- Part 1. Understanding hearing aid battery technology

- Part 2. Why lithium-ion batteries are ideal for modern hearing aids

- Part 3. Key features of custom lithium hearing aid battery designs

- Part 4. Customization options for OEM hearing aid manufacturers

- Part 5. Engineering challenges in custom lithium battery integration

- Part 6. Lithium vs zinc-air hearing aid batteries: A performance comparison

- Part 7. Regulatory standards for OEM lithium hearing aid batteries

- Part 8. Emerging trends in lithium hearing aid battery technology

- Part 9. How to select the best lithium battery for your hearing aid design

- Part 10. Partnering with the right custom lithium battery manufacturer

- Part 11. FAQs about hearing aid battery

What is a custom lithium hearing aid battery and why it matters for OEMs

A custom lithium hearing aid battery is a specially engineered energy solution designed to meet the specific requirements of hearing aid devices. For OEM (Original Equipment Manufacturer) developers, choosing the right battery is critical. It influences the device’s size, performance, life cycle, and most importantly, user satisfaction.

As hearing aids become smaller, smarter, and more connected, lithium battery technology has become the top choice. In this guide, we’ll explore how OEMs can design better hearing aids by leveraging custom lithium battery solutions.

Part 1. Understanding hearing aid battery technology

A hearing aid battery is a compact power unit used to operate hearing aids. It ensures the device functions effectively throughout the day. There are two major categories:

- Zinc-air batteries: These are disposable and activated by air.

- Lithium-ion batteries: These are rechargeable and reusable.

Most legacy hearing aids use zinc-air batteries. However, with increased power needs and user demands, lithium hearing aid batteries are now the preferred choice due to their efficiency, eco-friendliness, and rechargeability.

Part 2. Why lithium-ion batteries are ideal for modern hearing aids

OEMs designing modern hearing aids must prioritize power efficiency, form factor, and reliability. Lithium-ion batteries offer unmatched benefits:

- High energy density: Supports long usage times in a small package.

- Rechargeability: Saves users from replacing batteries every few days.

- Stable output: Delivers consistent voltage to prevent audio distortion.

- Support for smart features: Enables Bluetooth, AI, and noise cancellation.

- Eco-friendly: Reduces waste compared to disposable options.

These advantages make custom lithium batteries the go-to solution for premium hearing aid models.

Part 3. Key features of custom lithium hearing aid battery designs

When OEMs create custom lithium batteries for hearing aids, several design features must be considered:

- Form factor flexibility: Batteries can be designed to fit ultra-compact shells.

- Voltage and capacity control: Tailored to suit the device’s power needs.

- Fast charging capability: Enables full charge in under 4 hours.

- Cycle life: Premium models offer up to 500-1000 charge cycles.

- Thermal management: Keeps the battery cool during use and charge.

- Integrated protection circuits: Guards against overcharge, short circuits, and overheating.

Custom lithium batteries allow brands to optimize device performance without compromising on size or safety.

Part 4. Customization options for OEM hearing aid manufacturers

OEMs have several customization opportunities when designing lithium hearing aid batteries:

- Cell shape and size: Coin cell, prismatic, or pouch cells depending on product design.

- Nominal voltage settings: Typically between 3.6V to 3.8V, depending on device needs.

- Battery capacity: Ranging from 15mAh to 100mAh for hearing aids.

- Connector type: Custom terminals or integrated PCBs for smart charging.

- Branding and packaging: OEMs can include logos, QR codes, and serials.

These options allow manufacturers to build high-performance, brand-specific power solutions that meet both design and technical goals.

Part 5. Engineering challenges in custom lithium battery integration

Designing custom lithium batteries for hearing aids is complex. OEMs face several challenges:

- Miniaturization: Fitting powerful batteries into small form factors.

- Battery safety: Ensuring the battery doesn’t overheat or leak.

- Durability: Maintaining performance over hundreds of charge cycles.

- User behavior: Accounting for daily usage and charging habits.

- Regulatory compliance: Adhering to international safety and quality standards.

Overcoming these obstacles requires collaboration with experienced battery manufacturers and engineers who understand the hearing aid industry.

Part 6. Lithium vs zinc-air hearing aid batteries: A performance comparison

Choosing between lithium-ion and zinc-air batteries depends on the product’s purpose, user expectations, and market segment. Below is a real-world comparison based on manufacturer data and user feedback:

| Feature | Lithium-Ion Battery | Zinc-Air Battery |

|---|---|---|

| Rechargeability | Yes | No |

| Typical lifespan | 2 to 3 years (500-1000 cycles) | 5 to 12 days (single use) |

| Energy density | ~300 Wh/L | ~100 Wh/L |

| Operating voltage | 3.6V – 3.8V | 1.4V |

| Environmental impact | Low (recyclable, fewer disposables) | High (frequent replacements) |

| Cost per year (est.) | ~$30-$50 (charger included) | ~$100-$150 (replacing batteries weekly) |

| Size flexibility | High (custom shapes possible) | Limited to standard sizes |

| Best for | Premium, rechargeable models | Budget, disposable models |

Summary

Lithium-ion batteries clearly outperform zinc-air batteries in efficiency, long-term cost, and environmental impact. While zinc-air may suit low-cost hearing aids, lithium is a superior choice for advanced, feature-rich devices. OEMs aiming for durability and innovation should prioritize lithium designs.

