- Part 1. What is battery balancing?

- Part 2. How does battery balancing work?

- Part 3. Types of battery balancing

- Part 4. Passive balancing

- Part 5. Active balancing

- Part 6. Why is battery balancing necessary?

- Part 7. How does a battery balancer work?

- Part 8. Advantages of using a battery balancer

- Part 9. Applications of battery balancers

- Part 10. How to choose the right battery balancer?

- Part 11. Battery balancer FAQs

Battery balancers ensure stable voltage across all cells in a lithium battery pack, improving performance, lifespan, and safety. In applications from EVs and solar storage to industrial ESS and robotics, even small voltage differences can reduce capacity, accelerate aging, and create safety risks. This guide covers how battery balancers work, key balancing methods, benefits, and tips for selecting the right balancer for your lithium battery system.

Part 1. What is battery balancing?

Battery balancing is the process of equalizing the voltage or state of charge (SOC) of all cells in a battery pack to prevent overcharge, over-discharge, and capacity loss. It keeps every cell operating within a safe range, improves cycle life, and ensures the pack delivers its full rated capacity.

- Problem: Cells drift apart due to aging, temperature differences, and inconsistent manufacturing.

- Scenario: EV battery packs, LiFePO4 solar banks, or lithium batteries in parallel show early cutoff or reduced runtime.

- Solution: A battery balancer or balancing circuit redistributes charge—passively or actively—to keep cells matched.

Battery balancing equalizes the state of charge (SOC) across all cells in a multi-cell battery pack. This technique maximizes the battery pack’s overall capacity and lifespan while ensuring safe operation.

Due to manufacturing variations, temperature differences, and usage patterns, individual cells can develop differences in capacity and charge levels in a multi-cell battery pack. Over time, these discrepancies lead to reduced overall pack capacity, decreased performance, and potential safety hazards.

Battery balancing aims to address these issues by:

- Equalizing the charge levels across all cells

- Preventing overcharging or over-discharging of individual cells

- Maximizing the usable capacity of the battery pack

- Extending the overall lifespan of the battery

Designing a battery balancing system

Designing an effective battery balancing system requires careful consideration of several factors:

- Battery chemistry: Different chemistries (lithium-ion, lead-acid, LiFePO4) require different balancing control.

- Number of cells: More cells increase circuit complexity.

- Balancing method: Choose passive or active based on speed and efficiency requirements.

- Balancing current: Determines how quickly voltage differences can be corrected.

- Monitoring and control: Requires precise cell voltage and temperature monitoring.

- Safety features: Protection against overcharge, over-discharge, and thermal runaway.

Part 2. How does battery balancing work?

Battery balancing works by redistributing charge among cells in a battery pack to achieve a uniform state of charge. The process typically involves the following steps:

- Cell monitoring: The BMS continuously monitors the voltage and temperature of each cell.

- Imbalance detection: The system identifies cells with higher or lower charge than average.

- Balancing activation: Balancing circuits activate when imbalance exceeds a threshold.

- Charge redistribution: Charge is removed (passive) or transferred (active) between cells.

- Equalization: The process continues until all cells reach similar SOC levels.

- Continuous monitoring: The BMS balances during charge, and advanced systems balance during discharge or idle.

Quick Answer: How a Battery Balancer Works

A battery balancer works by detecting voltage differences between cells and either removing excess charge (passive) or transferring it to weaker cells (active). The goal is to keep all cells at similar SOC levels so the pack charges evenly and delivers maximum usable energy.

- When to use it: Lithium batteries in parallel, RV/solar systems, EV packs, LiFePO4 storage banks.

- Common symptoms: Early high-voltage cutoff, reduced capacity, imbalance >15mV.

- What helps: Installing a lithium battery balancer or integrating a cell-balancing circuit inside a BMS.

Part 3. Types of battery balancing

There are two main battery balancing techniques: passive and active. Each method has advantages and limitations, making it suitable for different applications.

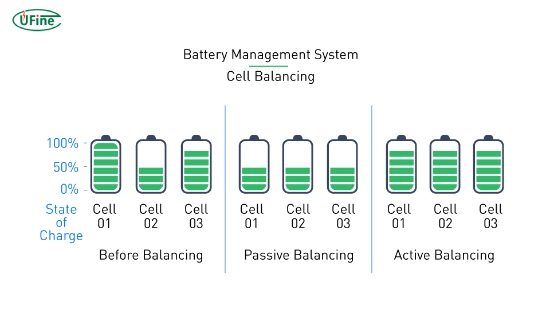

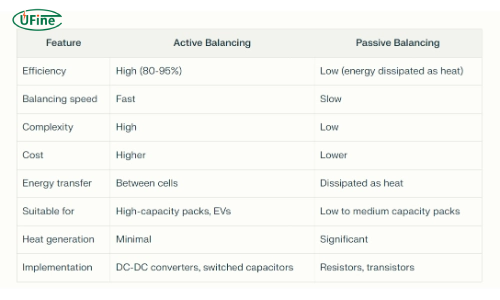

Active vs. passive balancing

Passive balancing removes excess energy from higher-charged cells through resistors until all cells reach the same voltage. It is cost-effective and simple but less efficient and generates heat.

