- Part 1. What is a 12V 12Ah lithium ion battery?

- Part 2. Why are custom battery packs important for industrial equipment?

- Part 3. How does a 12V 12Ah lithium ion battery work?

- Part 4. What are the advantages of 12V 12Ah lithium ion batteries in industrial applications?

- Part 5. What types of industrial equipment use 12V 12Ah lithium ion battery packs?

- Part 6. How to design a custom 12V 12Ah lithium ion battery for industrial use?

- Part 7. What safety features are essential for industrial battery packs?

- Part 8. How does a 12V 12Ah lithium ion battery compare to other industrial battery types?

- Part 9. How to maintain a custom 12V 12Ah lithium ion battery for industrial use?

- Part 10. How to choose a custom lithium ion battery supplier for industrial applications?

- Part 11. FAQs about 12V 12Ah lithium ion battery

What is a 12V 12Ah lithium ion battery pack and why is it the best solution for powering industrial equipment?

A custom 12V 12Ah lithium ion battery is a high-efficiency, rechargeable battery system tailored to meet the power needs of industrial machines. These batteries deliver stable voltage, long cycle life, and outstanding energy density, making them ideal for use in robots, sensors, surveillance systems, forklifts, and mobile medical devices. In industrial settings where performance, safety, and uptime matter most, these custom battery packs deliver a reliable and intelligent power source. This article offers a deep dive into the structure, advantages, applications, and selection process of custom 12V 12Ah lithium ion batteries, helping you understand why they outperform traditional options.

Part 1. What is a 12V 12Ah lithium ion battery?

A 12V 12Ah lithium ion battery is a rechargeable energy storage device that supplies 12 volts of power and a total capacity of 12 ampere-hours. It belongs to a class of lightweight, high-performance batteries that use lithium-ion chemistry to store and release electrical energy.

Key specifications:

- Nominal Voltage: 12.8V (4 cells x 3.2V for LiFePO4)

- Capacity: 12Ah

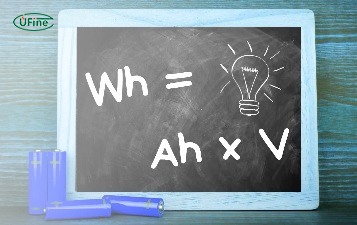

- Energy: 153.6Wh

- Chemistry: LiFePO4 or NMC

- Cycle Life: 2000–5000 cycles

- Weight: ~1.5–2.2 kg (depending on case and BMS)

Unlike SLA (sealed lead-acid) batteries, these lithium ion batteries hold charge longer, charge faster, and last significantly more cycles, making them ideal for industrial-grade applications.

Part 2. Why are custom battery packs important for industrial equipment?

Industrial machinery has unique electrical and mechanical requirements that off-the-shelf batteries often fail to meet. A custom 12V 12Ah lithium ion battery pack is built specifically for a product or application, ensuring better compatibility, durability, and performance.

Benefits of customization:

- Exact fit for enclosures

- Optimized voltage and capacity

- Tailored BMS settings

- Environmental protection (IP-rated enclosures)

- Customized connectors and wiring

These advantages reduce downtime, increase system efficiency, and eliminate the risk of battery-related failures in mission-critical scenarios.

Part 3. How does a 12V 12Ah lithium ion battery work?

Lithium ion batteries operate through reversible electrochemical reactions between the anode and the cathode. When discharging, lithium ions flow from the anode (usually graphite) to the cathode (often lithium iron phosphate or nickel-based oxide), releasing electrons that provide electric current.

Main components:

- Cells: 4 LiFePO4 cells in series (for 12.8V)

- BMS: Battery Management System for safety

- Protection Circuit: Prevents overcharging, short circuits

- Enclosure: Industrial-grade casing for durability

Charging reverses the ion flow, pushing lithium ions back into the anode. The BMS controls voltage balancing, thermal management, and state-of-charge estimation to maintain safety and extend battery life.

Part 4. What are the advantages of 12V 12Ah lithium ion batteries in industrial applications?

1. Extended cycle life

- These batteries can last up to 10 years with 2000–5000 cycles depending on usage and charge-discharge rates.

2. High energy efficiency

- Efficiency levels reach 96–98%, reducing energy waste and operating costs.

3. Lightweight design

- At around 1.8 kg, they are much lighter than lead-acid equivalents, improving portability and machine ergonomics.

4. Fast charging

- Typical charge time is 2–4 hours, compared to 8–12 hours for lead-acid batteries.

5. Minimal maintenance

- No need for electrolyte replacement or equalizing charges.

6. Stable voltage output

- Power remains consistent even under heavy loads, which is vital for motors, sensors, and automation systems.

Part 5. What types of industrial equipment use 12V 12Ah lithium ion battery packs?

These battery packs are versatile and used across dozens of industries:

- Mobile medical equipment: infusion pumps, portable X-rays, surgical carts

- Robotics and automation: AGVs, warehouse bots, robotic arms

- Agricultural machinery: soil sensors, GPS devices, power units

- Surveillance systems: remote cameras, solar security units

- Telecommunication: portable transceivers, signal repeaters

- Construction equipment: laser levels, GPS trackers

- Marine and RV systems: navigation units, lighting

Their compact form factor, high energy density, and smart electronics make them a go-to choice for rugged and remote environments.

Part 6. How to design a custom 12V 12Ah lithium ion battery for industrial use?

Designing a custom battery means tailoring it to a specific power profile and environment. The process includes:

- Define electrical requirements: Peak current, continuous load, voltage, runtime

- Choose cell chemistry:

- LiFePO4: safer, longer lifespan

- NMC: higher energy density, more compact

- Decide on cell configuration:

- 4S1P for 12V 12Ah

- 4S2P for 12V 24Ah

- Add a smart BMS: Include over-voltage, under-voltage, current limiters, temperature sensors

- Design the enclosure: Consider IP rating, vibration resistance, and thermal management

- Testing and validation: Simulate real-world use to check thermal performance, EMI, and lifecycle

A well-designed custom battery boosts performance, lowers downtime, and extends equipment life.

