Lithium-ion battery pack mainly has two meanings. The first is the processing and assembly of lithium-ion battery packs. The second type is similar to customized processing and assembly. Nowadays, the meaning of essential battery packs is the second one.

A lithium-ion battery pack mainly combines battery cells, battery PCB, battery connecting sheets, label paper, etc., through the battery pack assembly process to process them into the products that customers want.

Lithium-ion battery packs are now mainly concentrated in lithium-ion battery pack factories. Lithium-ion battery pack suppliers like Ufine have their pack structure design, pack electronic design, and pack production workshop and can carry out independent development and design according to customer needs.

The basic process of custom lithium battery packs is that after the battery specifications and samples meet the customer’s customized lithium-ion battery needs and are confirmed, the pack production line in the packing workshop will be produced and processed. After passing the quality inspection, it will be shipped and delivered to the customer.

Part 1. What is the lithium-ion battery pack?

First, we need to understand the generaldifferences between lithium battery cells, batterry module, and battery packs.

How to Distinguish Battery Cells, Battery Modules, And Battery Packs?

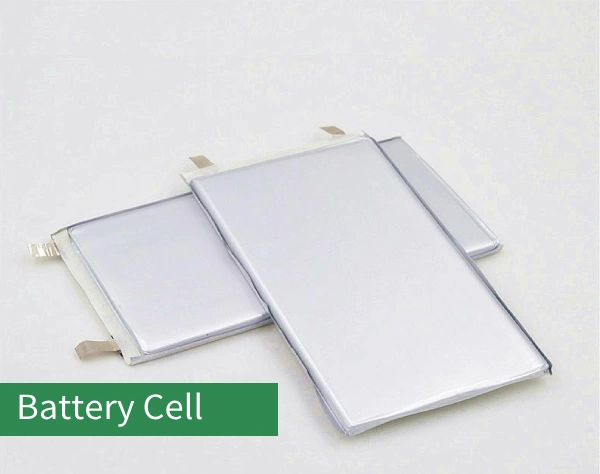

- Battery cell: Battery cell is the most essential element that makes up the battery pack and pack. Generally, the voltage it can provide is between 3v-4v;

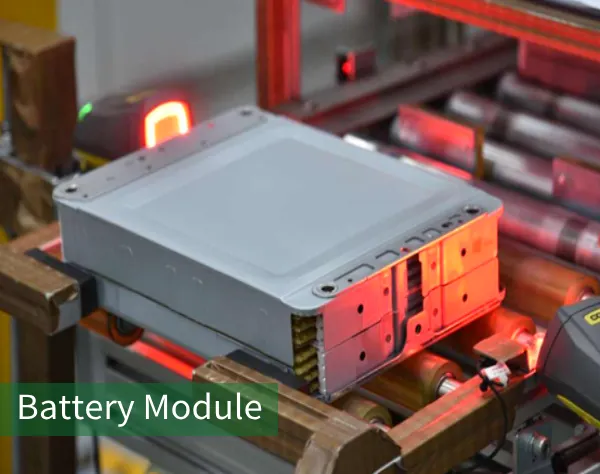

- Battery module: A collection of multiple cells to form a single physical module. This provides higher voltage and capacity;

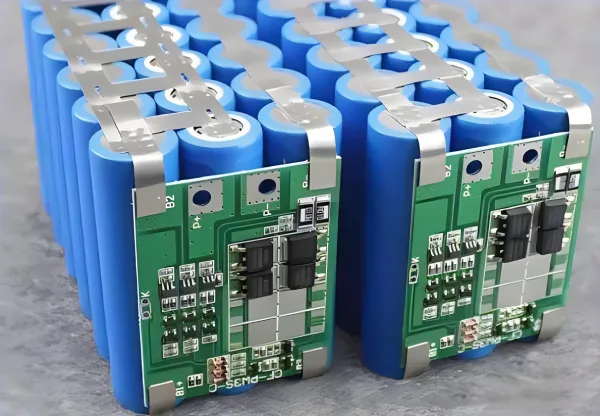

- Battery pack: Generally composed of multiple battery modules. A battery management system (BMS) has also been added. That is the final product provided by the power manufacturer to the user.

As the core component of lithium-ion battery packs, battery cells are currently classified into three main categories based on their appearance: square case batteries, cylindrical batteries, and lithium polymer battery. The positive and negative electrodes of the battery are packaged into corresponding casings in different ways.

Part 2. What’s inside the lithium-ion battery pack?

Lithium-ion battery packs mainly include a battery module, mechanical system, electrical system, thermal management system, and BMS.

1. Battery module

If the lithium-ion battery pack is compared to a human body, the battery module is the “heart.” It is responsible for storing and releasing energy to power electronic devices.

2. Institutional system

It is mainly composed of a battery pack upper cover, tray, various metal brackets, end plates, and bolts. It can be regarded as the “skeleton” of the battery pack, which plays the role of support, resistance to mechanical impact, mechanical vibration, and environmental protection (waterproof and dustproof).

