- Part 1. What is the real price range of 7.2V battery and charger in 2026?

- Part 2. How battery chemistry changes 7.2V battery and charger pricing?

- Part 3. How capacity (mAh) affects 7.2V battery and charger cost?

- Part 4. How discharge current design changes 7.2V battery and charger pricing?

- Part 5. How chargers affect total 7.2V battery and charger system cost?

- Part 6. How certifications affect 7.2V battery and charger pricing?

- Part 7. How connector, cable, and structure affect 7.2V battery and charger cost?

- Part 8. Standard vs custom 7.2V battery and charger pricing logic

- Part 9. How upgrading to lithium changes 7.2V battery and charger cost structure?

- Part 10. What is the total cost of ownership of a 7.2V battery and charger?

- Part 11. What hidden cost traps should buyers avoid when buying 7.2V battery and charger?

- Part 12. When does custom 7.2V battery and charger become the cheaper option?

- Part 13. FAQ-7.2V battery and charger pricing

Why 7.2V battery and charger prices vary so much?

If you search for a 7.2V battery and charger, you will quickly find:

- Some packs are priced at only a few dollars

- Others cost several times more for the “same” 7.2V rating

This confuses most buyers and often leads to wrong purchasing decisions based on unit price only. In reality, 7.2V battery and charger pricing is driven by much more than just voltage and mAh.

This guide breaks down exactly what affects the real cost in 2026, so you can judge whether a quote is cheap, overpriced, or truly cost-effective.

Part 1. What is the real price range of 7.2V battery and charger in 2026?

Instead of giving one misleading number, the market price can be divided into three clear tiers:

| Product type | Typical price range | Best for |

|---|---|---|

| Entry-level standard pack | Low | Hobby, toys, basic backups |

| Mid-range industrial pack | Medium | Tools, instruments, light industry |

| High-end custom pack | High | Medical, OEM, robotics, exports |

The same 7.2V battery and charger can differ in price by 3–6× depending on internal design and certification level.

Part 2. How battery chemistry changes 7.2V battery and charger pricing?

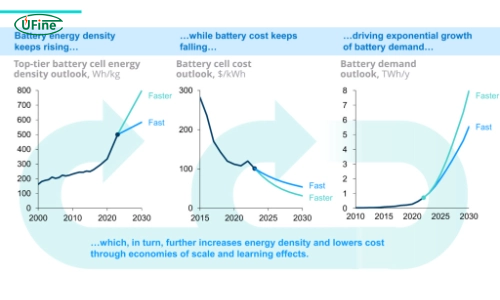

Battery chemistry is one of the largest cost drivers.

NiMH 7.2V battery and charger

- Lower cell cost

- Simpler protection design

- Lower performance per gram

Lithium 7.2V battery and charger

- Higher cell cost

- Requires BMS protection

- Higher energy density and longer lifespan

If you want to understand whether lithium’s higher price is justified for your use case, this comparison explains it clearly:

NiMH vs lithium 7.2V battery and charger

Part 3. How capacity (mAh) affects 7.2V battery and charger cost?

Capacity is the most visible price driver, but also the most misunderstood.

- Every increase in mAh increases:

- Cell material cost

- Physical size

- Charging time

- Shipping weight

But higher mAh does not equal higher power, it only increases runtime.

If you oversize capacity, you:

- Pay more than necessary

- Add weight to your device

- Extend charging time without benefit

For correct mAh selection logic, see:

7.2V battery and charger capacity guide

Part 4. How discharge current design changes 7.2V battery and charger pricing?

Two packs with the same 7.2V and 4000mAh can have very different prices because of:

- Continuous discharge current rating

- Peak current handling

- Internal resistance control

High-discharge designs require:

- High-rate cells

- Thicker nickel tabs

- Stronger BMS

- Better thermal management

These features directly raise manufacturing cost but are mandatory for tools, motors, and robotics.

Part 5. How chargers affect total 7.2V battery and charger system cost?

The charger is often ignored in pricing comparison, but it matters.

A basic charger includes:

- Fixed current

- No temperature detection

- Minimal protection

An industrial or medical charger includes:

- Smart CC/CV control

- Temperature feedback

- Multiple safety cutoffs

- Certification for global markets

A “cheap battery” paired with a poor charger often leads to:

- Overheating

- Shortened lifespan

- Safety risks

- Hidden replacement cost

Part 6. How certifications affect 7.2V battery and charger pricing?

