- 1. AI & humanoid robot application scope

- 2. Market context: from experimental robots to scalable systems

- 3. Industry challenges in AI & humanoid robot power systems

- 4. Solution overview

- 5. Key engineering approaches

- 6. Common battery types for AI & humanoid robots

- 7. Scenario-driven power architectures

- 8. R&D support for AI & humanoid robot projects

- 9. Certifications & compliance

- 10. Discuss your AI & humanoid robot battery application

1. AI & humanoid robot application scope

AI and humanoid robots cover a broad and fast-evolving set of applications, each imposing distinct constraints on power system design:

- Humanoid robots with bipedal or multi-joint locomotion and dexterous manipulation

- Service robots operating in hospitality, healthcare, retail, and public environments

- Research and laboratory humanoid platforms used for AI and robotics development

- Companion and social robots designed for long-duration interaction

- AI-enabled mobile manipulation robots combining autonomous mobility with perception and control

Unlike traditional industrial robots, these systems prioritize compactness, balance, intelligent power management, and human-interaction safety—making battery integration significantly more complex.

2. Market context: from experimental robots to scalable systems

The commercialization of intelligent robots is accelerating, directly reshaping battery system requirements. The global market for mobile robots—including AGVs and AMRs—is projected to reach approximately USD 22 billion by 2030, driven by large-scale adoption in logistics automation and smart manufacturing. As deployments scale from pilot projects to fleet-level operations, power systems must support continuous duty cycles, predictable degradation behavior, and rapid servicing.

Within this broader market, autonomous mobile robots (AMRs) alone are forecast to grow from an estimated USD 5.27 billion in 2025 to over USD 25 billion by 2035. This transition places new emphasis on battery consistency, lifecycle reliability, and thermal stability across thousands of operating units rather than isolated prototypes.

At the same time, humanoid robots are moving beyond research environments. Industry analysts estimate that annual humanoid robot shipments could approach 1 million units by 2030 as AI capability improves and manufacturing costs decline. At this scale, battery systems must be engineered for repeatability, safety certification, and integration within tightly constrained mechanical and thermal envelopes.

This shift from experimental robotics to scalable deployment makes battery system engineering a central design challenge rather than a secondary component decision.

3. Industry challenges in AI & humanoid robot power systems

1 High Energy Density Within Severely Limited Space

Humanoid robots integrate actuators, sensors, cameras, control electronics, and AI processors into compact structures. Battery systems must deliver sufficient runtime without increasing size or compromising mechanical layout.

2 Dynamic Load Profiles and Peak Power Demand

Locomotion, grasping, jumping, and rapid posture correction generate sharp current spikes. Battery packs must sustain high transient loads while maintaining voltage stability for sensitive control and AI modules.

3 Weight Distribution and Balance Sensitivity

Battery mass and placement directly influence center of gravity and gait stability. Poor weight distribution can reduce locomotion efficiency and degrade control accuracy.

4 Thermal Interaction With AI Compute Modules

AI processors and motor drivers generate significant heat. When battery systems operate in close proximity, unmanaged thermal coupling accelerates aging and reduces reliability.

5 Safety in Human-Interactive Environments

Service and humanoid robots operate near people. Battery systems must emphasize thermal stability, structural protection, and controlled failure behavior to meet safety expectations and regulatory requirements.

4. Solution overview

Effective power solutions for intelligent robots require system-level design rather than standalone battery selection. A comprehensive approach typically includes:

- Power architecture design aligned with AI compute, actuation, and sensor loads

- Cell chemistry and configuration strategy balancing energy density, discharge capability, and safety

- Mechanical integration planning to optimize weight distribution and spatial constraints

- Battery management strategies compatible with dynamic, AI-driven power consumption

- Lifecycle and reliability modeling to support iterative development and scalable deployment

This methodology ensures the battery system operates as an integrated subsystem within the robot rather than an isolated component.

5. Key engineering approaches

1 Challenge: High Peak Currents During Joint Actuation

Low-resistance pack architectures and high-rate lithium cells support transient current spikes while maintaining voltage stability for control electronics.

2 Challenge: Complex Internal Geometry and Limited Space

Custom-shaped lithium polymer and modular battery designs enable integration into irregular cavities without sacrificing structural integrity.

3 Challenge: Thermal Accumulation Near AI Processors

Thermal pathways, spatial separation strategies, and controlled charge/discharge profiles reduce localized heat buildup and extend service life.

4 Challenge: Balance and Stability Constraints

Multi-module battery layouts allow flexible placement to maintain optimal center of gravity and locomotion stability.

