity ratings alone.

Part 2. Common battery-related risks observed in breast pump projects

Industry failure analysis and post-launch feedback frequently point to several recurring battery-related risks:

1 Performance & User Experience Risks

- Voltage sag during motor startup, causing unstable suction

- Audible noise increase over time due to rising internal resistance

- Runtime degradation after repeated short-cycle usage

2 Safety & Thermal Risks

- Excessive surface temperature under frequent operation

- Cell swelling caused by mismatched charge/discharge profiles

- Insufficient protection for close-to-skin usage scenarios

3 Compliance & Project Schedule Risks

- Failure to pass IEC 62133 or UL safety testing

- Late-stage redesign triggered by certification feedback

- Shipping delays caused by incomplete UN38.3 or MSDS documentation

In most cases, these issues are linked to battery configuration and protection design, rather than cell chemistry alone.

Learn practical strategies for preventing lithium polymer battery swelling in our detailed guide: Safety Tips and Solutions to Lithium Polymer Battery Swelling

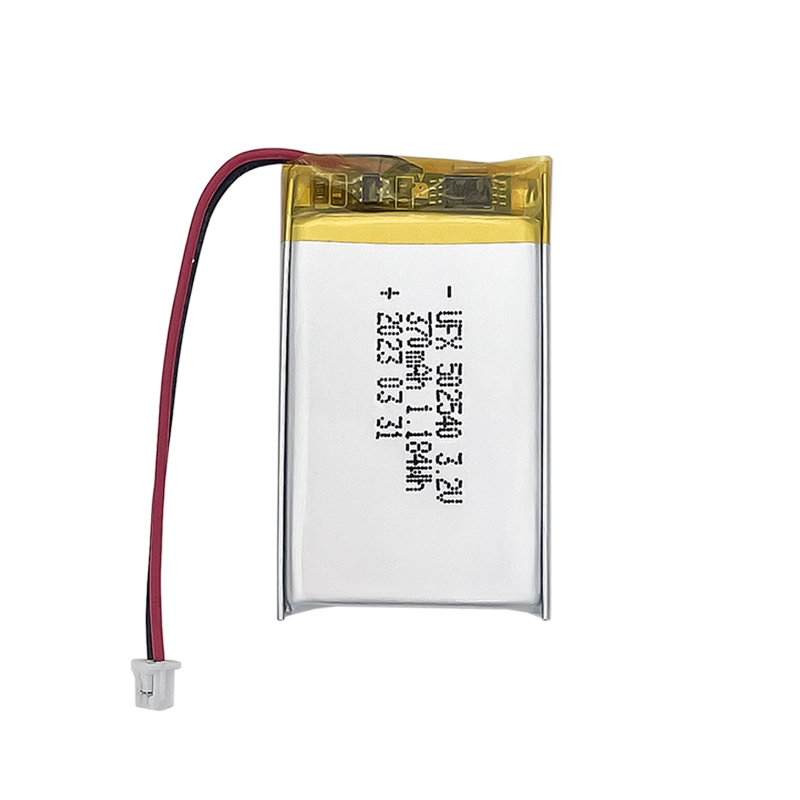

Part 3. Typical battery specifications used in breast pumps

While specifications vary by product class, the following ranges are commonly observed in commercial breast pump designs:

| Parameter | Typical Industry Range |

|---|---|

| Nominal Voltage | 3.7 V |

| Capacity | 1000–3000 mAh |

| Chemistry | Lithium-ion / Lithium-polymer |

| Cycle Life | ≥500 full cycles |

| Discharge Profile | Optimized for intermittent motor load |

| Protection | PCM (over-charge, over-discharge, over-current) |

| Form Factor | Custom pouch or prismatic |

Note: For breast pumps, discharge stability and internal resistance growth often matter more than initial capacity when evaluating long-term performance.

Part 4. Where battery customization is typically required

In breast pump projects, battery customization is often driven by mechanical constraints and real usage patterns, rather than by performance targets alone.

Customization is most commonly required in the following areas:

1 Size & Geometry

- Reduced thickness for wearable and hands-free designs

- Custom outlines to fit compact or curved housings

- Weight optimization for user comfort

2 Capacity & Runtime

- Capacity tuning based on daily usage frequency

- Avoiding oversizing that increases thermal stress

- Balancing charge intervals and battery aging

3 Electrical Characteristics

- Voltage behavior during motor startup

- Protection circuit tuning for frequent short cycles

- Temperature sensing integration (NTC)

Defining these parameters early reduces downstream redesign and certification risk.

Watch how custom battery samples are developed from concept to creation in our video.

Part 5. Battery behavior under real breast pump usage

Breast pumps typically operate in multiple short sessions per day, rather than continuous discharge.

This usage pattern leads to several important implications:

- Cycle aging dominates over calendar aging

- Internal resistance increase has a stronger impact than capacity fade

- Thermal accumulation may occur even at moderate current levels

Design validation should therefore focus on usage-profile-based testing, not capacity benchmarks alone.

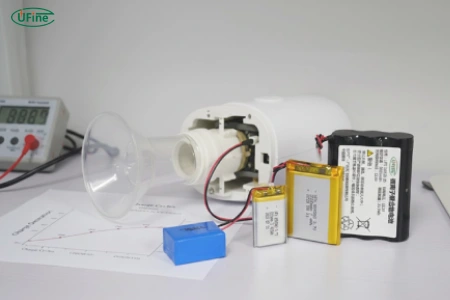

Part 6. Ufine R&D and design-in support for breast pump battery projects

In breast pump development, battery work is rarely a one-step selection process.

