- Part 1. Power challenges in smart ring devices

- Part 2. Typical battery life of smart rings on the market

- Part 3. Our smart ring battery solution overview

- Part 4. Key technologies for smart ring batteries

- Part 5. R&D support for smart ring battery development

- Part 6. Typical smart ring battery use cases

- Part 7. Charging & power system compatibility

- Part 8. Safety & reliability considerations

- Part 9. Certification & compliance support

- Part 10. From prototype to mass production

- Part 11. Looking for a custom smart ring battery solution?

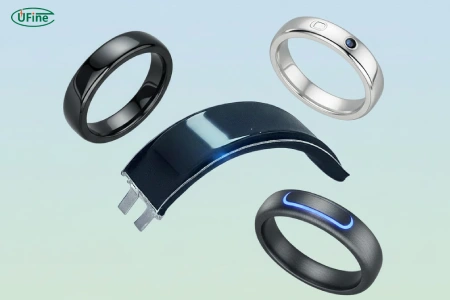

Smart Ring Battery Solutions: Smart rings represent one of the most compact and technically demanding wearable devices in the market. Due to extremely limited internal space and continuous sensing requirements, battery design becomes a critical factor affecting performance, reliability, and user experience. Ufine Battery specializes in custom curved polymer battery solutions for smart rings, providing ultra-compact, flexible, and safe power sources optimized for wearable applications. Our solutions ensure seamless integration with your industrial design while supporting long-term use and reliable performance.

Part 1. Power challenges in smart ring devices

Smart rings face unique and significant battery design challenges:

- Extremely limited internal space, requiring ultra-thin and curved battery form factors that maximize energy density.

- Battery performance expectations versus size trade-offs: unlike smartwatches, smart rings seldom exceed a few days of operation due to physical constraints.

- Continuous low-power operation requirements (health monitoring, Bluetooth communication).

- Miniaturization complexity both increases production costs and limits battery capacity scaling.

- User expectations for life, safety, and reliability, despite significant constraints on size and thickness.

These constraints make curved, flexible polymer batteries a strategic choice for smart ring applications.

Part 2. Typical battery life of smart rings on the market

Most smart rings on the market use ultra-small lithium polymer batteries with capacities typically ranging from 15 mAh to 25 mAh, due to strict size and thickness limitations.

Based on publicly available product specifications and industry reports:

- Entry-level smart rings usually offer 1–2 days of battery life

- Health-tracking smart rings typically last 2–4 days, depending on sensor usage

- Optimized premium smart rings can reach 5–7 days, achieved through low-power chipsets and highly efficient battery management

In real-world usage, battery life is heavily affected by:

- Continuous heart-rate and SpO₂ monitoring

- Bluetooth transmission frequency

- Sleep tracking duration

- Charging strategy and depth of discharge

Because of these factors, battery capacity alone does not determine smart ring battery life. Instead, optimized battery chemistry, discharge stability, and system-level power management play a critical role.

Part 3. Our smart ring battery solution overview

We provide tailored curved polymer battery solutions purpose-built for smart ring designs — combining form-factor flexibility with industry-grade performance.

