Part 1. Lithium Battery Components

-

1. Battery Structure

Lithium batteries operate on the principle of electrochemical reactions between the anode and cathode through a medium known as the electrolyte. A typical lithium battery consists of:

- a. Anode (negative electrode): Releases electrons during discharge.

- b. Cathode (positive electrode): Accepts electrons during discharge.

- c. Electrolyte: Facilitates lithium-ion movement between electrodes.

- d. Separator: Prevents direct contact between the anode and cathode while allowing ion flow.

-

2. Functional Principle

When the battery is charged, lithium ions move from the cathode to the anode. During discharge, the ions travel back to the cathode, producing an electric current.

Learn About the Cathode and Anode of the Battery

Part 2. Lithium Battery Materials

-

High-quality materials are the foundation of reliable battery performance. The selection of materials significantly affects energy density, cycle life, safety, and cost.

1. Positive Electrode Materials

Common cathode materials include:

- a. Lithium Cobalt Oxide (LiCoO₂): High energy density, used in consumer electronics.

- b. Lithium Iron Phosphate (LiFePO₄): Superior thermal stability, long cycle life.

- c. Lithium Nickel Manganese Cobalt (NMC): Balanced performance, often used in EVs.

-

2. Negative Electrode Materials

- a. Graphite: The most widely used anode material for its stability and high conductivity.

- b. Silicon-graphite composites: Offer higher capacity but come with expansion challenges.

-

3. Separator

The separator is a porous membrane, typically made of polyethylene (PE) or polypropylene (PP), designed to allow ion flow while preventing short circuits.

-

4. Electrolyte

The electrolyte is typically a lithium salt (like LiPF₆) dissolved in a mix of organic solvents such as ethylene carbonate and dimethyl carbonate, enabling efficient ion transport.

Part 3. What Is the Lithium Battery Production Process?

-

The lithium battery production process involves multiple highly controlled and automated steps to ensure safety and performance. The key stages are:

- Step 1. Electrode Preparation: Active materials are mixed with binders and conductive additives to form a slurry, which is coated onto metal foils (aluminum for cathodes, copper for anodes).

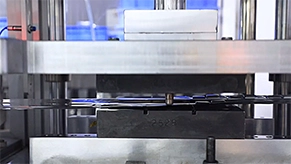

- Step 2. Drying and Calendaring: The coated electrodes are dried to remove solvents and then compressed to uniform thickness.

- Step 3.Electrode Slitting: Electrodes are cut into desired widths to fit cell formats.

- Step 4. Cell Assembly: The electrodes are stacked or wound with separators in pouch, cylindrical, or prismatic forms.

- Step 5.Electrolyte Filling: The cells are vacuum-sealed and filled with electrolyte in a moisture-controlled environment.

- Step 6. Formation and Aging: The cells are charged and discharged under controlled conditions to activate materials and stabilize performance.

- Step 7. Testing and Grading: Each cell undergoes rigorous testing to ensure capacity, voltage, impedance, and safety before packaging.

Part 4. What Are the Lithium Battery Types?

-

There are several types of lithium batteries, each optimized for specific use cases:

- 1. Lithium Polymer (LiPo): Lightweight, flexible shapes, commonly used in drones, wearables, and smartphones.

- 2. Lithium Iron Phosphate (LiFePO₄): Excellent safety and long life, ideal for energy storage systems and electric vehicles.

- 3. 18650 and Cylindrical Cells: High energy density and standard sizes, widely used in power tools and battery packs.

- 4. Ultra-thin and Shaped Batteries: Designed for slim or uniquely shaped applications such as smart cards or IoT devices.

Part 5. How Is Lithium Cell Manufactured?

-

Lithium cells are the building blocks of battery packs. The lithium cell production process includes:

- a. Jelly Roll/Winding or Stacking: Electrode sheets are assembled in a specific configuration.

- b. Tab Welding: Tabs are welded to the electrodes for current collection.

- b. Sealing: Cells are sealed in aluminum or steel casing (cylindrical or prismatic) or laminated pouches (polymer).

- d. Electrolyte Injection & Sealing: The electrolyte is injected, and cells are hermetically sealed.

- e. Formation Cycling: Cells are cycled several times to stabilize performance.

- f. Final Testing: Cells are tested for capacity, voltage, resistance, and leakage.

Step 1: Pole piece production

Step 2: Battery Cell Production

Step 3: Battery Cell Assembly

Part 6. How to Make a Lithium Battery Pack?

-

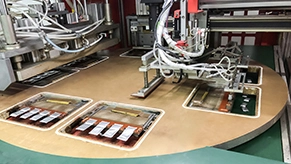

Once individual cells are produced and tested, they are integrated into battery packs. The battery pack production process includes:

- a. Cell Matching and Grouping: Cells are matched by capacity and voltage to ensure consistent performance.

- b. Battery Management System (BMS) Integration: A BMS monitors charge/discharge cycles, balancing, temperature, and safety protections.

- c. Mechanical Design and Assembly: The cells are housed in protective enclosures with wiring, PCBs, insulation, and connectors.

- d. Final Testing: The finished battery packs are tested for performance, durability, safety, and environmental resistance.

Step 4: Battery Pack

Part 7. Ufine Battery Solutions

-

Our Products

Ufine Battery is a trusted Chinese custom lithium battery manufacturer, serving global clients with tailor-made energy solutions. We offer a wide range of high-performance lithium batteries, including:

- a. Lithium Polymer (LiPo) Batteries

- b. LiFePO₄ Batteries

- c. 18650 and Cylindrical Lithium Batteries

- d. Ultra-thin and Shaped Batteries

- f. High-rate and High/Low Temperature Batteries

-

Customization

We support full customization based on your specifications—including voltage, capacity, size, shape, and discharge rate—to meet diverse application requirements in IoT, robotics, medical, industrial, and consumer electronics sectors.

Whether you need a unique form factor, a high-drain solution, or enhanced thermal performance, Ufine Battery is your reliable partner in the lithium battery production process. Our advanced facilities and experienced engineering team ensure high efficiency, safety, and performance in every project.

Contact Ufine Battery today to learn more about our lithium battery manufacturing capabilities and start your custom battery solution.

Battery Production Equipment

Battery Laboratory

Battery Making Machine

- 1. Capacity

- 2. Charge Recovery

- 3. Charge Retention

- 4. Charging Rate

- 5. Discharge Capacity

- 1. External short circuit test

- 2. Crush test

- 3. Impact test

- 4. Nail penetration test

- 5. Other safety test

- 1. Density

- 2. Viscosity

- 3. Melting Point

- 4. Boiling Point

Related Articles