Lithium-ion battery packs have become integral to various industries due to their unique properties. This article delves into the composition, working mechanism, types, benefits, and frequently asked questions surrounding these essential power sources.

Part 1. Lithium-ion battery pack

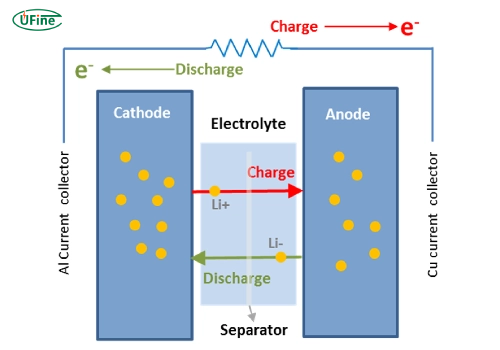

Battery components

Cathode:

The cathode, a crucial component in lithium-ion battery packs, typically comprises lithium cobalt oxide (LiCoO2), lithium iron phosphate (LiFePO4), or other lithium-based compounds. It acts as the source of positively charged ions during the battery’s operation.

Anode:

The anode, often made of graphite or other carbon-based materials, functions as the receptacle for lithium ions during charging. It releases these ions during discharging, facilitating the flow of electrons through the external circuit.

Separator:

A separator, usually a microporous polymer membrane, physically separates the cathode and anode while allowing the passage of lithium ions. It prevents short circuits by inhibiting direct contact between the two electrodes.

Electrolyte:

The electrolyte is a conductive solution that facilitates the movement of lithium ions between the cathode and anode. It can be a liquid, gel, or solid polymer, ensuring the ion transport necessary for the battery’s functionality.

Outer Casing:

The outer casing, typically made of aluminum or steel, encloses the battery components, providing structural support, protection against physical damage, and insulation to prevent leakage.

Part 2. How does a battery work?

Lithium-ion battery packs operate through an intricate electrochemical process involving the movement of ions and electrons. The charging and discharging cycle is as follows:

1. Charging:

During charging, an external power source applies a voltage to the battery. This voltage prompts lithium ions to move from the cathode to the anode through the electrolyte, where they are stored within the anode material.

2. Discharging:

When the battery powers a device, the stored lithium ions move back from the anode to the cathode through the electrolyte. This movement releases electrons, creating an electric current that powers the connected device.

3. Ion movement and electron flow:

As the lithium ions shuttle back and forth between the electrodes, the electron flow completes the circuit, allowing for the continuous generation of electrical energy.

4. Reversible:

This electrochemical process is reversible, enabling multiple charging and discharging cycles without significant degradation of the battery’s performance, making lithium-ion battery packs highly efficient and durable.

Part 3. Lithium-ion battery pack types

Common types

Cylindrical cells:

Cylindrical lithium-ion cells, such as 18650 and 21700, have a cylindrical shape and are prevalent in consumer electronics like laptops, power tools, and flashlights due to their ease of manufacture and reliability.

Prismatic cells:

Prismatic lithium-ion cells have a flat, rectangular shape and are often used in smartphones, tablets, and other compact devices where space optimization is crucial. They offer flexibility in design and are relatively safer due to their sturdy packaging.

Pouch cells:

Pouch lithium-ion cells are thin, flexible, and lightweight, making them suitable for applications requiring custom shapes or sizes. These cells find use in wearables, electric vehicles (EVs), and various portable electronics.

High-capacity and specialized packs

High-capacity packs:

Battery packs with higher energy densities are developed to cater to devices requiring extended usage periods without frequent recharging. They are used in electric vehicles, large-scale energy storage systems, and high-performance electronics.

Specialized packs for EVs and energy storage:

Lithium-ion battery packs for electric vehicles and energy storage systems undergo specialized engineering to meet high power and capacity demands. These packs often employ advanced thermal management and safety features to ensure reliable performance.

Part 4. Lithium-ion battery pack combination

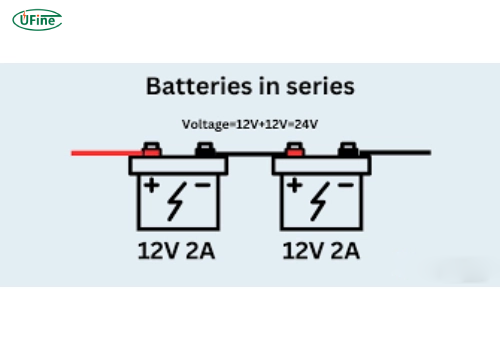

Lithium-ion battery Series Configuration

Increased voltage:

Series configuration involves connecting multiple lithium-ion cells in a sequence, end-to-end, to increase the total voltage output. This setup is common in electric vehicles and high-voltage applications, where higher voltage levels are required.

Voltage addition:

For instance, if two 3.7-volt cells are connected in series, the total voltage output would be 7.4 volts. This addition of individual cell voltages results in a higher combined voltage output for the overall battery pack.