For non-export products, certification cost is low.

For global markets, certification becomes a major cost factor.

Common certifications that raise cost:

- UN38.3 (air shipping)

- MSDS

- CE

- UL / IEC

Certification affects pricing by:

- Laboratory testing cost

- Engineering documentation

- Production audit requirements

But without them, many products cannot be shipped or insured legally.

Part 7. How connector, cable, and structure affect 7.2V battery and charger cost?

Custom mechanical design adds cost in the following ways:

- Special connectors instead of standard plugs

- Waterproof cable outlets

- Shock-resistant enclosures

- Non-standard dimensions

Each customization step adds:

- Tooling cost

- Assembly labor

- Failure-risk control cost

This is why OEM packs always cost more than off-the-shelf packs.

Part 8. Standard vs custom 7.2V battery and charger pricing logic

| Type | Unit price | Engineering cost | Best scenario |

|---|---|---|---|

| Standard pack | Lowest | None | Generic devices |

| Semi-custom pack | Medium | Low | Small OEM batches |

| Full custom pack | Highest | High | Certified, mass OEM |

However, custom packs often reduce total system cost by:

- Extending lifespan

- Reducing failure rate

- Avoiding redesign cost later

Part 9. How upgrading to lithium changes 7.2V battery and charger cost structure?

Upgrading from NiMH to lithium always increases:

- Initial purchase cost

- Charger cost

But it reduces:

- Replacement frequency

- Maintenance cost

- Downtime

- Shipping weight

If you are planning to upgrade, this guide explains the full technical process:

Part 10. What is the total cost of ownership of a 7.2V battery and charger?

True cost is not unit price, but:

- Purchase cost

- Cycle life

- Charging efficiency

- Failure rate

- Replacement frequency

In many industrial applications:

A lithium 7.2V battery and charger with higher upfront cost becomes 30–50% cheaper over 2–3 years than NiMH.

Part 11. What hidden cost traps should buyers avoid when buying 7.2V battery and charger?

- Fake high-mAh labeling

- Undersized BMS

- No real certification

- Weak nickel connections

- Charger without temperature control

These lead to:

- Warranty disputes

- Device failures

- Long-term after-sales cost

Part 12. When does custom 7.2V battery and charger become the cheaper option?

Custom becomes cheaper when you need:

- High discharge current

- Tight installation space

- Medical or industrial certification

- Long service life

- Zero-failure requirement

In these scenarios, cheap standard packs become the most expensive option over time.

Part 13. FAQ-7.2V battery and charger pricing

Why are some 7.2V battery and charger sets so cheap online?

Most ultra-cheap packs use low-grade cells, weak BMS, and have no real certification. They are suitable only for light hobby use.

Is lithium always more expensive than NiMH for 7.2V battery and charger?

At purchase, yes. Over the full lifespan, lithium is often cheaper due to longer cycle life.

Does higher mAh always mean higher price?

Usually yes, but discharge current design and certification can increase price even more than capacity.

Why do OEM quotes vary so much for the same 7.2V rating?

Because internal design, certification level, connector type, BMS grade, and quality control standards are completely different.

Related Tags:

More Articles

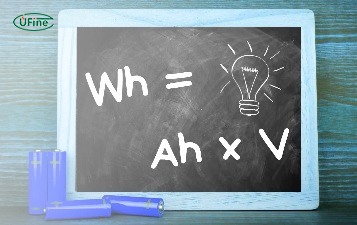

What are Watts and Watt Hours in Battery?

Understand watt vs watt-hour in batteries, how to calculate battery watt hours, and what Wh means for car batteries, devices, and energy storage.

A Complete Guide to the Best Batteries for Flashlights

Compare the best batteries for flashlights, including AA, AAA, 18650, 21700, CR123A. See which battery offers the best brightness, runtime, and reliability.

How Long Do Rechargeable AA Batteries Last?

How long do rechargeable AA batteries last? Compare NiMH and lithium AA lifespan, recharge cycles, key factors, and performance vs alkaline batteries.

How Much Current Can a 9V Battery Really Supply?

Discover how many amps a 9V battery can supply, its actual current output, discharge rate, and capacity for alkaline, lithium, and rechargeable 9V batteries.

12V STD vs 12V AGM: Meaning, Differences, and Which Is Better

Understand what STD and AGM batteries mean, their key differences, and which 12V battery fits your needs best in 2026.