Battery assembly is the process of assembling parts to create a functioning battery. This involves combining essential components like cells and connectors. Using the right tools and following precise steps is necessary to ensure the battery works properly. This article explores techniques, tools, and best practices for assembling batteries, focusing on efficiency and safety.

Part 1. Essential components of a lithium battery

Battery Anode and Cathode Materials

- Anode: Lithium batteries typically use graphite for the anode, which has a structure enabling it to intercalate lithium ions during charging. This process is essential for storing energy efficiently.

- Cathode: Lithium batteries use various materials for the cathode, such as lithium cobalt oxide (LCO), lithium manganese oxide (LMO), lithium nickel manganese cobalt oxide (NMC), and lithium iron phosphate (LFP). Each cathode material offers different performance characteristics, including energy density and stability.

Battery Electrolytes and Separators

- Electrolytes: Electrolytes are crucial for conducting lithium ions between the anode and cathode during charge and discharge cycles. Common electrolytes include lithium salts such as lithium hexafluorophosphate (LiPF6) dissolved in organic solvents like ethylene carbonate. They enable the movement of ions necessary for battery operation.

- Separators: Separators are thin membranes placed between the anode and cathode to prevent electrical short circuits while allowing the passage of lithium ions. Manufacturers typically make them from polyethylene or polypropylene, which allows ions to pass through but insulates electrically.

Battery Housing and Insulation Materials

- Housing: The housing of lithium batteries provides physical protection and structural integrity. Manufacturers typically make it from aluminum, steel, or plastic, depending on the battery type (cylindrical, prismatic, or pouch). The housing also includes features for electrical contacts and terminals.

- Insulation Materials: Inside the battery housing, insulation materials prevent components from coming into contact and causing short circuits. Common insulation materials include polyester films and ceramic coatings, which ensure the safety and reliability of the battery during operation.

Part 2. Types of lithium batteries

Lithium-ion Batteries

- Composition: Lithium-ion batteries (Li-ion) use lithium compounds as electrolytes, allowing ions to move between the anode and cathode during charging and discharging.

- Structure: Typically cylindrical or prismatic, manufacturers widely use them in consumer electronics, electric vehicles, and energy storage systems.

- Advantages: High energy density, longer cycle life, and lower self-discharge rates than other battery types.

Lithium Polymer Batteries

- Composition: Lithium polymer batteries (LiPo) use a solid polymer electrolyte instead of liquid, enabling flexibility in design and shape.

- Structure: Commonly found in slim, lightweight pouch formats, manufacturers favor them for applications where the form factor is critical, such as smartphones and wearable devices.

- Advantages: Higher energy density per unit volume, lighter weight, and greater design flexibility than traditional Li-ion batteries.

Differences in Battery Assembly Techniques

Lithium-Ion Battery Assembly:

- Involves stacking layers of anodes, cathodes, and separators.

- Assembly techniques include winding for cylindrical cells and stacking for prismatic cells.

- Requires careful handling of liquid electrolytes during assembly.

Lithium Polymer Battery Assembly:

- Utilizes a lamination process to encapsulate layers of electrodes and electrolytes in flexible pouch formats.

- Requires precise control of temperature and pressure to ensure uniformity and prevent defects.

- Assembly techniques focus on sealing pouches securely to maintain integrity and prevent leakage.

Part 3. Tools and equipment for lithium battery assembly

Battery Cell Handling Tools

- Purpose: These tools facilitate safely handling and manipulating battery cells during assembly.

- Examples: Tweezers, vacuum pens, and cell holders ensure precise positioning and prevent contamination.

- Importance: Proper handling tools minimize the risk of damage to sensitive battery components and ensure assembly accuracy.

Spot Welders and Tab Welding Equipment

- Functionality: Spot welders and tab welding machines are essential for securely connecting electrodes and tabs.

- Process: They use high current pulses to weld metal tabs onto battery terminals, ensuring low resistance connections.

- Applications: Commonly used in both manual and automated assembly lines for cylindrical and prismatic battery formats.

Vacuum Chambers and Glove Boxes for Controlled Environments

- Purpose: Vacuum chambers and glove boxes create controlled environments free from moisture and oxygen.

- Usage: Used during electrolyte filling and sealing processes to maintain battery integrity.

- Benefits: Prevents contamination, enhances safety, and improves the reliability of assembled lithium batteries.

Part 4. Steps in the lithium battery assembly process

Cell Preparation and Inspection

- Preparation: Begin by inspecting and preparing battery cells for assembly.

- Cleaning: Workers clean cells to remove contaminants that could affect performance.

- Testing: Perform initial voltage and capacity checks to ensure cell quality meets specifications.

- Inspection: Before proceeding, visual inspection for physical defects such as dents or leaks.

Electrode Coating and Assembly

- Coating Process: Apply electrode materials (anode and cathode) onto current collectors.

- Slurry Application: Coat current collectors with electrode materials using precision coating techniques.

- Drying: Dry electrodes in controlled environments to remove solvents and solidify the electrode layers.

- Assembly: Stack-coated electrodes with separators to form cell layers ready for final assembly.

Cell Stacking and Encapsulation

- Stacking: Layer electrodes and separators in precise sequences to optimize battery performance.

- Alignment: Ensure electrodes are aligned correctly to maximize contact and conductivity.

- Compression: Apply controlled pressure to compact cell layers for improved energy density.

- Encapsulation: Seal stacked cells within protective casings (e.g., aluminum cans or flexible pouches).

