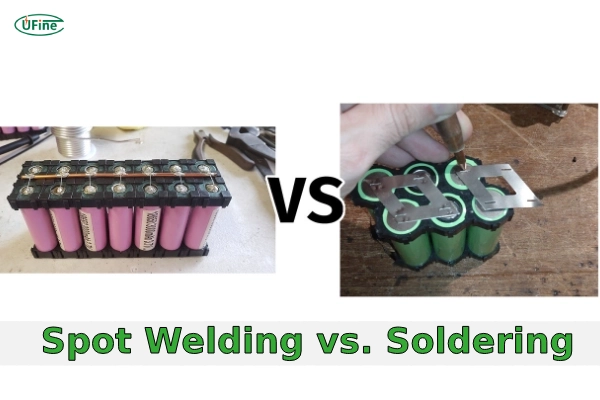

Spot welding fuses metal tabs using heat and pressure, providing fast, durable connections ideal for large-scale lithium battery manufacturing. In contrast, soldering melts a metal alloy to join parts, offering greater flexibility for DIY or small runs.

Battery spot welding creates strong bonds with minimal heat exposure, reducing risks to sensitive components and making it the preferred choice for high-volume, reliable battery packs.

Though both methods join battery parts effectively, their processes differ significantly. Spot welding relies on pressure and localized heat, while soldering uses melted filler metal. This guide will help you decide which technique suits your needs best.

Spot welding vs. soldering for lithium batteries: Spot welding uses heat and pressure to fuse metal tabs, making it faster and more durable for high-volume battery packs. Soldering melts a filler metal to join parts, offering flexibility for DIY and small-scale projects. For large-scale manufacturing, spot welding is usually preferred.

| Aspect | Spot Welding | Soldering |

|---|---|---|

| Speed | Very fast, ideal for mass production | Slower, better for small or custom projects |

| Bond Strength | Strong and durable | Moderate, can weaken under stress |

| Heat Impact | Minimal, protects battery cells | Higher heat, risk of damage if uncontrolled |

| Flexibility | Limited to accessible joints | Flexible, can reach tight spots |

| Equipment Cost | High initial investment | Lower, accessible for DIY use |

Part 1. Spot welding lithium batteries

What is Spot Welding?

Spot welding is a technique used to combine various lithium battery components. It uses electrical current to create a localized heat source, which melts and fuses the joined materials. Manufacturers commonly use this process in battery assembly due to its efficiency and effectiveness in building strong bonds.

Spot Welding Process

- Equipment: Spot welding machines have electrodes that apply pressure and conduct electricity to the battery components.

- Preparation: The battery components are cleaned and aligned before welding to ensure proper connection.

- Execution: We position the electrodes on either side of the components, then apply a high-current pulse to melt the materials and create a bond.

- Quality Control: Inspection of welds is essential to ensure the integrity and reliability of the battery pack.

How to Spot Weld Batteries: Step-by-Step

- Prepare materials – lithium cells, nickel strips, and a battery spot welder.

- Clean contact points – remove dirt and oxidation for better conductivity.

- Align nickel strip – position it on the cell terminals.

- Place electrodes – press firmly onto the strip at the welding point.

- Trigger weld – send a short, high-current pulse to fuse the strip.

- Inspect welds – ensure strong, consistent joints before use.

Advantages and Limitations of Spot Welding

Advantages:

- Speed: Spot welding is a rapid process suitable for high-volume production.

- Reliability: When performed correctly, spot welds provide strong and durable connections.

- Minimal Heat: Unlike other welding methods, spot welding generates minimal heat, reducing the risk of damaging sensitive battery components.

Limitations:

- Equipment Cost: Spot welding machines can be expensive to purchase and maintain.

- Skill Requirement: Proper execution of spot welding requires training and expertise to ensure consistent quality.

- Accessibility: Spot welding may not be suitable for joining components in hard-to-reach areas of the battery pack.

Part 2. Soldering lithium batteries

What is Soldering?

Soldering is a technique used to join components of lithium batteries by melting a filler metal, known as solder, and applying it to the connection point. This method provides an alternative to spot welding, offering different benefits and considerations.