6. Common battery types for AI & humanoid robots

| Battery Type | Chemistry | Energy Density | Discharge Capability | Thermal Stability | Typical Use Case | Cycle Life | Form Factor Flexibility |

|---|---|---|---|---|---|---|---|

| LiFePO₄ | Lithium Iron Phosphate | Medium | Medium–High | Excellent | Safety-focused humanoid robots | 2000–4000 | Moderate |

| Li-ion NMC | Nickel Manganese Cobalt | High | High | Good | High-energy humanoid platforms | 1000–2000 | Moderate |

| Li-ion NCA | Nickel Cobalt Aluminum | Very High | High | Moderate | High-load AI robotics | 1000–2000 | Limited |

| Li-ion Polymer | Li-ion (Pouch) | Medium–High | Medium | Good | Compact service and humanoid robots | 1000–2500 | Excellent |

| High-Rate Li-ion | Specialized Li-ion | Medium | Very High | Moderate | Actuator-intensive robots | 800–1500 | Moderate |

| Low-Temp Li-ion | Modified Li-ion | Medium | Medium | Good | Robots in variable environments | 1000–2000 | Moderate |

All battery types can be customized in voltage, capacity, discharge characteristics, and form factor to match specific robot architectures.

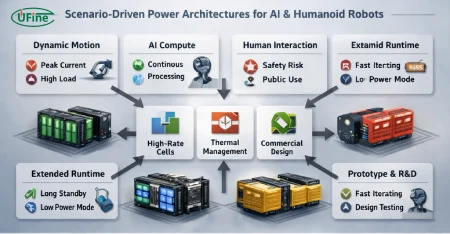

7. Scenario-driven power architectures

| Operating Scenario | Power Profile Characteristics | Key System Risks | Architecture & Engineering Strategy |

|---|---|---|---|

| Dynamic Locomotion & Actuation | Short-duration, high peak current during walking, lifting, and balance correction | Voltage sag, connector heating, actuator instability | High-rate lithium cells, parallel current paths, low-impedance bus design, peak-tolerant BMS current limits |

| AI Compute & Sensor Fusion | Continuous mid-to-high power draw with localized heat near processors | Thermal accumulation, voltage instability affecting compute reliability | Multi-rail power distribution, controlled discharge profiles, thermal isolation between battery and compute modules |

| Human Interaction & Service Operation | Moderate continuous load with frequent start-stop cycles | Safety risk in public environments, mechanical shock | Chemistries with higher thermal stability, modular energy segmentation, chassis-integrated protection, conservative fault detection |

| Extended Runtime & Standby Modes | Long idle periods combined with intermittent activity | Self-discharge, uneven cell aging | Low-leakage pack design, balanced cell selection, sleep-optimized BMS logic |

| Fleet Deployment & Commercial Use | Repetitive duty cycles across multiple robots | Inconsistent degradation, maintenance complexity | Modular or swappable battery architecture, matched cycle life to duty profile, batch-level consistency control |

| Prototype & R&D Iteration | Rapid configuration changes and varying load profiles | Over-engineering or mismatch with future production | Flexible pack layouts, scalable architectures, multi-round prototype validation aligned with production constraints |

AI and humanoid robots operate across highly diverse usage scenarios—ranging from intermittent human interaction to continuous autonomous motion—each imposing distinct electrical, mechanical, and thermal constraints on the power system. A scenario-driven power architecture aligns battery design with real operating conditions rather than nominal specifications, enabling predictable performance and system-level reliability.

1 Motion-Dominant Scenarios: Dynamic Actuation & Peak Load Control

In humanoid robots and mobile manipulation platforms, joint actuators generate short-duration but high-magnitude current peaks during walking, grasping, lifting, and posture correction. These transient loads often exceed average operating currents by several multiples, placing stress on both cells and interconnects.

- A scenario-driven architecture addresses this by:

- Selecting high-rate lithium cells optimized for low internal resistance

- Designing parallel cell configurations to distribute peak currents

- Minimizing voltage sag through low-impedance bus structures

- Coordinating BMS response to avoid unnecessary current limiting during motion events

This approach ensures stable actuator response without oversizing the entire battery system.

2 Compute-Intensive Scenarios: AI Processing & Sensor Fusion Loads

Advanced perception, navigation, and decision-making rely on AI processors, vision modules, and multi-sensor arrays that introduce sustained power draw with localized heat generation. Unlike motion loads, these demands are continuous and sensitive to voltage stability.

- Scenario-driven power architectures separate or isolate compute power paths by:

- Implementing multi-rail power distribution strategies

- Balancing energy density with thermal dissipation characteristics

- Managing charge and discharge profiles to reduce localized heating near processors

- This prevents thermal coupling between compute modules and energy storage, improving both system stability and battery longevity.

