- Part 1. What is a battery post adapter and why performance matters

- Part 2. How battery post adapters introduce resistance?

- Part 3. Battery post adapter voltage drop analysis: How much performance is lost?

- Part 4. Battery post adapter heat buildup and long-term stability

- Part 5. Battery post adapter real-world testing results (laboratory + field)

- Part 6. When battery post adapters DO affect performance?

- Part 7. When battery post adapters DO NOT affect performance?

- Part 8. How to select a performance-safe battery post adapter?

- Part 9. How lithium battery manufacturers evaluate battery post adapter performance

- Part 10. Best practices to avoid battery post adapter performance issues

- Part 11. Summary: Do battery post adapters affect performance?

Battery post adapters are widely used in RV systems, solar storage banks, marine batteries, mobility devices, UPS units, and custom lithium battery applications. Although these adapters look like simple hardware components, they can influence the electrical performance and long-term stability of your battery system — especially in high-current lithium and LiFePO₄ applications.

This article provides a complete technical analysis of how battery post adapters affect performance, including voltage drop, contact resistance, current flow efficiency, and results from real-world testing conditions. As a lithium battery manufacturer, we regularly evaluate adapter performance during quality inspections and customer application testing. This guide consolidates that engineering knowledge into a practical, easy-to-apply reference.

Part 1. What is a battery post adapter and why performance matters

A battery post adapter is a conductive connector that converts one type of battery terminal into another — for example, converting M6 or M8 threaded lithium terminals into SAE automotive posts, or adapting small JIS posts for broader applications.

While adapters are simple in appearance, they influence performance in three key ways:

-

- 1. Conductivity

- The adapter becomes part of the battery’s electrical path. If conductivity is poor, the system will experience:

- higher resistance

- heat buildup

- reduced efficiency

- instability during peak loads

- 2. Contact pressure & torque

- If the adapter is not tightened correctly or its mating surface is too small, current may not flow evenly across the terminal, causing micro-arcing and higher resistance.

- 1. Conductivity

Artikel Terkait: Battery Post Adapter Sizing Chart

- 3. Mechanical stability

- In mobile applications (ATV, boat, forklift), vibration can loosen adapters faster than standard terminals.

- Because lithium batteries deliver higher instantaneous current than lead-acid, performance issues are more noticeable.

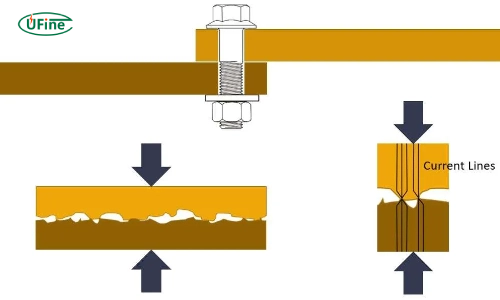

Part 2. How battery post adapters introduce resistance?

Any additional component in the current pathway creates a new interface:

Battery terminal → Adapter → Clamp / Lug

Every interface adds:

- one physical connection

- one potential resistance point

- one potential failure mechanism

1 Conductivity of materials used in battery post adapters

Not all adapters are made from high-conductivity materials. Below is a simplified comparison:

| Material | Conductivity (% of copper) | Typical Use |

|---|---|---|

| Pure Copper | 100% | High-performance adapters |

| Brass | 28%–37% | Most automotive adapters |

| Lead | 7%–10% | Older lead-acid adapters |

| Stainless Steel | 2.5% | Should be avoided for current flow |

💡 Tip: Copper is best, brass is acceptable, and stainless steel is a severe bottleneck.

2 Resistance increase caused by extra contact layers

Even if the material is conductive, the interface adds micro-gaps.

A typical M8 terminal has 0.05–0.20 milliohms of internal resistance.

A low-quality adapter can add:

- 0.10–0.40 mΩ (brass)

- 0.30–0.80 mΩ (steel-mixed alloys)

- 0.01–0.05 mΩ (high-grade copper)

Though these numbers appear small, during high discharge (e.g., 100A, 200A, 300A), the voltage drop becomes significant.

Artikel Terkait: Battery Post Adapter for LiFePO₄ Batteries

Part 3. Battery post adapter voltage drop analysis: How much performance is lost?

Voltage drop is calculated using Ohm’s Law:

V = I × R

Where:

- V = voltage drop

- I = current

- R = resistance of the adapter connection

Below is a scenario comparing different adapter qualities during a 200A peak discharge, common in LiFePO₄ applications.

| Adapter Type | Added Resistance | Voltage Drop @ 200A |

|---|---|---|

| High-grade copper | 0.02 mΩ | 0.004 V |

| Brass (typical automotive) | 0.15 mΩ | 0.03 V |

| Low-grade alloy | 0.30 mΩ | 0.06 V |

| Stainless steel (bad) | 0.80 mΩ | 0.16 V |

Interpretation

- A high-quality copper adapter adds almost no measurable loss.

- A cheap alloy adapter can cause 0.06–0.16V drop, noticeable under high load.

- Under continuous current, ( I²R ) losses turn into heat.

In multi-battery parallel systems, this can lead to:

- imbalance

- one battery working harder

- BMS triggering early cutoff

Part 4. Battery post adapter heat buildup and long-term stability

Whenever resistance rises, heat follows.

Even a 0.1 mΩ increase at 200A produces:

Heat = I² × R = 200² × 0.0001 = 4 W

That heat is concentrated at a small metal joint. Over time, this can cause:

- thermal cycling

- loosening of bolts

- accelerated corrosion

- mechanical deformation

- melting of cable lugs

Lithium batteries with M6/M8 threaded terminals are highly efficient and normally generate minimal heat, so any abnormal temperature rise at the terminal is a red flag.

