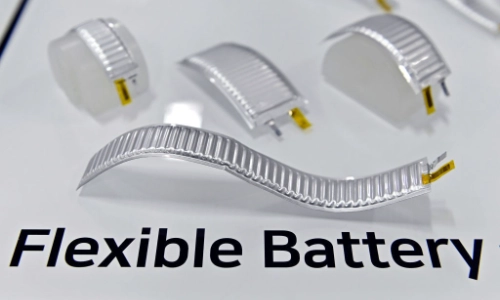

In recent years, there have been significant advancements in battery technology, leading to the development of flexible batteries. These innovative power sources offer a range of benefits and have the potential to revolutionize various industries. This article will explore the world of flexible batteries, discussing their importance, components and materials, advantages and disadvantages, applications, and manufacturing techniques.

Part 1. What are flexible batteries?

Flexible batteries are a type of energy storage device that can bend, twist, and conform to different shapes and surfaces without losing their functionality. Unlike traditional rigid batteries, which typically have a bulky and inflexible design, manufacturers design them ultra-thin and lightweight, making them ideal for applications where flexibility is crucial.

Importance of Flexible Battery Technology

Flexible battery technology holds immense importance in today’s world due to its ability to overcome the limitations of traditional batteries. The flexibility enables integration into various devices and systems, opening up innovative possibilities for industries such as healthcare, wearables, the Internet of Things (IoT), and more. These batteries provide a power source that can adapt to the shape and form of the devices they are used in, enhancing both design and functionality.

The increasing popularity of wearable devices like smartwatches, fitness trackers, and electronic textiles has fueled the demand for flexible batteries. These devices require lightweight and flexible power sources that can comfortably fit into small form factors without compromising performance.

Part 2. Flexible battery components and materials

Flexible batteries have several key components and materials that enable their unique properties and functionality. Here are the main components found in most flexible batteries:

Electrodes

Flexible batteries typically employ two types of electrodes: a cathode and an anode. These electrodes are responsible for the movement of ions and electrons during the charging and discharging processes. Materials commonly used for the electrodes include lithium cobalt oxide for the cathode and graphite or lithium titanate for the anode.

Electrolyte

The electrolyte in a flexible battery serves as a medium for ion transport between the cathode and anode. It allows the movement of ions while preventing the flow of electrons, ensuring the battery functions correctly. Flexible batteries often utilize polymer electrolytes, gel electrolytes, or solid-state electrolytes because they can maintain flexibility.

Substrates

Flexible batteries are typically constructed on flexible substrates to achieve flexibility. These substrates are thin and bendable materials that provide mechanical support to the battery components. Typical substrate materials include polymers like polyethylene terephthalate (PET) or polyimide (PI).

Part 3. Flexible battery advantages and disadvantages

Flexible batteries offer a range of advantages that make them highly desirable for various applications. However, they also come with a few limitations. Let’s explore both the advantages and disadvantages of flexible batteries:

Advantages

- Flexibility: The primary advantage of flexible batteries is their ability to bend and conform to different shapes, allowing seamless integration into various devices and systems.

- Lightweight: Flexible batteries are significantly lighter than their rigid counterparts, making them ideal for applications where weight is a concern, such as wearable devices.

- Enhanced design possibilities: The flexibility of these batteries enables innovative design possibilities, leading to the development of sleeker, more compact devices with improved aesthetics.

- Improved safety: Flexible batteries often utilize solid-state electrolytes, which offer better protection than traditional liquid electrolytes in rigid batteries.

Disadvantages

- Lower energy density: Flexible batteries generally have a lower energy density than traditional batteries. This means they may provide less power or runtime, which can be a limitation in some applications.

- Limited cycle life: The repeated bending and flexing of flexible batteries may affect their lifespan, leading to a shorter cycle life than rigid batteries.

- Complex manufacturing processes: Manufacturing flexible batteries can be more challenging and complex than traditional batteries, which may result in higher production costs.

Part 4. What are flexible batteries used for?

Flexible batteries have applications in various industries, driving innovation and enabling new possibilities. Here are some common uses of flexible batteries:

Wearable devices

Wearable devices such as smartwatches, fitness trackers, and electronic textiles extensively use flexible batteries. The flexibility of these batteries allows for comfortable integration into wearable products, ensuring a seamless user experience.

Medical devices

In the healthcare industry, flexible batteries have enabled advancements in medical devices. They can be integrated into wearable health monitors, implantable devices, and drug delivery systems, providing a reliable and flexible power source for these devices.

Internet of Things (IoT)

Interconnected devices in the Internet of Things require integrating power sources into various form factors. Flexible batteries are vital in powering these IoT devices, enabling seamless connectivity and functionality in multiple applications, including smart homes, industrial automation, and environmental monitoring systems.

Consumer electronics

The consumer electronics industry has also benefited from the advancements in flexible battery technology. Flexible batteries can be integrated into smartphones, tablets, e-readers, and other portable devices, providing a lightweight and flexible power source that enhances user experience and design possibilities.

Part 5. Flexible battery manufacturing techniques

Manufacturing flexible batteries involves specialized techniques to ensure their flexibility and performance. Here are some commonly used manufacturing techniques:

Roll-to-Roll Manufacturing

Roll-to-roll (R2R) manufacturing processes battery components continuously on a flexible substrate in a roll form. This method allows for high-speed and cost-effective production of flexible batteries, making it suitable for large-scale manufacturing.

Printing Technologies

Printing technologies, such as screen printing and inkjet printing, have been adapted for flexible battery manufacturing. These techniques enable the precise deposition of battery materials onto flexible substrates, offering flexibility in design and customization.

Thin-Film Deposition

Thin-film deposition techniques, such as physical vapor deposition (PVD) and chemical vapor deposition (CVD), are employed to create thin layers of battery materials on flexible substrates. These techniques ensure uniformity and precise control over the thickness of the battery layers.

Part 6. Conclusion

In conclusion, flexible batteries are a game-changer in battery technology. With their ability to bend, twist, and adapt to various shapes, they offer a new level of convenience and innovation. From wearable devices to medical applications and the Internet of Things, flexible batteries are powering the future. Although they have some limitations, ongoing research and development are paving the way for even better performance and efficiency. Get ready for a flexible and connected future powered by these remarkable batteries!

Related Tags:

More Articles

Comprehensive Guide to Choosing the Right Cart Battery

Choosing the right cart battery ensures optimal performance and longevity. This guide covers cart battery types and helps you make an informed choice.

The Ultimate Guide to 18650 Button Top Battery

18650 button top batteries are popular for their high energy density and reliability. This guide covers their key features, usage, and maintenance tips.

The Power of Slim: Unveiling the Potential of Flat Lithium Ion Battery

Flat lithium-ion batteries power devices from phones to vehicles. This article explores their design, benefits, types, applications, charging, and safety.

The Comprehensive Guide to Battery Balancing and Battery Balancer

Battery balancing and balancers optimize performance, longevity, and safety. This guide covers techniques and tips for choosing the right balancer.

10 Key Facts About Drone Battery for 2024

Uncover crucial insights with "10 Key Facts About Drone Battery for 2024." Learn the latest trends and essential details on drone batteries.