3 Human-Interactive Scenarios: Safety-First Energy Management

For service robots, companion robots, and humanoid platforms operating in close proximity to humans, battery safety extends beyond compliance—it becomes a functional requirement. Mechanical shock, unexpected contact, and partial enclosure designs introduce additional risk factors.

- Scenario-driven design incorporates:

- Cell chemistries with enhanced thermal stability

- Conservative energy segmentation using modular pack layouts

- Protective mechanical structures integrated with the robot chassis

- BMS logic tuned for abnormal condition detection and controlled shutdown

- These measures reduce the consequences of failure while maintaining usable energy density.

4 Deployment & Lifecycle Scenarios: Maintenance, Replacement, and Scaling

As AI and humanoid robots transition from prototypes to deployed fleets, power architecture must support maintainability and predictable aging behavior. Battery replacement cycles, charging logistics, and degradation patterns become operational considerations.

- A scenario-driven architecture supports deployment by:

- Designing modular or swappable battery assemblies

- Matching cycle life to expected duty profiles

- Enabling consistent performance across production batches

- Supporting fleet-level power management strategies

This reduces downtime and simplifies scaling from pilot programs to commercial rollout.

8. R&D support for AI & humanoid robot projects

AI and humanoid robot programs typically progress through multiple design iterations. Coordinated battery support across these stages reduces integration risk:

- Concept feasibility and power modeling

- Prototype battery design and lab validation

- Multi-round sample optimization

- Small-batch pilot production

- Transition to scalable mass production

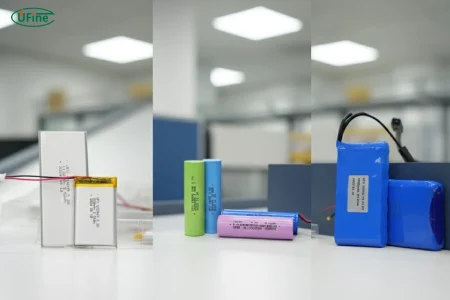

Leveraging in-house R&D and flexible production lines, Ufine Battery supports multi-round prototype iterations, small-batch pilot testing, and scalable volume production for complex AI-driven robotic systems.

Watch our production and engineering process in the video below.

9. Certifications & compliance

Battery systems for AI and humanoid robots must comply with international safety and transport standards:

- UN 38.3 – Lithium battery transportation safety

- IEC 62133 – Safety requirements for secondary batteries

- CE / UL – Regional safety and compliance standards

Early compliance planning is critical as humanoid robots move from R&D to commercial deployment.

For a complete list of certifications and compliance details, please visit our Certifications page.

10. Discuss your AI & humanoid robot battery application

As AI and humanoid robots scale toward real-world deployment, battery systems must be engineered for performance, safety, and manufacturability—not experimentation.

Ufine Battery has extensive experience engineering custom lithium battery systems—including Li-ion, LiFePO₄, and polymer cells—tailored to voltage, capacity, form factor, and discharge profiles for AI and humanoid robots.

Find Your Solution NowHigh Energy Density

It stores large amounts of energy in a smaller and lighter package

Longer Cycle Life

Withstands extensive charge and discharge cycles

Low Self-Discharge

Maintains power longer when not in use

Safety

Minimizes the risk of accidents and ensures safe operation

More Information About Humanoid Robot Battery

-

What battery chemistry is best for humanoid robots?

-

How do humanoid robots manage high peak current demands?

-

Can battery systems be modularized?

-

How is battery safety ensured in human-interactive robots?

Latest Blogs

About Lithium Battery Industry News

Lithium-Ion vs Lead-Acid AMR & AGV Batteries Compared

Discover the pros and cons of lithium-ion and lead-acid AMR & AGV batteries. Learn about cost, lifespan, safety, and which is right for your fleet.

2026/01/14 Ufine

Robot Vacuum Battery Replacement: Easy Step-by-Step Guide

Learn how to replace a robot vacuum battery safely and easily. Step-by-step instructions, battery types, costs, and common mistakes to avoid.

2026/01/14 Ufine

Discover how to choose the right battery for your robot. Compare Li-ion, LiFePO₄, NiMH, and more for performance, safety, and cost.

2026/01/14 Ufine

Inside Humanoid Robot Battery Pack Design

A deep dive into humanoid robot battery pack design, covering battery life, voltage, capacity, safety, and real-world engineering trade-offs.

2026/01/14 Ufine

Humanoid Robot Battery Life: How Long Do They Really Last?

Most humanoid robots run 1.5–4 hours per charge. Learn real-world battery life, battery types, capacity limits, and future improvements.

2026/01/13 Ufine

Battery Load Test: A Comprehensive Guide

Step-by-step battery load test guide for car, solar & industrial use. Learn how to load test a battery, interpret voltage charts, and avoid common mistakes.

2025/12/18 Ufine