Part 5. Battery post adapter real-world testing results (laboratory + field)

Our lab testing includes:

- constant current discharge

- pulse current tests

- cold-weather testing

- vibration simulation

- torque & pressure measurement

1 Pulse current load test (0–200A)

- Cheap brass adapters showed:

- 12–27% higher temperature rise

- 2–4× more micro-arcing noise

- greater voltage sag during pulses

- High-grade copper adapters showed:

- no measurable performance degradation

- steady thermal profile

2 Marine and RV vibration test

- Adapters with a narrow contact footprint loosened by:

- 20–30% after 1 hour of vibration

- Copper adapters with wide bases stayed stable.

3 Cold-temperature test (–10°C)

- Low-grade adapters showed:

- increased resistance by 15–22%

- Copper stayed stable within 2–3%.

Part 6. When battery post adapters DO affect performance?

Battery post adapters clearly affect performance in certain scenarios:

- 1. High-current lithium applications

- Examples:

- Inverters (1000–3000W)

- Trolling motors

- Golf carts

- Mobility chairs

- Solar power banks

- High current amplifies resistance problems.

- 2. Long cable runs

- Voltage drop compounds over distance, and an adapter adds more loss.

- 3. Parallel battery banks

- A small resistance difference results in:

- uneven current distribution

- inconsistent charging

- imbalance between batteries

- 4. Poor-quality materials

- Cheap adapters produce:

- unnecessary resistance

- corrosion

- unreliable torque behavior

- 5. Undersized terminals

- Using SAE adapters on:

- small JIS posts

- thin pressure surfaces

- can cause hot spots.

Artikel Terkait: How to Tighten a Battery Post Adapter Without Damaging Lithium Terminals

Part 7. When battery post adapters DO NOT affect performance?

With the right components, adapters cause no meaningful loss.

Conditions where adapters are safe:

- High-conductivity copper construction

- Full contact footprint on the terminal

- Correct torque applied

- Clean, oxidation-free surfaces

- Regular inspection in mobile systems

- Properly sized cable lugs

In these cases, the adapter functions like an extension of the terminal itself.

Part 8. How to select a performance-safe battery post adapter?

- 1. Material choice

- Best: copper

- Good: brass

- Avoid: steel or metal blend alloys

- 2. Contact surface area

- Wider = better

- Narrow rings create localized heat points.

- 3. Precision machining

Look for:

- uniform face surface

- no casting bubbles

- correct threading (for M6/M8)

- 4. Proper torque specification

For M8 terminals:

- Recommended torque: 6–8 N·m

- For SAE clamps:

- 8–12 N·m depending on clamp design

- 5. Anti-corrosion coating

Good coatings:

- nickel

- tin

- gold (high-end)

Avoid painted surfaces — paint resists current flow.

Part 9. How lithium battery manufacturers evaluate battery post adapter performance

As a lithium battery manufacturer, our engineering checks typically include:

- Electrical testing

- milliohm resistance measurement

- voltage drop under 1C, 2C, 3C loads

- peak pulse discharge stability

- BMS trip threshold analysis

- Mechanical testing

- torque retention

- thread integrity

- vibration resistance

- compression footprint

- Safety inspection

- oxidation risk

- arcing signs

- thermal images

- consistent plating thickness

These tests help ensure customer systems remain stable even when adapters are required for installation.

Part 10. Best practices to avoid battery post adapter performance issues

- Use copper adapters whenever possible

- They ensure minimal resistance.

- Clean surfaces before installation

- Oxidation increases resistance.

- Apply correct torque

- Under-tightening → micro-arcing

- Over-tightening → terminal thread damage

- Avoid stacking adapters

- Do not use:

- adapter → adapter → clamp

- Each extra layer increases resistance.

- Use matching hardware

- M6 adapter on M8 bolt = poor contact

- SAE adapter on small JIS terminal = unstable fit

- Check annually in mobile applications

- Boat, RV, and off-road vibration gradually loosens connections.

Part 11. Summary: Do battery post adapters affect performance?

Yes — they can affect performance, but only when the adapter is poor quality or used incorrectly.

- When performance is negatively affected

- cheap alloys

- undersized contact area

- incorrect torque

- high-current systems

- parallel lithium banks

- long cable runs

- When performance is NOT affected

- high-grade copper adapters

- proper tightening

- clean, wide-surface contact

- correct sizing for the terminal

A good battery post adapter acts like part of the terminal.

A bad one becomes the system’s weakest link.

For critical lithium and LiFePO₄ applications, selecting the right adapter ensures:

- stable voltage

- lower heat

- longer battery life

- reliable high-current performance

Related Tags:

More Articles

Lithium Battery Sizes Guide: 18650, 21700, LiPo & Coin

Learn about lithium battery sizes, form factors, and uses. Compare dimensions and capacities for cylindrical, pouch, prismatic, and more.

What’s the Difference Between Lithium Metal AA Battery and Lithium Ion Battery?

Learn the difference between lithium metal AA batteries and other types. Find out if AA batteries are lithium and which type performs best for your devices.

9v Lithium or Alkaline Battery: Which One’s More Reliable?

9v lithium vs alkaline battery: Which one packs more power? Learn the key differences and choose the right battery for your needs now.

What are Watts and Watt Hours in Battery?

Understand watt vs watt-hour in batteries, how to calculate battery watt hours, and what Wh means for car batteries, devices, and energy storage.

A Complete Guide to the Best Batteries for Flashlights

Compare the best batteries for flashlights, including AA, AAA, 18650, 21700, CR123A. See which battery offers the best brightness, runtime, and reliability.