Active balancing transfers energy between cells using DC-DC converters or switched capacitors. This method is more efficient and provides faster equalization but at higher cost and circuit complexity.

Part 4. Passive balancing

Passive balancing is the most commonly used method in consumer BMS designs due to its simplicity and low cost. The process removes excess energy from higher-voltage cells by dissipating it as heat using resistors.

How passive balancing works

The BMS identifies cells with higher voltage and activates a resistor bypass circuit to discharge them slightly. This continues until all cells reach similar SOC levels.

- Balancing trigger: Usually starts above 3.45–3.50V for LiFePO4 or during constant-voltage charging.

- Heat generation: Excess energy is burned as heat, requiring thermal management.

- Low balancing current: Typically 30–150 mA depending on BMS design.

Advantages of passive balancing

- Low complexity

- Lower cost of components

- Simple, reliable circuit topology

- Effective for light to moderate imbalance

Limitations of passive balancing

- Energy is wasted as heat

- Slow balancing speed when cells are deeply imbalanced

- Not suitable for large EV packs requiring fast equalization

- Often balances only during charging

Part 5. Active balancing

Active balancing redistributes charge between cells instead of dissipating it as heat. This results in more efficient energy usage and significantly faster balancing speed, making it ideal for EVs, energy-storage systems, and large-capacity lithium battery banks.

How active balancing works

Active balancers use inductors, transformers, or capacitors to move energy from higher-voltage cells to lower-voltage cells.

- Energy transfer: From strong cells to weak cells.

- Continuous balancing: Works during charge, discharge, and idle states.

- High balancing current: Ranges from 0.5A to >5A depending on model.

Advantages of active balancing

- Much faster balancing, especially for large packs

- Energy is conserved instead of wasted

- Better for high-capacity cells and deep imbalance

- Improved cycle life due to gentler cell management

Limitations of active balancing

- Higher cost compared to passive systems

- More complex architecture (inductors, MOSFET arrays, DC-DC structures)

- Requires stricter thermal and electromagnetic design

Part 6. Why is battery balancing necessary?

Battery balancing is essential because even small differences in cell characteristics can lead to significant imbalance over time. Without balancing, the weakest cell limits the entire pack.

Imbalance problems include:

- Reduced capacity and shorter runtime

- Premature high-voltage or low-voltage cutoff

- Increased heat generation during charge/discharge

- Accelerated cell degradation

- Safety risks such as swelling, overcharge, and thermal runaway

What causes cells to become imbalanced?

- Manufacturing variations: No two cells are perfectly identical.

- Temperature differences: Cells age differently depending on thermal exposure.

- Internal resistance drift: Occurs naturally with charge cycles.

- Capacity mismatch: Some cells hold more energy than others.

- Aging and cycle count differences

What happens without balancing?

Over time, the pack becomes limited by the weakest cell. Even if other cells are healthy, the BMS must protect the lowest cell from over-discharge or over-charge, reducing usable capacity by 10–30% or more.

Balancing ensures:

- Uniform SOC among cells

- Longer cycle life

- Safer operation

- Maximum usable capacity

- Optimal charging efficiency

Part 7. How does a battery balancer work?

A battery balancer equalizes voltage among individual cells by transferring charge from higher-voltage cells to lower-voltage ones. This keeps all cells within a narrow voltage range, protects against overcharging, and improves cycle consistency. A high-performance lithium battery balancer typically uses passive bleeding, active energy transfer circuits, or hybrid balancing algorithms.

Working Principles

Step 1 – Voltage Monitoring

Each cell’s real-time voltage is measured through a sensing module.

Step 2 – Imbalance Detection

When cell deviation exceeds the preset threshold (e.g., 10–30 mV), balancing starts.

Step 3 – Charge Transfer or Bleeding

Energy is moved from high-voltage cells to lower ones (active balancing) or released as heat (passive balancing).

Step 4 – Equalization Completion

Balancing stops when voltage difference falls below the target range.

Internal Components

- Voltage and temperature sensors

- Balancing resistors or inductors

- MOSFET switching devices

- Microcontroller for algorithm control

- Heat dissipation and protection circuits

Balancing Algorithms

Modern balancers use multiple algorithms for improving balancing speed and reducing energy loss. Common approaches include:

- Voltage-based threshold control

- ΔV deviation detection

- State-of-charge (SOC) prediction

- Temperature-adaptive balancing

- Active energy-shuttle switching

Part 8. Advantages of using a battery balancer

Integrating a battery balancer significantly enhances reliability, cycle consistency, and safety. Below are the key benefits aligned with lithium battery pack design and long-term performance.

- Longer Battery Lifespan: Balanced cells degrade more uniformly, improving usable cycles by 20–40%.

- Increased Usable Capacity: Overall pack capacity increases when all cells reach the same SOC window.

