- Key Takeaways

- Part 1. How a 24V power supply works?

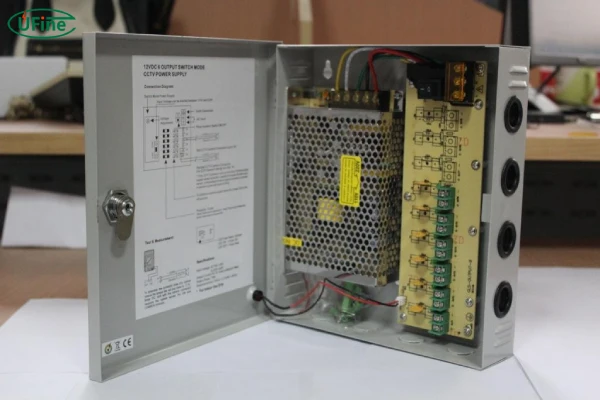

- Part 2. Types of 24V power supplies?

- Part 3. Key parameters of a 24V power supply

- Part 4. How to choose the right 24V power supply?

- Part 5. 24v Power supply vs. 12v power supply: what’s the difference?

- Part 6. Can I use a 24v power supply on a 12v device?

- Part 7. Practical uses

- Part 8. Common faults & deep troubleshooting

- Part 9. FAQs

Key Takeaways

- A 24V power supply converts AC (or DC) into a regulated 24V DC output that’s stable enough for industrial, lighting, and automation systems.

- You’ll usually choose between linear and switch‑mode designs — each with pros and cons depending on heat, efficiency, and noise.

- Real‑world applications range from LED lighting to CNC machines, robotics, and telecom equipment.

- Practical selection means understanding current, power (wattage), and environmental demands — not just the 24V label.

- Troubleshooting simple issues (like dropouts or overheating) often comes down to wiring, load requirements, or mismatch in ratings.

Part 1. How a 24V power supply works?

A 24V power supply is more than a box that outputs voltage. Here’s a detailed breakdown:

- Transformer (for AC input): Reduces mains voltage to a safer level. For DC input, this step is skipped.

- Rectifier: Converts AC to DC, but the DC is still “rough” with ripples.

- Filter (capacitors/inductors): Smooths the DC waveform for stable voltage.

- Voltage Regulator: Maintains output at 24V despite changes in load or input.

- Protection Circuits: Overcurrent, short-circuit, overvoltage, and thermal protection prevent damage to both supply and load.

Ripple voltage above 50mV can affect sensitive electronics like microcontrollers or communication devices. Using additional LC filters can reduce ripple without replacing the supply.

Part 2. Types of 24V power supplies?

Not all 24V power supplies are created equal. At a high level, they fall into a few categories, and your choice affects efficiency, noise, and size.

| Type | Efficiency | Noise | Heat | Best Use |

|---|---|---|---|---|

| Linear | 50–70% | Very Low | High | Audio equipment, lab setups, noise-sensitive electronics |

| Switch-Mode (SMPS) | 80–95% | Medium | Moderate | DIY projects, LED systems, robotics |

| Regulated DC Supply | 70–90% | Low | Moderate | Industrial automation, test equipment |

| Unregulated DC Supply | N/A | High | Variable | Cheap, tolerant loads, hobby electronics |

A linear supply gives you exceptionally clean output, which is ideal for audio gear or precision circuitry, but it’s bulkier and warmer.

On the other hand, a switch‑mode power supply (SMPS) is compact and efficient, and its design — switching the current rapidly — is what gives it an edge in almost every modern application.

Part 3. Key parameters of a 24V power supply

This is a typical spec range you might see on a 24V DC power supply — useful when comparing models:

| Spec | Typical Range |

|---|---|

| Output Voltage | 24V DC |

| Output Current | 1–10A (varies by model) |

| Power Rating | 24–240W |

| Efficiency | Up to ~90% |

| Ripple & Noise | < 50 mV |

- Output Voltage: This should be stable at 24V. Even minor fluctuations can impact performance in sensitive devices.

- Output Current: Measured in amps, this tells you how much current the supply can deliver. Choose a power supply that meets or exceeds your device’s current requirements.