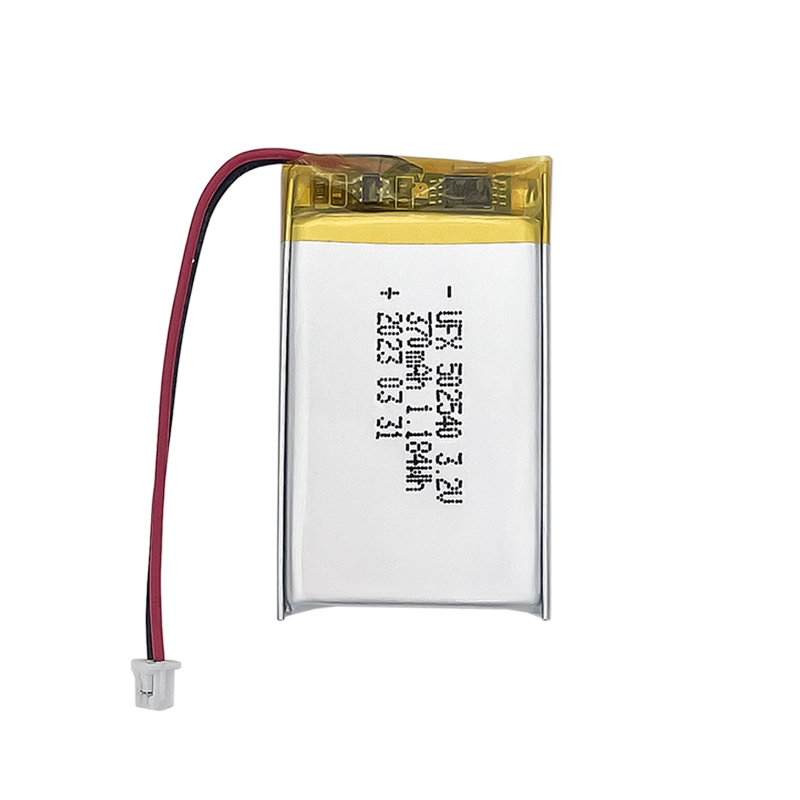

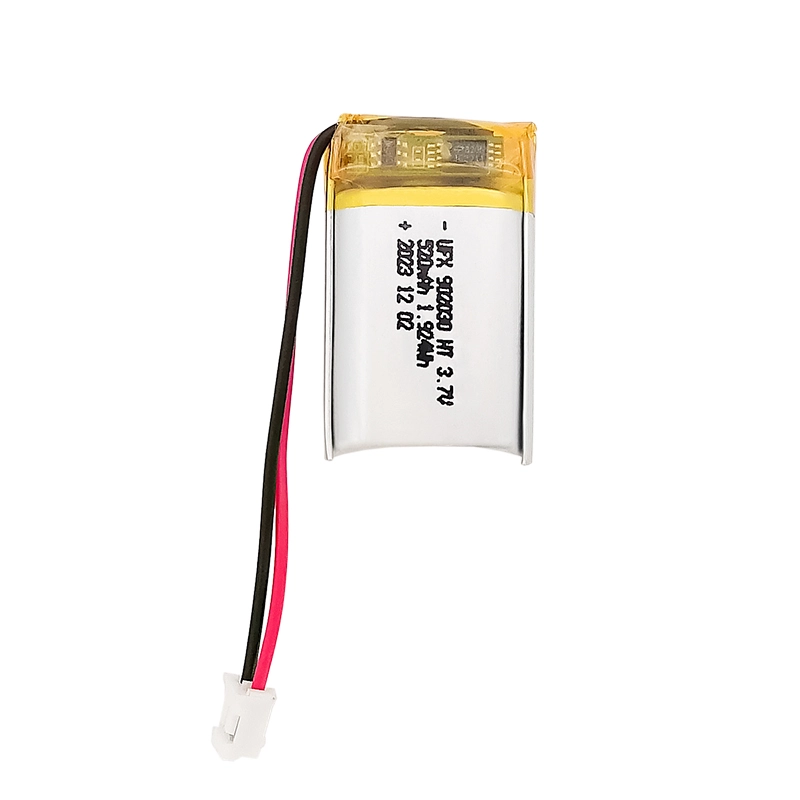

Standard Curved Polymer Battery Solution Specifications

| Feature | Specification |

|---|---|

| Battery Type | Curved Lithium Polymer (Li-Po) |

| Nominal Voltage | 3.7 V |

| Capacity Range | 16–20 mAh (expandable on request) |

| Thickness & Curvature | Designed to match smart ring form factors |

| Cycle Life | 300+ cycles (usage-optimized) |

| Operating Temp. | Wearable device optimized |

Part 4. Key technologies for smart ring batteries

1 Ultra-Thin Curved Cell Design

Our curved polymer batteries are engineered to fit within narrow circular ring cavities — expertly balancing thickness, capacity, and durability for wearable devices.

2 Low Self-Discharge Chemistry

Optimized chemistry supports longer standby times and continuous data logging, reducing the frequency of charging cycles.

3 Consistent Mass-Production Performance

We maintain tight capacity and performance tolerances across production batches — essential for quality and reliability in wearable products.

This short video highlights how our curved polymer batteries are manufactured under controlled processes to ensure consistency and reliability.

Part 5. R&D support for smart ring battery development

Ufine Battery offers comprehensive engineering support across your product lifecycle:

- Tailored battery design based on your ring’s industrial form factor

- Prototype development and rapid iteration

- Integration guidance for charging system compatibility

- Collaborative testing support during hardware QA

Our team works closely with product engineers to ensure your smart ring power system meets design, performance, and safety expectations.

Part 6. Typical smart ring battery use cases

| Ufine Curved Battery Models | |||||||

|---|---|---|---|---|---|---|---|

| Model | Length*Width*Thickness (mm) | Nominal Capacity | Cycle Life | Nominal Voltage | Charging Voltage | Weight | Application |

| 150732 | 31.5*7*1.5 | 20mAh | 300 cycles | 3.7 V | 4.2 V | 0.52g | High-drain wearable features |

| 156825 | 25*6.9*1.5 | 16mAh | 300 cycles | 3.7 V | 4.2 V | 0.43g | Basic health tracking |

| 160630 | 30.8*6.2*1.6 | 18mAh | 300 cycles | 3.7 V | 4.2 V | 0.4g | Extended sensor suite |

Ufine Battery can customize capacity, voltage, curvature, and dimensions to meet your specifications — whether for prototype testing or volume production.