Part 7. What safety features are essential for industrial battery packs?

Safety is a top priority in industrial environments. A 12V 12Ah lithium ion battery must include:

- Overcharge protection: Prevents voltage from exceeding safe limits

- Over-discharge protection: Stops operation when voltage drops too low

- Short circuit protection: Cuts off current if a direct connection occurs

- Overcurrent protection: Prevents damage from excessive current draw

- Thermal cutoff: Shuts down if temperature exceeds threshold

- Cell balancing: Ensures even charge distribution among cells

- Fire-resistant casing: Limits damage in hazardous environments

These measures are managed by the Battery Management System, which acts as the brain of the battery.

Part 8. How does a 12V 12Ah lithium ion battery compare to other industrial battery types?

Below is a data-driven comparison between 12V 12Ah batteries of different chemistries, based on real-world industrial use and manufacturer specifications:

| Feature | LiFePO4 (Lithium Ion) | SLA (Lead-Acid) | NiMH |

|---|---|---|---|

| Nominal Voltage | 12.8V | 12V | 12V |

| Typical Weight | 1.8 kg | 4.0 – 4.5 kg | 3.5 – 4.0 kg |

| Cycle Life | 3000 – 5000 | 300 – 500 | 500 – 800 |

| Energy Efficiency | 96 – 98% | 70 – 80% | 65 – 75% |

| Charge Time (80%) | 1.5 – 2 hours | 6 – 10 hours | 3 – 6 hours |

| Self-discharge per month | <3% | 15 – 20% | 20 – 30% |

| Maintenance | No | Yes | Low |

| Temperature Range | -20°C to 60°C | 0°C to 40°C | 0°C to 45°C |

Summary:

The 12V 12Ah LiFePO4 battery offers the longest lifespan, least maintenance, and highest efficiency. While SLA batteries are cheaper upfront, they require frequent replacement and maintenance. NiMH batteries are more stable than SLA but fall behind lithium in energy density and charge speed. In industrial use cases where durability and performance matter, LiFePO4 batteries are the superior choice.

Part 9. How to maintain a custom 12V 12Ah lithium ion battery for industrial use?

Proper maintenance ensures long service life and safe operation:

- Charge regularly: Avoid deep discharge below 10%

- Use the correct charger: Match voltage and current ratings

- Avoid extreme temperatures: Store between 10°C and 30°C

- Perform periodic inspections: Check for swelling, corrosion, or abnormal heat

- Keep firmware updated: If BMS has a software interface, update periodically

Avoiding misuse and following these steps can extend battery life by several years.

Part 10. How to choose a custom lithium ion battery supplier for industrial applications?

Choosing the right supplier is as important as choosing the right battery chemistry. Look for:

- Experience with industrial projects

- ISO 9001 and ISO 14001 certifications

- In-house testing and prototyping

- Customized BMS development

- Compliance with UN38.3, CE, RoHS

- After-sales support and documentation

Ask for engineering drawings, technical datasheets, and sample units before ordering in bulk.

Part 11. FAQs about 12V 12Ah lithium ion battery

What are the advantages of using a custom 12V 12Ah lithium ion battery in automated warehouse robots?

Custom 12V 12Ah lithium ion batteries are ideal for warehouse robots due to their lightweight design, high energy output, and fast charging capabilities. They fit seamlessly into compact robotic frames and support continuous operation with minimal downtime.

How long can a 12V 12Ah lithium ion battery power a remote surveillance camera system?

A 12V 12Ah battery can power a typical 10W surveillance system for about 14–16 hours, depending on conditions. For solar-powered setups, the battery serves as a reliable backup during cloudy days or nighttime.

Is a 12V 12Ah lithium ion battery suitable for solar agricultural IoT devices?

Yes. These batteries are perfect for solar irrigation controllers, weather sensors, and soil moisture monitors. Their low self-discharge rate (<3% per month) ensures consistent power even with intermittent sunlight.

Can I integrate a custom 12V 12Ah lithium ion battery into a portable medical device?

Absolutely. Medical device manufacturers often use custom 12V 12Ah packs for infusion pumps, diagnostic tools, and portable imaging systems due to their stable output and medical-grade safety features.

How do I select the best BMS for a 12V 12Ah lithium ion battery used in construction tools?

For rugged power tools, choose a BMS with overcurrent protection, thermal cutoff, and vibration resistance. It should support peak loads and provide real-time diagnostics to avoid tool failure on-site.

Related Tags:

More Articles

What are Watts and Watt Hours in Battery?

Understand watt vs watt-hour in batteries, how to calculate battery watt hours, and what Wh means for car batteries, devices, and energy storage.

A Complete Guide to the Best Batteries for Flashlights

Compare the best batteries for flashlights, including AA, AAA, 18650, 21700, CR123A. See which battery offers the best brightness, runtime, and reliability.

How Long Do Rechargeable AA Batteries Last?

How long do rechargeable AA batteries last? Compare NiMH and lithium AA lifespan, recharge cycles, key factors, and performance vs alkaline batteries.

How Much Current Can a 9V Battery Really Supply?

Discover how many amps a 9V battery can supply, its actual current output, discharge rate, and capacity for alkaline, lithium, and rechargeable 9V batteries.

12V STD vs 12V AGM: Meaning, Differences, and Which Is Better

Understand what STD and AGM batteries mean, their key differences, and which 12V battery fits your needs best in 2026.