- Wattage: A combination of voltage and current, wattage represents the power capacity. Make sure the wattage is sufficient for your devices’ needs.

- Efficiency: Higher efficiency means less wasted energy. Opt for a high-efficiency power supply if you’re running the device for long hours.

- Load Regulation: Indicates how stable the output voltage remains as the load changes. The more stable, the better.

- Ripple and Noise: Low ripple and noise are crucial for sensitive electronics. Look for specifications that promise minimal interference.

- Operating Temperature Range: If you’re using your power supply in extreme conditions, ensure it can withstand the environment.

These parameters are critical, and they directly influence how well your power supply will perform in real-world conditions.

Part 4. How to choose the right 24V power supply?

Choosing a 24V power supply isn’t just about matching the voltage. To get reliable, long-lasting performance, you need to consider load, environment, and even transient conditions. Here’s how you can approach it:

1 Step 1: Calculate Total Load Accurately

Don’t just sum up nominal currents. Include a margin for startup surges (like motor spin-up or LED inrush). A simple formula:

Itotal=(I1+I2+…+In)×1.2

This 1.2 factor gives a 20% headroom for transient peaks. For example, if your devices draw 4A combined, a supply rated at at least 4.8A is recommended.

2 Step 2: Wattage Check

Power rating must cover the total load:

W=V×Itotal

So, for 24V × 4.8A = 115.2W, pick a 120–150W supply to avoid running at maximum capacity continuously.

3 Step 3: Temperature & Environmental Derating

Power supplies produce heat, and hot environments reduce their output capacity. Manufacturers often provide derating charts: for every 10°C above 25°C, derate by 5–10%.

- Example: a 120W supply in a 45°C ambient might only safely deliver ~100W.

4 Step 4: Input Voltage Flexibility

Check if your supply handles AC 110V–240V or DC variations. Some industrial setups have unstable AC; a supply rated for a wide input range ensures stability.

5 Step 5: Ripple & Noise Requirements

Sensitive electronics (audio, sensors, PLCs) need low ripple. For <50mV ripple, linear or well-filtered SMPS is ideal. For robust loads like motors or LED strips, a slightly higher ripple is usually acceptable.

If your load varies rapidly, look at the load regulation spec — it tells you how much the voltage might dip when your device draws peak current.

Part 5. 24v Power supply vs. 12v power supply: what’s the difference?

While both 24V and 12V power supplies serve their purpose, they are best suited for different situations. Here’s how they differ:

- Power and Efficiency: A 24V power supply is generally more efficient than a 12V one for high-powered devices, as it requires less current to deliver the same power, reducing heat generation.

- Safety: Higher current at 12V can lead to overheating, so 24V is preferred for applications that demand more power.

- Device Compatibility: 12V power is more common for smaller electronics, like household items and automotive devices. 24V, on the other hand, is often found in industrial equipment and large-scale setups.

- Battery Life: Devices designed for 24V generally offer longer battery life, as the power is distributed more efficiently.

Mastering the 12V Power Supply: Your Essential Guide

Part 6. Can I use a 24v power supply on a 12v device?

This is a common question, and the answer is generally “No.” A 24V power supply delivers twice the voltage a 12V device is designed to handle, which can lead to overheating, damage, or even complete failure.

If you’re in a pinch and only have a 24V supply, consider using a DC-DC converter to safely step down the voltage to 12V.

However, it’s almost always better to use the correct power supply for the device to avoid the risk of serious damage.

Part 7. Practical uses

Now that you’ve picked a supply, here are some tricks to get the most out of it:

1. Long Wire Runs & Voltage Drop

- Voltage drop can be significant on long cables. Use this formula:

Vdrop=I×R

Where RRR is the wire resistance. For example, a 5A load over 10m of 1.5mm² copper wire drops ~0.2V — not huge, but noticeable in sensitive circuits. Increasing wire gauge reduces this drop.

2. Start-Up Current Surges

- Motors, pumps, or large LED arrays draw more current at start.

- Ensure your supply can handle peak inrush current for at least a few milliseconds. Otherwise, voltage may sag or the supply may shut down.