Industry practice typically involves multiple design and validation phases before mass production.

We support:

1 Typical Project Stages

Battery R&D support commonly spans:

Concept & requirement definition

– Voltage, capacity, size, target markets, certification scope

Prototype development

– Custom cell configuration and PCM design

– Small-batch sample builds for mechanical and electrical validation

Iterative sample refinement

– Multi-round adjustments based on motor behavior, thermal data, and enclosure feedback

Certification preparation

– Alignment with UN38.3, IEC 62133, and market-specific standards

Pilot build and mass production

– Process validation and batch consistency control

2 Practical Support Capabilities

For breast pump battery projects, effective R&D support typically includes:

- Custom battery design in size, capacity, and voltage

- Low-MOQ prototype sampling for early testing

- Support for multiple sample iterations

- Design alignment for scalable mass production

- Documentation support for certification and logistics

Ufine Battery provides battery R&D and manufacturing support across these stages, enabling both early-stage prototyping and stable volume production.

Work with Ufine Battery for small-batch prototypes, iterative sample refinement, and scalable lithium battery manufacturing.

START YOUR BATTERY PROJECTPart 7. Safety & compliance framework for breast pump batteries

Breast pump batteries generally involve three layers of compliance:

1 Transportation Safety (Global)

- UN 38.3 — Lithium battery transport safety

- MSDS / SDS — Material Safety Data Sheet

2 Battery Safety Standards

- IEC 62133 — International lithium battery safety standard

- UL 2054 / UL 1642 — North American battery safety standards

3 Market-Specific Regulations

| Market | Regulation | Authority |

|---|---|---|

| European Union | CE, RoHS, EU Battery Regulation | https://ec.europa.eu |

| South Korea | KC Certification | https://www.kats.go.kr |

| Japan | PSE (DENAN Law) | https://www.meti.go.jp |

| Global CB Scheme | IECEE CB | https://www.iecee.org |

Certification scope depends on target markets and device classification and should be considered during battery design.

View the full list of battery certifications and compliance standards on our Certification page

Part 8. Breast pump device types and battery implications

Different product categories impose different battery priorities:

Portable breast pumps

→ Balanced size and runtime

Wearable / hands-free breast pumps

→ Ultra-slim geometry and thermal control

Hospital-grade systems

→ Higher durability and long-cycle stability

Battery design choices should align with the intended use scenario.

Part 9. Recommended battery configurations

Below are example battery configurations commonly used as starting points.

All parameters can be adjusted based on project requirements.

| Application Type | Nominal Voltage | Capacity Range | Form Factor | Notes |

|---|---|---|---|---|

| Portable pump | 3.7 V | 1200–2000 mAh | Pouch | Balanced size & runtime |

| Wearable pump | 3.7 V | 1000–1800 mAh | Ultra-slim pouch | Thickness-optimized |

| Hospital-grade | 3.7 V | 2000–3000 mAh | Custom pack | Higher cycle durability |

Part 10. When to engage battery R&D support

Battery R&D involvement is typically recommended when:

- Enclosure space is tightly constrained

- Multiple regional certifications are required

- Long-term reliability is critical

- Pilot builds or small-batch sampling are needed

Early collaboration reduces redesign risk and shortens time to mass production.

Part 11. Next step: from requirements to implementation

If you are defining or reviewing a breast pump battery design, the next practical step is to translate application requirements into a manufacturable battery configuration.

You may prepare:

- Target voltage and capacity

- Size constraints

- Intended markets and certifications

- Estimated usage profile

Request battery R&D support for your breast pump project

Small-batch prototyping, iterative sample adjustment, and mass-production-ready designs can be supported based on your requirements.

High Energy Density

It stores large amounts of energy in a smaller and lighter package

Longer Cycle Life

Withstands extensive charge and discharge cycles

Low Self-Discharge

Maintains power longer when not in use

Safety

Minimizes the risk of accidents and ensures safe operation

More Information About Breast Pump Battery

it.

-

How is a battery breast pump optimized for quiet operation?

-

Can I use a standard lithium battery pack in my breast pump?

-

What safety features are important in a battery operated breast pump?

-

How do I know if a breast pump with rechargeable battery is compatible with travel or transport regulations?

-

What factors influence the runtime of a battery powered breast pump?

Latest Blogs

About Lithium Battery Industry News

Lithium-Ion vs Lead-Acid AMR & AGV Batteries Compared

Discover the pros and cons of lithium-ion and lead-acid AMR & AGV batteries. Learn about cost, lifespan, safety, and which is right for your fleet.

2026/01/14 Ufine

Robot Vacuum Battery Replacement: Easy Step-by-Step Guide

Learn how to replace a robot vacuum battery safely and easily. Step-by-step instructions, battery types, costs, and common mistakes to avoid.

2026/01/14 Ufine

Discover how to choose the right battery for your robot. Compare Li-ion, LiFePO₄, NiMH, and more for performance, safety, and cost.

2026/01/14 Ufine

Inside Humanoid Robot Battery Pack Design

A deep dive into humanoid robot battery pack design, covering battery life, voltage, capacity, safety, and real-world engineering trade-offs.

2026/01/14 Ufine

Humanoid Robot Battery Life: How Long Do They Really Last?

Most humanoid robots run 1.5–4 hours per charge. Learn real-world battery life, battery types, capacity limits, and future improvements.

2026/01/13 Ufine

Battery Load Test: A Comprehensive Guide

Step-by-step battery load test guide for car, solar & industrial use. Learn how to load test a battery, interpret voltage charts, and avoid common mistakes.

2025/12/18 Ufine