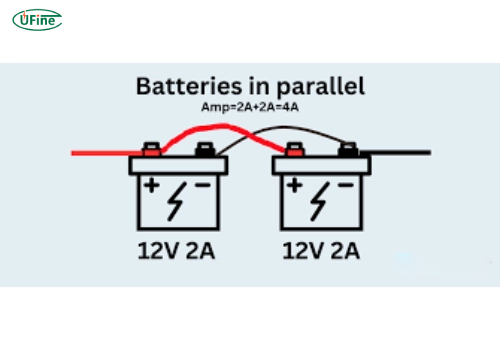

Lithium-ion battery Parallel Configuration

Enhanced capacity:

Parallel configuration involves connecting cells side-by-side to increase the overall capacity of the battery pack. It’s beneficial for applications where longer runtime or higher energy capacity is essential.

Capacity addition:

Connecting two cells with the same voltage and capacity in parallel effectively doubles the capacity while maintaining the same voltage output. For example, two 3000mAh cells in parallel would result in a total capacity of 6000mAh.

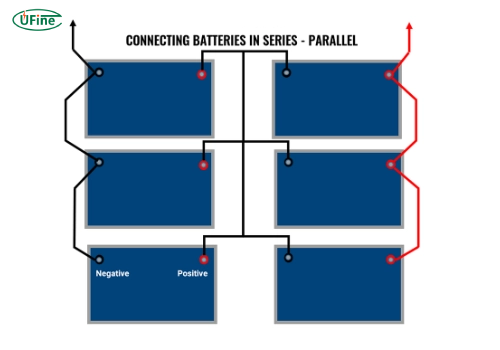

Lithium-ion battery Series-parallel Combination

Optimized performance:

Series-parallel combinations leverage both increased voltage and enhanced capacity. This configuration connects sets of cells in series and then connects these sets in parallel, offering a balance between voltage and capacity improvements.

Customizable configurations:

Manufacturers can customize battery packs by arranging cells in series-parallel combinations to meet specific voltage and capacity requirements of different applications, ranging from consumer electronics to energy storage systems.

Lithium-ion battery Application-specific Configurations

Electric vehicles (EVs):

EVs often use complex combinations of lithium-ion cells, balancing the need for high voltage to power the motor and increased capacity for longer driving ranges.

Portable electronics:

Smartphones, laptops, and other portable devices may use series or parallel configurations depending on the desired balance between voltage and capacity for optimal performance.

Part 5. Benefits of lithium-ion battery packs

High energy density

Lithium-ion battery packs offer high energy density, providing more energy storage capacity compared to other battery types of similar size and weight. This characteristic is crucial for portable electronics and electric vehicles where space is limited.

Extended battery life

The high energy density of lithium-ion packs allows for extended device usage between charges. This feature enhances user convenience and improves the overall experience with electronic devices.

Fast-charging capability

They also support fast-charging technology, allowing users to recharge devices quickly, and providing convenience in situations where immediate power is necessary.

Recyclability

These battery packs are also recyclable, allowing for the recovery of valuable materials like lithium, cobalt, and nickel. Proper recycling methods help reduce the environmental impact and ensure the responsible disposal of battery components.

Part 6. FAQs

-

What are lithium-ion battery packs used for?

Lithium-ion battery packs are widely used in various applications such as consumer electronics (like smartphones and laptops), electric vehicles (EVs), renewable energy storage systems, power tools, and more due to their high energy density and rechargeable nature. -

How long do li-ion batteries last?

The lifespan of a Li-ion battery pack varies based on factors like usage, charging habits, and environmental conditions. Typically, they last around 2,000 to 3,000 charge cycles or roughly 5 to 10 years before experiencing significant capacity loss. -

How do you charge a lithium-ion battery pack?

Charging a lithium-ion battery pack involves using a compatible charger designed for Li-ion batteries. Ensure the charger matches the battery pack’s voltage and current specifications and follow manufacturer recommendations for safe and efficient charging. -

What happens to used lithium-ion battery packs for electric cars?

After their use in electric cars, lithium-ion battery packs often undergo recycling processes. These processes involve extracting valuable materials like lithium, cobalt, and nickel to be reused in new batteries or other industries, minimizing environmental impact and optimizing resource utilization.

Related Tags:

More Articles

LiPo Battery Discharge Rate Guide & Calculation Tips

Understand LiPo battery discharge rates, C-ratings, and how to calculate max current. Essential guide for RC, drones, and electronics users.

High‑Capacity 3S LiPo Batteries: 5000 mAh vs. 10000 mAh

Compare 3S LiPo 5000mAh vs 10000mAh batteries by weight, power, and use. Find the best fit for your drone, RC car, or boat setup.

Top 5 Applications for Small 3S LiPo Batteries

Small 3S LiPo batteries power drones, RC gear, wearables, and robotics with high energy and low weight. Making them ideal for compact electronics projects.

Building and Charging Your Own 3S LiPo Pack: A Step‑by‑Step Guide

Learn how to build, balance, and charge a 3S LiPo battery pack safely at home with this complete DIY guide for hobbyists and beginners.

How to Choose the Right LiPo Battery Plug Type?

Discover the best LiPo battery plug types, how to choose them, and expert tips for safe usage, soldering, and maintenance.