- Sealing: Use heat sealing or welding techniques to secure battery housing and prevent leaks.

- Final Inspection: Conduct a final inspection to verify integrity and functionality before shipment.

Part 5. Quality control measures in battery assembly

Testing and Validation Processes

- Initial Testing: Conduct voltage and capacity checks on individual battery cells before assembly.

- In-Process Testing: Monitor critical parameters during electrode coating, stacking, and encapsulation stages.

- Criteria: Ensure adherence to specified dimensions, weight, and electrical characteristics tolerances.

- Final Testing: Perform comprehensive tests on fully assembled batteries to verify performance and reliability.

- Tests Include: Capacity measurement, cycle life testing, and safety assessments.

Failure Analysis and Corrective Actions

- Root Cause Analysis: Investigate any deviations or failures encountered during testing.

- Identify Issues: Pinpoint reasons for capacity loss, leakage, or electrical failures.

- Corrective Actions: Improve materials, processes, or equipment to prevent recurrence.

- Continuous Improvement: Iteratively refine assembly procedures based on analysis findings.

Part 6. Safety considerations during lithium battery assembly

Handling of Flammable Electrolytes and Materials

- Safety Protocols: Strict adherence to protocols for handling and storing electrolytes.

- Safety Equipment: Use protective equipment (PPE) such as gloves and goggles.

- Spill Management: Procedures in place to contain and neutralize electrolyte spills promptly.

- Fire Safety: Fire suppression systems and extinguishers are accessible in assembly areas.

Protection Against Short Circuits and Thermal Runaway

- Separator Quality: Ensure separators are defect-free and properly installed to prevent short circuits.

- Thermal Management: Implement measures for heat dissipation and temperature monitoring.

- Cell Design: Incorporate features like safety vents and thermal shutdown mechanisms to mitigate thermal runaway risks.

Part 7. Automation and innovation in lithium battery assembly

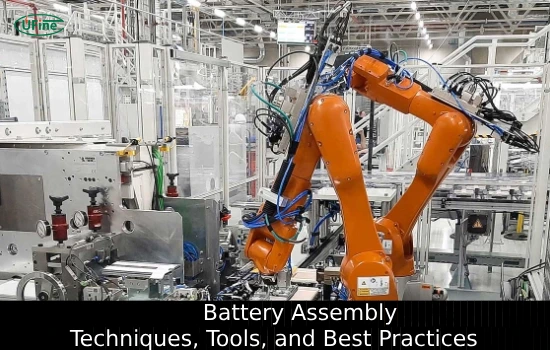

Advances in Automated Assembly Lines

- Automated Equipment: Using robotic arms and conveyor systems for efficient handling and assembly.

- Precision Assembly: Ensure consistent and accurate placement of components.

- Integration: Automated systems streamline processes from cell preparation to final packaging.

- Productivity Gains: Increase throughput and reduce labor-intensive tasks.

Robotics and AI Applications in Battery Manufacturing

- Robotics: Robots perform electrode coating, cell stacking, and quality inspection.

- AI Algorithms: AI algorithms analyze data to optimize assembly processes and detect anomalies.

- Innovation: Development of robotic cells capable of autonomous operation and adaptive learning.

- Future Trends: Continued integration of AI for predictive maintenance and quality enhancement.

Part 8. FAQs

-

How long do lithium batteries typically last?

Lithium batteries usually last between 2 to 5 years. This depends on usage, charging habits, and environmental conditions. Proper care, which includes avoiding deep discharges and high temperatures, can extend battery life. -

Can lithium batteries be recycled?

Yes. Recycling facilities can recycle lithium batteries. Specialized recycling facilities extract valuable materials like lithium, cobalt, and nickel from old batteries. It’s important to recycle batteries properly to reduce environmental impact. -

What is the difference between a lithium battery and a regular battery?

Lithium batteries have higher energy density and longer life than alkaline or nickel-cadmium (NiCd) batteries. They are also lighter and can hold a charge longer, making them ideal for high-drain devices like smartphones and electric vehicles. -

Are lithium batteries safe for air travel?

Lithium batteries are safe for air travel if they meet specific regulations. The Federal Aviation Administration (FAA) allows lithium batteries in carry-on baggage with restrictions on size and quantity. It’s essential to check particular airline guidelines before flying. -

What should I do if my lithium battery overheats?

If your lithium battery overheats, immediately disconnect it from any device or charger. Move it to a non-flammable surface and allow it to cool down.

Related Tags:

More Articles

Standard 24 Group Battery Dimensions Explained

What is 24 Group battery standard dimension? Find out now and choose the right battery for your needs. Don’t wait—get informed!

How Cobalt Free Batteries Are Transforming the Electric Vehicle Market?

Cobalt-free batteries are transforming the electric vehicle market with a sustainable choice. This article explores their benefits, challenges, and potential.

Lithium Manganese Batteries: A Comprehensive Guide

Lithium manganese batteries are transforming energy storage. This guide covers their mechanisms, advantages, applications, and limitations.

12 Volt 100Ah Lithium Battery: 12 Important Facts

Want to know about 12 Volt 100Ah lithium batteries? Explore essential facts that reveal their advantages and uses. Get informed today!

Why Choose a UPS Lithium Battery for Your Power Backup Needs?

Choosing the right battery for UPS systems is vital. UPS lithium batteries offer superior performance and longevity, making them perfect for power backup needs.