3. Electrical system

It mainly comprises high-voltage jumpers or high-voltage wire harnesses, low-voltage wire harnesses, and relays. The high-voltage wiring harness can be regarded as the “main artery” of the lithium-ion battery pack, continuously delivering the power of the heart of the power battery system to various required components. The low-voltage wiring harness can be regarded as the “neural network” of the battery pack, transmitting detection and control signals in real-time.

4. Thermal management system

There are four main categories of thermal management systems: air cooling, water cooling, liquid cooling, and phase change materials. Take the water cooling system as an example. The thermal management system mainly consists of cooling plates, water pipes, thermal insulation, and thermal conductive pads. The thermal management system is equivalent to installing an air conditioner on the lithium-ion battery pack.

5. BMS

Battery management systems can be regarded as the “brain” of the battery, mainly composed of CMU and BMU.

CMU: Cell Monitor Unit responsible for measuring battery voltage, current, temperature, and other parameters. It also has equalization and other functions. When the CMU measures these data, it transmits them to the BMU through the battery “neural network” mentioned earlier.

BMU: Battery management unit. Responsible for evaluating the data transmitted by the CMU. If the data is abnormal, the battery is protected, a request is issued to reduce the current or the charge and discharge path is cut off to prevent the battery from exceeding the permitted usage conditions. At the same time, the battery power and temperature are also managed. According to the previously designed control strategy, the parameters and status that require warning are determined, and the warning is sent to the equipment controller and finally communicated to the equipment user.

Part 3. Battery pack assembly process: how to build a lithium-ion battery pack?

1. Battery cell selection and matching group

Sorting and matching groups is the first step in lithium-ion battery pack manufacturing. This link is like selecting an athlete, selecting battery cells with similar performance to lay the foundation for subsequent assembly work. Through rigorous testing, including battery cell capacity, internal resistance, open circuit voltage, and many other indicators, the cells are carefully classified and grouped to ensure that the performance of each group of cells is as consistent as possible.

2. Battery cell assembly and welding

In addition, the battery core assembly and welding links closely combine the battery core with the protection circuit module (PCM) or battery management system (BMS). In this process, the cooperation of automated equipment and skilled workers is crucial. They use advanced fixtures and welding equipment to fix the cells precisely in designated positions and connect the various components firmly through precise welding techniques. In this way, a battery pack that has begun to take shape appears before our eyes.

3. Battery insulation and testing

However, the lithium-ion battery pack manufacturing process continues. The insulation and testing of semi-finished lithium battery packs follow closely to ensure the safety of the battery pack.

Workers carefully wrapped the voltage collection lines and wires with insulating materials to ensure the lithium battery pack would not cause short circuits or other safety accidents during operation.

At the same time, the strict testing process is a comprehensive inspection of the battery pack performance, including charge and discharge testing, internal resistance testing, capacity testing, and many other contents. Only battery packs that pass these tests can advance to the next step.

4. Packaging

In the packaging process of the lithium-ion battery pack, the battery pack is given a more beautiful and practical appearance. According to the design requirements, the battery pack is wrapped in exquisite packaging materials, which not only enhances the product’s overall image but also increases its durability and portability. At the same time, reasonable packaging design can also ensure the safety of the battery pack during transportation and use.

The entire lithium battery pack testing, packing, and shipping process brings a successful conclusion to the manufacturing of lithium-ion battery packs. At this stage, the battery pack undergoes a final comprehensive inspection to ensure its performance meets customer requirements and safety standards. They are then neatly packed into cartons or wooden racks, ready to embark on their journey to the customer.

Part 4. Summary

In short, battery pack manufacturing is a process entirely of technology and wisdom. From sorting and assembling to packing and shipping, every step embodies the hard work and sweat of the workers. These fine craftsmanship and strict quality control create lithium-ion battery packs with excellent performance, safety, and reliability, providing steady power for our lives.

Related Tags:

More Articles

Gravity Battery vs. Traditional Battery: A Comparative Analysis

Gravity batteries use gravitational energy for storage. This article compares them to traditional batteries, exploring mechanisms, advantages, and applications.

What Is a Gravity Battery?

A gravity battery stores electricity using gravitational energy. This article explores its mechanics, benefits, and real-world applications in renewable energy.

How to Choose the Right Battery Relay for Your Vehicle?

Choosing the right battery relay ensures optimal performance. This article explores key factors and answers common questions for selecting a reliable relay.

What to Know Before Buying a Riding Mower Battery

Ready to buy a riding mower battery? Learn the key factors to consider. Discover what you need to choose the best battery today!

Understanding Battery Relay: A Comprehensive Guide

Battery relays are essential for managing power efficiently. This guide covers their functions, types, and applications for DIY enthusiasts and vehicle owners.