Find A Solution NowPart 7. Charging & power system compatibility

Smart rings often employ proprietary charging mechanisms such as magnetic contact pads, wireless docks, or compact adapters due to waterproof/sealed designs. Our batteries are engineered to:

- Integrate with low-current and optimized charge profiles

- Support magnetic, dock, and board-attached charging solutions

- Maintain stable performance under frequent charge cycles

This ensures a seamless hardware experience when integrating Li-Po power systems into your ring.

If you would like a practical overview of charging methods and best practices, you can also read our quick guide to smart ring battery charging

Part 8. Safety & reliability considerations

Battery safety and reliability are particularly important for wearable electronics where skin contact, temperature, and mechanical stress present additional risks. Ufine Battery addresses these concerns through:

- Stable electrolyte formulations

- Safety-aware packaging and mechanical stress mitigation

- Heat management strategies compatible with curved polymer cells

Proactive design reduces failure risks and improves long-term reliability — critical for user trust and product credibility.

Part 9. Certification & compliance support

Ufine Battery supports a wide range of battery and wearable device certifications tailored to your target markets and regulatory needs.

1 Battery-Level Certifications (Customizable)

We can assist with or deliver batteries compliant with:

- UN38.3 – Lithium battery transport compliance (mandatory for air shipment)

- MSDS / Safety Data Sheets – Chemical & safety documentation

- KC – Korea Certification (Korean domestic requirement)

- CE – EU conformity marking

- UL / CB Schemes – U.S. & international safety standards

- PSE – Japan Electrical Appliance Safety Law

- RoHS – Restriction of hazardous substances

2 Applicable Global Regulations & Standards

To support global product distribution, we help you navigate:

| Region / Country | Relevant Rules / Standards |

|---|---|

| United States | FCC + UL/ANSI safety test standards for electronics; OSHA guidelines;wearable battery standards (UL1642/UL62368-1) (UL Solutions) |

| European Union | CE Marking (EMC, LVD); RoHS Directive |

| Japan | PSE compliance for electronics |

| South Korea | KC Certification |

| International Shipping | UN38.3 for lithium battery – required for transport safety |

We also guide clients to official regulatory sources such as:

- UN38.3 battery transport guidelines — UNECE Transport of Dangerous Goods

- CE Directive listings — European Commission official site

- PSE/JP Electrical Appliance Safety Law via METI

For detailed information on our battery certifications and compliance support for global markets, please visit our battery certification overview

Part 10. From prototype to mass production

Ufine Battery supports a full product lifecycle, scaled to your project’s maturity:

- Low MOQ prototyping for early R&D

- Volume production with consistent quality assurance

- Buffer stock and supply continuity to maintain lead-time reliability

Part 11. Looking for a custom smart ring battery solution?

Whether you’re prototyping your first smart ring or scaling for global distribution, Ufine Battery provides customizable, curved polymer battery solutions engineered for performance, safety, and reliability.

Contact our engineering team today to discuss your battery design and compliance requirements.

High Energy Density

It stores large amounts of energy in a smaller and lighter package

Longer Cycle Life

Withstands extensive charge and discharge cycles

Low Self-Discharge

Maintains power longer when not in use

Safety

Minimizes the risk of accidents and ensures safe operation

More Information About Smart Ring Battery

it.

-

Why do smart rings use curved lithium polymer batteries instead of standard cells?

-

How long does it take to charge a smart ring battery?

-

Can smart ring batteries support fast charging?

-

What factors have the biggest impact on smart ring battery life?

-

What certifications are required to ship smart ring batteries internationally?

Latest Blogs

About Lithium Battery Industry News

Lithium-Ion vs Lead-Acid AMR & AGV Batteries Compared

Discover the pros and cons of lithium-ion and lead-acid AMR & AGV batteries. Learn about cost, lifespan, safety, and which is right for your fleet.

2026/01/14 Ufine

Robot Vacuum Battery Replacement: Easy Step-by-Step Guide

Learn how to replace a robot vacuum battery safely and easily. Step-by-step instructions, battery types, costs, and common mistakes to avoid.

2026/01/14 Ufine

Discover how to choose the right battery for your robot. Compare Li-ion, LiFePO₄, NiMH, and more for performance, safety, and cost.

2026/01/14 Ufine

Inside Humanoid Robot Battery Pack Design

A deep dive into humanoid robot battery pack design, covering battery life, voltage, capacity, safety, and real-world engineering trade-offs.

2026/01/14 Ufine

Humanoid Robot Battery Life: How Long Do They Really Last?

Most humanoid robots run 1.5–4 hours per charge. Learn real-world battery life, battery types, capacity limits, and future improvements.

2026/01/13 Ufine

Battery Load Test: A Comprehensive Guide

Step-by-step battery load test guide for car, solar & industrial use. Learn how to load test a battery, interpret voltage charts, and avoid common mistakes.

2025/12/18 Ufine