Part 7. Regulatory standards for OEM lithium hearing aid batteries

OEMs must meet several global standards to ensure product safety and market access:

- UN38.3: Safe transport of lithium batteries by air or sea.

- IEC 62133: International safety standard for rechargeable cells.

- RoHS: Restriction of hazardous substances (EU compliance).

- ISO 9001: Quality management system certification.

- CE and FDA: Required for sales in Europe and the US respectively.

Failure to comply can lead to legal issues, product recalls, and brand damage. OEMs should partner with battery suppliers who provide full documentation and testing.

Part 8. Emerging trends in lithium hearing aid battery technology

The battery industry is evolving fast, especially in the medical device sector. Here are the top trends OEMs should watch:

- Solid-state lithium batteries: Offering higher energy density and safety.

- Faster wireless charging: Enabled by new charging protocols and smart docks.

- Battery health monitoring: Real-time diagnostics using smart chips.

- Eco-conscious manufacturing: Using recyclable or biodegradable materials.

- Flexible battery designs: Conforming to ergonomic shapes for better fit.

OEMs that embrace these innovations early will lead the market in comfort, performance, and sustainability.

Part 9. How to select the best lithium battery for your hearing aid design

Choosing the right battery is more than matching specs. Follow this step-by-step approach:

- Define power needs: Based on audio amplification, Bluetooth, and AI features.

- Determine space limits: Use 3D models to match battery dimensions.

- Set performance goals: Decide on usage hours per charge and target recharge cycles.

- Choose a battery type: Coin cell, pouch, or custom-shaped lithium.

- Ensure safety compliance: Include protection circuits and certifications.

- Prototype and test: Use real-world simulations and user trials.

- Evaluate suppliers: Look for partners with medical device experience and ISO certification.

A well-chosen battery enhances product quality and brand trust, while minimizing user complaints and returns.

Part 10. Partnering with the right custom lithium battery manufacturer

OEMs often lack the internal resources for battery R&D. That’s why choosing the right partner is critical. Look for these qualities:

- Experience in medical-grade lithium batteries

- In-house engineering and prototyping

- Support for low and high-volume production

- Compliance with global standards

- Custom packaging and private labeling options

A strong battery supplier can help OEMs reduce time-to-market, manage costs, and deliver high-quality products that meet user expectations.

Part 11. FAQs about hearing aid battery

How long does a lithium hearing aid battery last?

A lithium hearing aid battery can last 24 to 36 hours per charge and withstand up to 1000 recharge cycles, which equates to 2-3 years of daily use.

Are lithium hearing aid batteries safe?

Yes. Custom lithium batteries for hearing aids include multiple safety features, such as thermal protection, overcharge prevention, and short-circuit control. They must also pass strict international safety tests.

Can lithium batteries be custom-shaped for hearing aids?

Absolutely. Unlike zinc-air batteries, lithium batteries can be molded or layered to fit unique hearing aid designs, including in-ear and behind-the-ear models.

What makes lithium batteries better than zinc-air for hearing aids?

Lithium batteries are rechargeable, longer-lasting, and more eco-friendly. Zinc-air batteries are disposable and less suitable for modern digital features and wireless connectivity.

What certifications are needed for lithium batteries in hearing aids?

Key certifications include IEC 62133, UN38.3, RoHS, and ISO 9001. For USA and EU markets, FDA and CE approvals are also essential.

Related Tags:

More Articles

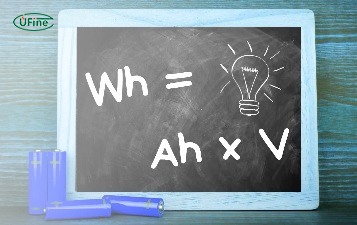

What are Watts and Watt Hours in Battery?

Understand watt vs watt-hour in batteries, how to calculate battery watt hours, and what Wh means for car batteries, devices, and energy storage.

A Complete Guide to the Best Batteries for Flashlights

Compare the best batteries for flashlights, including AA, AAA, 18650, 21700, CR123A. See which battery offers the best brightness, runtime, and reliability.

How Long Do Rechargeable AA Batteries Last?

How long do rechargeable AA batteries last? Compare NiMH and lithium AA lifespan, recharge cycles, key factors, and performance vs alkaline batteries.

How Much Current Can a 9V Battery Really Supply?

Discover how many amps a 9V battery can supply, its actual current output, discharge rate, and capacity for alkaline, lithium, and rechargeable 9V batteries.

12V STD vs 12V AGM: Meaning, Differences, and Which Is Better

Understand what STD and AGM batteries mean, their key differences, and which 12V battery fits your needs best in 2026.