- Part 1. What are M6/M8 lithium battery terminals?

- Part 2. Why convert M6/M8 terminals to SAE posts?

- Part 3. What hardware is needed to convert M6/M8 terminals to SAE posts?

- Part 4. Step-by-step: How to convert M6/M8 terminals to SAE posts

- Part 5. Common mistakes when converting M6/M8 terminals to SAE posts

- Part 6. Performance considerations: Will the adapter affect efficiency?

- Part 7. Best adapter materials for stable lithium performance

- Part 8. When NOT to use an SAE adapter (best with ring terminals)

- Part 9. Safety considerations for lithium terminals

- Part 10. FAQ: Converting M6/M8 lithium battery terminals to SAE posts

Many lithium and LiFePO₄ battery packs — especially those designed for energy storage, solar systems, mobility devices, UPS units, and small power systems — use M6 or M8 threaded terminals rather than traditional SAE automotive posts. These threaded terminals allow secure installation, higher torque precision, and better vibration resistance.

However, many real-world applications still rely on SAE-style clamps or post-type connectors. When installing lithium batteries in older RVs, boats, vehicles, golf carts, or equipment designed for lead-acid batteries, users often need to convert M6/M8 terminals to standard post terminals.

This guide explains exactly how to perform the conversion safely, what adapters you need, how to avoid damaging lithium terminals, and how to ensure stable conductivity and long-term reliability.

Part 1. What are M6/M8 lithium battery terminals?

M6 and M8 terminals are metric threaded inserts commonly used in lithium and LiFePO₄ batteries. Their names derive from the bolt diameter:

- M6 terminal: 6 mm thread

- M8 terminal: 8 mm thread

These terminals provide:

- High clamping force

- Precise torque control

- Lower internal resistance

- Excellent vibration performance

- Compatibility with ring lugs

Lithium batteries prefer threaded terminals because they can support:

- High discharge currents

- Frequent cycling

- Stable electrical contact

However, automotive and RV systems often use SAE posts, which require a different connection style — hence the need for a conversion adapter.

Part 2. Why convert M6/M8 terminals to SAE posts?

Users convert lithium terminals to SAE posts for several common reasons:

- Compatibility with existing battery cables

Older vehicles and boats use clamp-style connectors that require round posts.

- Quick installation and removal

SAE clamps are quicker to release in service situations.

- Connecting multiple accessories

Some systems rely on posts for:

- Fuse blocks

- Inline monitors

- Auxiliary accessory rings

- Parallel or series wiring using automotive hardware

Many installers reuse existing wiring to save cost and time.

- OEM equipment design

Some devices are simply built for post terminals and cannot accept ring terminals without modification.

Part 3. What hardware is needed to convert M6/M8 terminals to SAE posts?

To perform the conversion safely, you need the correct adapters and installation hardware.

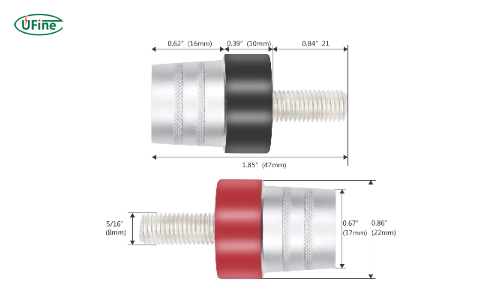

M6-to-SAE or M8-to-SAE post adapters

These adapters screw directly onto the M6/M8 terminals and convert the flat threaded interface into a round SAE automotive post.

Look for:

- Solid copper or brass

- Precision machining

- Wide contact base

- Nickel or tin plating

- Correct thread depth

Avoid adapters made from cheap steel alloys — they increase resistance and heat.

Correct mounting bolts

A suitable stainless-steel or treated steel bolt (NOT soft zinc) is required:

- M6 terminal → M6 bolt

- M8 terminal → M8 bolt

Length should match the terminal depth to avoid bottoming out.

Torque wrench

Threaded lithium terminals are sensitive to over-torque.

Typical torque values:

- M6: 4–6 N·m

- M8: 6–8 N·m

Dielectric grease

Prevents oxidation and improves long-term stability.

Cleaning tools

A brush or cloth to remove dust/oil before installation.

Part 4. Step-by-step: How to convert M6/M8 terminals to SAE posts

Below is the recommended conversion procedure used by professional installers and lithium battery technicians.

Step 1. Inspect the battery terminal surfaces

Check for:

- Dust

- Shipping oil

- Oxidation

- Thread damage

If surfaces are contaminated, clean them with a dry cloth. Do not use conductive grease directly on threads.

Step 2. Verify the adapter size

Match your terminal:

- M6 lithium terminal → M6-to-SAE adapter

- M8 lithium terminal → M8-to-SAE adapter

Warning: Never force-fit an adapter with different threading. It will damage the terminal and void most warranties.

Step 3. Prepare the adapter

Apply a thin layer of dielectric grease on the outside surface of the adapter base, not on the threads.

This improves corrosion resistance without interfering with thread torque.

Step 4. Hand-tighten the adapter onto the terminal

Turn the adapter clockwise with your fingers first.

This ensures you do not cross-thread the bolt. If resistance occurs immediately, stop and re-align.

Step 5. Tighten with a torque wrench

Set torque according to the terminal size:

- M6 → 4–6 N·m

- M8 → 6–8 N·m

Over-tightening can:

- Strip the insert

- Crack the terminal housing

- Damage internal busbars

Under-tightening can:

- Cause micro-arcing

- Increase resistance

- Generate heat

Precision is essential. Lithium terminals require correct torque more than lead-acid posts.

Step 6. Install the vehicle/RV/boat battery cable clamp

Place the clamp over the SAE post adapter.