3. Thermal Management

- Keep supplies ventilated; don’t enclose them in tight, hot cabinets unless derated.

- Heat sinks or small fans can extend lifespan. Continuous operation at max temperature dramatically shortens life.

4. Noise Mitigation

- For sensitive electronics, add an LC filter or use shielded cables.

- Avoid routing signal wires parallel to high-current lines to reduce interference.

5. Parallel & Series Use

- Parallel: Can increase current capacity but ensure supplies are load-sharing compatible.

- Series: Rarely done; only if voltage needs to be doubled, and the supplies must be isolated.

6. Documentation & Datasheet Reference

- Always check load regulation, ripple, and startup behavior in datasheets. Real-world performance often differs from nominal ratings.

Part 8. Common faults & deep troubleshooting

Even well-chosen 24V supplies can run into issues. Here’s a practical, step-by-step approach to troubleshoot:

Issue 1: Voltage Drops or Devices Reset

- Cause: Load exceeds supply capacity or long cable drop.

- Check: Measure current draw; verify wire gauge and cable length.

- Solution: Upgrade supply, add another unit, or adjust wiring.

Issue 2: Overheating / Thermal Shutdown

- Cause: High ambient temperature, overloading, poor ventilation.

- Check: Measure surface temperature; compare to manufacturer max ambient rating.

- Solution: Increase airflow, reduce load, or derate the supply.

Issue 3: Ripple / Noise Affecting Devices

- Cause: Switching noise or insufficient filtering.

- Check: Use oscilloscope to observe ripple voltage.

- Solution: Add LC filters, use twisted pair wires, or switch to a linear supply.

Issue 4: Supply Won’t Turn On / Fuse Blown

- Cause: Short circuit or reverse polarity.

- Check: Inspect wiring and devices; measure input voltage.

- Solution: Correct wiring; replace fuses; add reverse-polarity protection diode if needed.

Issue 5: Inconsistent Startup Behavior in Motors or LEDs

- Cause: High inrush current causing temporary voltage sag.

- Solution: Choose a supply with higher peak current capacity, or add a soft-start circuit.

- Pro Tip: Keep a multimeter and a scope handy — real-time voltage/current measurements are the fastest way to pinpoint issues.

Part 9. FAQs

Can I use a 24V supply to charge a 24V battery directly?

Not all 24V supplies are suitable for battery charging. You need a regulated constant-current charger designed for the battery type to avoid overcharging.

How do I test if my 24V power supply is delivering true 24V?

Use a multimeter under load, not just no-load voltage, to check real output. Load can reveal voltage drops not visible otherwise.

What’s the difference between isolated and non-isolated 24V power supplies?

Isolated supplies separate input and output for safety; non-isolated ones connect directly, which can risk ground loops or shock in some setups.

Can I stack multiple 24V supplies for higher voltage?

Only if they are fully isolated. Connecting in series without isolation can damage supplies and equipment.

Why do some 24V SMPS units hum or buzz?

Humming usually comes from magnetostriction in transformers or inductors. It’s normal at light loads but excessive buzzing may indicate component stress.

Can 24V power supplies be used for Raspberry Pi or Arduino projects?

Only if paired with a DC-DC step-down converter. Supplying 24V directly can fry low-voltage microcontrollers.

Related Tags:

More Articles

A Simple Guide to 3.7V 2000mAh Li Ion Batteries

Is a 3.7V 2000mAh battery enough for your device? Learn runtime, replacement rules, connector types, and how to avoid common battery mistakes.

How Much Does a Golf Cart Battery Weigh?

Learn how golf cart batteries affect total golf cart weight and size, with average weight ranges and standard dimensions for electric golf carts.

Top 20 Lithium Ion Battery Manufacturers

2026 guide to top 10 lithium-ion battery manufacturers, covering small & large companies, applications, technology strengths, and selection tips.

How to Charge a LiPo Battery Safely and Correctly

Learn how to safely charge your LiPo batteries, avoid overcharging, and choose the best chargers for longer battery life and safety.

Essential LFP Battery Raw Material: LFP Cathode Material

Discover the benefits of lithium iron phosphate (LFP) battery cathodes. Learn why they’re a smart choice for energy storage today.