Soldering Process

- Equipment: Soldering requires a soldering iron, solder wire, flux, and other tools for preparation and application.

- Preparation: We clean the battery components and may apply flux to promote adhesion.

- Application: The soldering iron is heated, and the solder wire is melted onto the joint, creating a bond as it solidifies.

- Cooling: The joint can cool and solidify fully after soldering before further handling.

Advantages and Limitations of Soldering

Advantages:

- Ease of Use: Many people consider soldering easier to learn and perform than spot welding, making it accessible to a broader range of users.

- Flexibility: Soldering allows for more flexibility in joining components, as it can reach areas that may be difficult to access with spot welding.

- Low Heat Impact: Unlike spot welding, soldering generates less heat during the process, reducing the risk of thermal stress and damage to sensitive battery components.

Limitations:

- Thermal Stress: Soldering can still subject the battery components to some degree of thermal stress, mainly if not performed correctly or if excessive heat is applied.

- Component Damage: Improper soldering technique or excessive heat can damage the battery components, reducing performance or safety risks.

- Skill Requirement: While soldering may be easier to learn initially, achieving consistently high-quality solder joints requires practice and skill development.

Part 3. Comparison between spot welding and soldering lithium batteries

When joining lithium battery components, manufacturers commonly use spot welding and soldering methods, each with advantages and limitations. Let’s delve into the comparison between these two techniques:

1. Speed and Efficiency

- Spot Welding: Due to its ability to create strong bonds quickly, manufacturers often prefer spot welding for high-volume production, thanks to its rapid process.

- Soldering: Soldering may take slightly longer than spot welding, as it involves melting solder onto the joint. Still, it offers more flexibility in terms of accessibility and ease of use.

2. Strength and Reliability

- Spot Welding: Spot welds generally provide strong and durable connections, making them suitable for applications where reliability is paramount.

- Soldering: While soldered joints can also be vital if performed correctly, they may not be as robust as spot welds and can be more susceptible to mechanical stress.

3. Heat Generation

- Spot Welding: Spot welding generates minimal heat during the process, reducing the risk of thermal stress to the battery components.

- Soldering: Soldering involves the application of heat to melt the solder, which can potentially subject the battery components to thermal stress if not carefully controlled.

4. Accessibility and Flexibility

- Spot Welding: Spot welding requires electrodes to be positioned directly on the joint, which may limit accessibility in specific configurations.

- Soldering: Soldering offers more flexibility in reaching difficult-to-access areas, making it suitable for joining components in complex battery pack designs.

5. Skill Requirement

- Spot Welding: While individuals require training and expertise to ensure proper execution and quality control in spot welding, they can master it with practice.

- Soldering: Many people generally consider soldering easier to learn and perform than spot welding, as it requires less specialized training and equipment.

6. Suitability for Battery Applications

- Spot Welding: Commonly used in large-scale battery manufacturing due to its speed and reliability.

- Soldering: Often preferred for smaller-scale production or custom battery designs where flexibility and accessibility are crucial.

| Aspect | Battery Spot Welding | Soldering |

|---|---|---|

| Process Speed | Very fast, suitable for high-volume production | Slower, better for custom or small-scale projects |

| Bond Strength | Highly durable and reliable | Moderate, can weaken under mechanical stress |

| Heat Impact | Minimal, reducing damage to sensitive components | Higher heat impact, requires careful control |

| Cost | Higher initial investment for equipment | Lower equipment cost, accessible for hobbyists |

| Flexibility | Limited to accessible joints | Can reach intricate and hard-to-access areas |

Part 4. Considerations for choosing the right method

1. Production Volume

- Large-Scale Production: Spot welding may be more suitable due to its speed and efficiency if you manufacture high-volume lithium batteries.

- Small-Scale Production: For smaller production runs or custom designs, soldering offers greater flexibility and may be more cost-effective.

2. Design Complexity

- Intricate Designs: If your battery design involves intricate components or hard-to-reach areas, you may prefer soldering for its accessibility and flexibility.

- Simple Designs: For straightforward battery designs with easily accessible connection points, spot welding may suffice and offer quicker assembly.

3. Skill Level and Training

- Expertise: Spot welding requires specialized training and expertise to ensure consistent quality welds.