Ensure full contact around the post:

- No gaps

- No tilting

- Clamp fully seated

Tighten clamp to manufacturer specifications (typically 8–12 N·m).

Step 7. Check for proper movement and stability

Try moving the clamp side-to-side with moderate force.

A proper installation will feel:

- Solid

- Stable

- Without rotational play

If movement is detected, remove, clean, and reinstall.

Step 8. Perform electrical testing (optional but recommended)

Measure voltage at the adapter using a multimeter.

Then activate a high-current load (e.g., inverter startup) and confirm:

- Minimal voltage drop

- No heating

- Stable contact

A copper adapter should show almost no additional drop compared to a direct ring-lug connection.

Part 5. Common mistakes when converting M6/M8 terminals to SAE posts

Avoid the following installation errors that frequently cause customer issues:

- ❌ Over-tightening the threaded bolt — This is the #1 cause of terminal damage in lithium batteries.

- ❌ Using cheap stainless-steel adapters — High resistance leads to heat and voltage sag.

- ❌ Stacking two adapters — “Adapter-on-adapter” increases failure risk.

- ❌ Using the wrong bolt length — Bolts that bottom out damage terminal inserts.

- ❌ Installing clamps on dirty or oily posts — Reduces electrical contact.

- ❌ Applying grease directly to threads — Prevents correct torque from being applied.

- ❌ Using JIS-to-SAE adapters on M6/M8 terminals — Thread mismatch causes stripped terminals.

Part 6. Performance considerations: Will the adapter affect efficiency?

Adding an adapter introduces one additional interface:

Terminal → Adapter → Clamp

Each interface has:

- Resistance

- Pressure surface

- Thermal behavior

However, with high-quality copper adapters, performance loss is extremely small.

Typical resistance added:

- High-grade copper: 0.01–0.05 mΩ

- Brass: 0.10–0.20 mΩ

- Low-grade alloys: 0.30–0.80 mΩ (avoid)

At 150A discharge, a copper adapter may add only 0.002–0.006V drop — negligible for most systems.

Voltage drop becomes problematic only with:

- Poor materials

- Loose torque

- Corrosion

- Undersized contact surfaces

In a solar, RV, UPS, or mobility system, a properly installed adapter performs almost identically to a direct ring-lug connection.

Artikel Terkait: Battery Post Adapter Guide: Types, Compatibility, and When You Actually Need One

Part 7. Best adapter materials for stable lithium performance

Material selection directly affects stability.

Best: Pure copper (highest conductivity)

- Ideal for high-current applications

- Lowest resistance

- Excellent thermal performance

Good: Brass (acceptable for most users)

- Moderate resistance

- Widely used in automotive adapters

Avoid: Stainless steel or alloy blends

- Extremely high resistance

- Noticeable heat under load

- Common in cheap online listings

For lithium battery systems, copper is strongly recommended.

Part 8. When NOT to use an SAE adapter (best with ring terminals)

SAE adapters provide compatibility, but they are not ideal in every scenario.

Avoid adapters when:

- You have direct access to ring terminals

- The system draws extremely high current (300A+)

- The battery is used in heavy vibration environments (ATVs, off-road vehicles)

- You need the lowest possible resistance

For these cases, using direct ring lugs on the M6/M8 terminals is the best performance choice.

Part 9. Safety considerations for lithium terminals

Because lithium batteries rely on:

- Aluminum busbars

- Copper inserts

- Precise compression force

Any improper installation can cause long-term damage.

Safe installation rules:

- Always use a torque wrench

- Avoid stacking washers or adapters

- Keep surfaces clean and dry

- Re-check torque every 6–12 months in mobile applications

- Use only high-quality adapters

Following these practices ensures long service life and stable performance.

Part 10. FAQ: Converting M6/M8 lithium battery terminals to SAE posts

Can I use any type of adapter to convert M6/M8 terminals to SAE posts?

Answer: No, use copper or brass adapters for the best conductivity. Avoid low-quality materials like stainless steel.

What are the risks of using a low-quality adapter?

Answer: Low-quality adapters can cause voltage drop, heat buildup, and corrosion, reducing performance and stability.

How do I prevent damaging the lithium battery terminals?

Answer: Use a torque wrench to tighten to the correct values (4–6 N·m for M6, 6–8 N·m for M8) and apply dielectric grease on the adapter’s base.

Can converting M6/M8 terminals to SAE posts affect performance?

Answer: Yes, but copper adapters cause minimal impact. Poor materials and improper installation may lead to voltage loss and heat buildup.

When should I avoid using an adapter for conversion?

Answer: Avoid adapters in systems with high current (>300A) or high vibration, where they might fail or cause performance issues.

Related Tags:

More Articles

Capacitor vs Battery: What is the Difference?

Capacitor vs battery explained in detail. Learn the difference between capacitor and battery in energy storage, charging speed, lifespan, and real applications.

18650 Battery vs AA: Which Is Better for Your Device?

Compare 18650 vs AA batteries in capacity, voltage, rechargeability, and applications. Learn which battery type fits high-drain or everyday devices.

What is the Difference Between Battery Cell, Battery Control Module, and Battery Pack?

Compare battery cells, modules, and packs. Learn functions, design differences, control modules, and selection tips for EV, ESS, and industrial use.

How to Prevent LiPo Battery Explosion?

Can LiPo batteries explode or catch fire? Learn key causes of LiPo battery fires and proven charging, storage, and handling tips to reduce explosion risk.

Aluminium Ion Battery vs Lithium-Ion: A Detailed Comparison

Compare aluminium ion battery vs lithium-ion battery in energy density, charging speed, safety, cost, and uses. A practical guide for engineers and buyers.