- Part 1. What is a 12 volt DC battery and how does it work?

- Part 2. Why OEMs must follow 12 volt DC battery safety standards?

- Part 3. Key international safety standards for 12V DC batteries

- Part 4. Common risks associated with 12 volt DC batteries

- Part 5. Best practices for battery installation and system design

- Part 6. Why every 12V lithium battery needs a Battery Management System (BMS)?

- Part 7. Environmental factors that affect 12 volt DC battery safety

- Part 8. Labeling, warnings, and emergency protocols for 12V batteries

- Part 9. Safe storage and transportation of 12 volt DC batteries

- Part 10. Testing and certification before market release

- Part 11. Designing OEM systems for user safety and reliability

- Part 12. Battery lifecycle management and safe disposal for OEMs

- Part 13. FAQs about 12 volt dc battery

12 volt DC battery safety standards are essential rules and guidelines that help manufacturers and engineers design safe, reliable products. These standards are especially important for OEMs (Original Equipment Manufacturers) that integrate batteries into vehicles, equipment, or consumer electronics.

A 12 volt DC battery may seem harmless because of its relatively low voltage. But if not handled properly, it can cause serious problems like overheating, fire, or even explosions. OEMs that overlook safety standards risk lawsuits, recalls, and damaged reputations.

In this detailed guide, we will cover the most important safety standards, explain why they matter, and provide practical tips for compliance. Whether you build RVs, solar equipment, or industrial tools, this guide will help you stay compliant, safe, and competitive.

Part 1. What is a 12 volt DC battery and how does it work?

A 12 volt DC battery is a type of direct current power source that delivers a constant 12 volts of electrical energy. It is one of the most commonly used batteries in the world and is found in:

- Cars and trucks

- Solar energy storage systems

- Recreational vehicles (RVs)

- Marine vessels

- Backup power systems

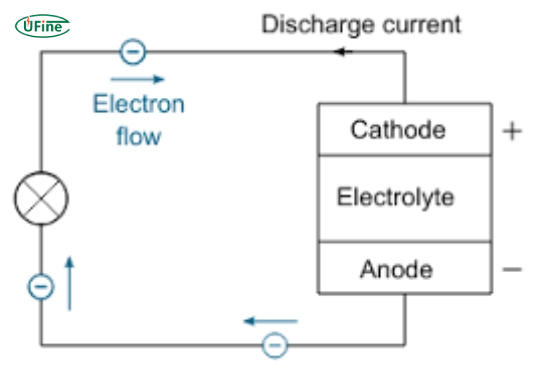

What is DC or direct current?

Direct current (DC) means the electricity flows in only one direction. This is different from alternating current (AC), which changes direction many times per second. Batteries always produce DC electricity, making them ideal for portable and low-voltage applications.

Part 2. Why OEMs must follow 12 volt DC battery safety standards?

OEMs are responsible for the safety and performance of every component they use in their products. When dealing with batteries, the risks are real. If you do not follow safety standards, you could end up dealing with:

- Injured users due to battery explosions

- Damaged products from overheating

- Regulatory fines and legal action

- Expensive recalls and warranty claims

Following approved safety standards helps OEMs to:

- Protect end users from harm

- Extend product life and reliability

- Reduce liability and insurance costs

- Build trust with global customers

Part 3. Key international safety standards for 12V DC batteries

There are several important global safety standards that apply to 12 volt DC batteries. OEMs must understand and follow these to ensure compliance and safety.

IEC 62133

This is a global standard for rechargeable batteries used in portable devices. It covers:

- Battery cell design and construction

- Overcharge protection

- Vibration and drop testing

- Short circuit and thermal safety

UL 2054

This standard is published by Underwriters Laboratories in the United States. It ensures that batteries for residential and commercial use are safe. Key requirements include:

- Fire resistance

- Electrical abuse protection

- Mechanical integrity

UN 38.3

This is required for transporting lithium batteries by air, sea, or land. It includes several tests:

- High altitude simulation

- Thermal testing

- Shock and vibration

- External short circuit

SAE J2464

This is a standard used in the automotive industry. It focuses on safety testing under abuse conditions such as:

- Crush

- Penetration

- Thermal exposure

By ensuring that your batteries meet these standards, you reduce the risk of failure and improve your product’s global acceptance.