- Improved Safety: Balancing reduces overcharge/over-discharge risks that can trigger thermal runaway.

- Enhanced Fast-Charging Performance: Balanced cells allow higher charging current without triggering safety cutoffs.

- Optimized Energy Efficiency: Active balancers reduce energy waste and maintain stability during heavy loads.

- Better Pack Reliability: Particularly crucial for EVs, solar storage, robotics, UPS, and off-grid systems.

Part 9. Applications of battery balancers

Battery balancers are essential in systems that require consistent voltage, high cycle stability, and long-term operational safety. Below are major fields where balancing is mandatory or highly recommended.

Electric Vehicles (EVs) & Hybrid Vehicles

EV battery packs contain hundreds of cells connected in series. A lithium battery balancer ensures uniform charge distribution and prevents early cell failure, which improves driving range and safety.

Solar Energy Storage Systems

Off-grid and hybrid solar installations rely on LiFePO4 and NMC battery banks. A balancer avoids capacity loss caused by daily cycling and temperature fluctuations.

Energy Storage Systems (ESS)

For home ESS, containerized BESS, telecom towers, and commercial microgrids, balancing is critical for maintaining consistent voltage and preventing pack drift over long operational periods.

Marine & RV Battery Banks

Multi-battery configurations in parallel/series setups benefit from balancers to prevent uneven wear and unexpected shutdowns.

Robotics, Drones, UPS, and Industrial Equipment

High-performance lithium packs with repeated high load cycles experience significant imbalance over time; balancing stabilizes power delivery.

Part 10. How to choose the right battery balancer?

Choosing the appropriate balancer requires evaluating pack architecture, voltage, chemistry, and balancing speed. Below are essential selection guidelines.

Key Selection Criteria

- Battery Chemistry: LiFePO4, NMC, NCA, LTO, lithium-ion pouch cells, etc.

- Total Voltage / Series Count: e.g., 4S, 8S, 12S, 16S, 48V packs.

- Balancing Type: Passive vs. Active Energy Transfer.

- Balancing Current: 30 mA – 2 A depending on size and application.

- Continuous vs. On-Demand Balancing: Real-time balancing preferred for EV/ESS.

- Temperature & Protection Features: Over-voltage, over-current, thermal protection.

- Communication Support: CAN, UART, RS485 for advanced BMS integration.

When You Need a High-Current Active Balancer

- Large battery banks (48V/51.2V ESS)

- Electric vehicles or high-drain applications

- Systems suffering from fast voltage drift

- Packs with mixed-age or unmatched cells

Part 11. Battery balancer FAQs

What is a battery balancer?

A battery balancer is a device that equalizes individual cell voltages in a series-connected battery pack to prevent overcharge, over-discharge, and capacity loss.

Do I need a battery balancer for my lithium battery pack?

Yes. Any pack with cells in series requires balancing to maintain performance, ensure consistent state-of-charge, and avoid early cell degradation or safety issues.

How does a battery balancer extend battery life?

It keeps all cells operating within the same voltage window, reducing stress on weaker cells and enabling more usable capacity across every charge cycle.

What is the difference between a BMS and a battery balancer?

A BMS protects the battery by monitoring voltage, current, and temperature, while a balancer actively corrects cell imbalance through passive discharge or active energy transfer.

Is active balancing better than passive balancing?

Active balancing is preferred for EV, ESS, and high-capacity lithium packs because it transfers energy efficiently and equalizes faster, while passive balancing is slower and wastes heat.

Can I add a balancer to an existing lithium battery pack?

Yes. Most LiFePO4, NMC, and LTO battery packs with accessible series terminals can accept an external balancer for improved performance and safety.

What balancing current do I need?

Small packs: 30–100 mA. Medium solar/off-grid packs: 200–600 mA. Large ESS and EV systems: 1–2 A active balancing current.

Can a battery balancer fix weak or damaged cells?

No. A balancer cannot repair degraded cells; it only keeps healthy cells synchronized to prevent imbalance from worsening.

Related Tags:

More Articles

A Complete Guide to the Best Batteries for Flashlights

Compare the best batteries for flashlights, including AA, AAA, 18650, 21700, CR123A. See which battery offers the best brightness, runtime, and reliability.

How Long Do Rechargeable AA Batteries Last?

How long do rechargeable AA batteries last? Compare NiMH and lithium AA lifespan, recharge cycles, key factors, and performance vs alkaline batteries.

How Much Current Can a 9V Battery Really Supply?

Discover how many amps a 9V battery can supply, its actual current output, discharge rate, and capacity for alkaline, lithium, and rechargeable 9V batteries.

12V STD vs 12V AGM: Meaning, Differences, and Which Is Better

Understand what STD and AGM batteries mean, their key differences, and which 12V battery fits your needs best in 2026.

Battery Reconditioning Explained: A Comprehensive Guide

Learn what battery reconditioning is, how it works, how long it takes, and when reconditioning chargers are used for lead-acid and lithium-ion batteries.