- Ease of Learning: Soldering is generally easier to learn and perform, making it suitable for those with minimal welding experience.

4. Equipment Cost and Maintenance

- Initial Investment: Spot welding equipment can be expensive but may offer long-term savings for large-scale operations.

- Affordability: Soldering equipment is generally more affordable, making it accessible to smaller businesses or hobbyists.

5. Heat Sensitivity of Components

- Temperature Sensitivity: Consider the heat tolerance of your battery components when choosing between spot welding and soldering.

- Minimizing Heat Impact: If your components are sensitive to heat, spot welding’s lower heat output may be preferable to soldering.

6. Quality and Reliability Requirements

- Durability: Assess the durability and reliability requirements of your battery application.

- Quality Control: Consider which method allows for more accessible quality control and inspection to ensure the integrity of the battery assembly.

7. Regulatory Compliance and Safety

- Safety Standards: Ensure your welding method complies with relevant safety regulations and standards.

- Risk Assessment: Evaluate potential risks of each method, such as thermal stress or mechanical damage to battery components.

8. Future Scalability and Adaptability

- Scalability: Consider how easily your welding method can scale with future production demands.

- Adaptability: Assess whether your chosen method allows easy adaptation to changes in battery design or manufacturing processes.

DIY & Small Business Tips

- DIY battery spot welder: Affordable kits and transformer-based builds let hobbyists make a spot welder at home.

- Best for small runs: DIY welders suit repairs or prototypes without high equipment investment.

- Safety first: Wear eye protection and avoid welding near flammable materials.

Part 6. FAQs about spot welding vs soldering for lithium batteries

Is spot welding better than soldering for lithium batteries?

Spot welding is generally better for large-scale production and offers strong, reliable bonds with minimal heat impact. Soldering is ideal for small-scale projects or custom designs.

What equipment is needed for battery spot welding?

You need a spot welding machine with electrodes, proper alignment tools, and quality inspection equipment to ensure strong welds.

Can I use soldering for all lithium battery connections?

Soldering is suitable for intricate designs or areas where spot welding cannot reach, but it may not provide the same strength and reliability as spot welding.

Can spot welding be used for all battery sizes?

Spot welding is suitable for most battery sizes, especially cylindrical and prismatic cells. However, the equipment and settings must be adjusted to accommodate different sizes and materials.

What are the limitations of soldering for lithium batteries?

Soldering may introduce excessive heat to the battery, potentially damaging it. Additionally, solder joints are less mechanically robust compared to spot welds, making them less ideal for high-stress applications.

How to make a DIY battery spot welder?

A DIY battery spot welder can be built using a transformer from a microwave oven or a ready-made kit. Add copper electrodes, a foot pedal switch, and proper insulation. Ensure all components can handle high current safely.

Is spot welding safe for 18650 batteries?

Yes, if performed correctly. Spot welding applies minimal heat, reducing the risk of damaging 18650 cells compared to prolonged soldering.

Part 5. Final words

When deciding between spot welding and soldering for lithium battery assembly, consider factors like production volume, design complexity, skill level, equipment cost, component sensitivity, safety, and scalability. You can choose your manufacturing needs best by weighing these considerations.

Related Tags:

More Articles

What are Watts and Watt Hours in Battery?

Understand watt vs watt-hour in batteries, how to calculate battery watt hours, and what Wh means for car batteries, devices, and energy storage.

A Complete Guide to the Best Batteries for Flashlights

Compare the best batteries for flashlights, including AA, AAA, 18650, 21700, CR123A. See which battery offers the best brightness, runtime, and reliability.

How Long Do Rechargeable AA Batteries Last?

How long do rechargeable AA batteries last? Compare NiMH and lithium AA lifespan, recharge cycles, key factors, and performance vs alkaline batteries.

How Much Current Can a 9V Battery Really Supply?

Discover how many amps a 9V battery can supply, its actual current output, discharge rate, and capacity for alkaline, lithium, and rechargeable 9V batteries.

12V STD vs 12V AGM: Meaning, Differences, and Which Is Better

Understand what STD and AGM batteries mean, their key differences, and which 12V battery fits your needs best in 2026.