Part 4. Common risks associated with 12 volt DC batteries

Even a 12 volt battery can be dangerous under the wrong conditions. OEMs must be aware of all possible risks, including:

Short circuits

A short circuit happens when the positive and negative terminals connect directly. This causes a large flow of current, which can lead to:

- Heat buildup

- Fire

- Battery rupture

Overcharging

Charging a battery beyond its capacity can cause internal pressure and heat. Over time, this leads to:

- Swelling

- Leakage

- Explosion

Reverse polarity

If the battery is connected backward, it can damage electronic components and cause sparks or fire.

Thermal runaway

This is a condition where the battery temperature increases uncontrollably. It is especially common in lithium-ion batteries and can result in fire or explosion.

Gas emission

Lead-acid batteries can release hydrogen gas during charging. In a closed space, this gas can ignite and cause an explosion.

Part 5. Best practices for battery installation and system design

OEMs should design battery systems that are safe, efficient, and error-proof. Here are key best practices:

Use proper insulation

All wiring and terminals should be insulated to prevent accidental shorts.

Secure the battery in place

Batteries should be mounted firmly to avoid movement or vibration. This prevents internal damage and loose connections.

Include ventilation

Especially for lead-acid batteries, proper airflow helps release gases safely and avoid pressure buildup.

Add fuses or circuit breakers

These protect the system from overcurrent or short circuits. Place them as close to the battery as possible.

Label everything clearly

Mark positive and negative terminals, voltage ratings, and safety warnings to avoid user mistakes.

Part 6. Why every 12V lithium battery needs a Battery Management System (BMS)?

A Battery Management System (BMS) is a critical safety tool that monitors the health and performance of a battery. It performs several functions:

- Prevents overcharging and over-discharging

- Balances cells to avoid voltage differences

- Detects overheating

- Sends alerts for failure conditions

For lithium batteries, having a BMS is not optional. It is the key to preventing thermal runaway and extending battery life. OEMs should always choose batteries with integrated or external BMS.

Part 7. Environmental factors that affect 12 volt DC battery safety

OEMs must design battery systems that can handle real-world environmental conditions. Here’s what to consider:

Temperature

Batteries have a safe operating range, usually between 0°C and 45°C. Extreme heat or cold can:

- Reduce capacity

- Cause swelling or leaks

- Trigger safety failures

Humidity and moisture

High humidity can cause corrosion, while water ingress can short internal circuits. Use sealed enclosures and IP-rated components.

Vibration and shock

In vehicles and mobile equipment, batteries are often exposed to vibration. Secure mounting and shock-absorbing materials can prevent damage.

Altitude

At high altitudes, air pressure drops. This can cause battery casing to deform, especially in sealed systems.

Part 8. Labeling, warnings, and emergency protocols for 12V batteries

OEMs must provide clear instructions and emergency systems to protect users. Here’s what to include:

Proper labeling

- Mark voltage, capacity, and chemistry type

- Indicate terminal polarity

- Use warning symbols for fire, explosion, and electric shock

Emergency shutdown systems

Design the system to safely power down in case of:

- Short circuit

- Overheating

- Internal failure

Include fire-resistant materials

Use fire-retardant plastics and insulation to contain any fire-related incidents.

Disposal instructions

Help users dispose of batteries safely by including recycling information and local regulations.

Part 9. Safe storage and transportation of 12 volt DC batteries

OEMs must follow strict protocols when storing or transporting batteries:

Storage

- Store in a cool, dry place

- Keep away from flammable materials

- Separate terminals to prevent short circuits

- Monitor for swelling or leakage

Transport

- Use certified packaging for lithium batteries

- Label packages with appropriate hazard symbols

- Provide documentation such as safety data sheets

- Train logistics partners in handling procedures

Part 10. Testing and certification before market release

Before launching a product with a 12 volt battery, OEMs must ensure it passes all relevant tests:

- Electrical safety tests for overcurrent, short circuit, and reverse polarity

- Thermal tests under various temperature conditions

- Mechanical tests for drop, vibration, and crush

- Chemical tests for leakage and gas release

Get certified by recognized bodies such as UL, IEC, or CE. Certification builds trust and opens global markets.

Part 11. Designing OEM systems for user safety and reliability

OEMs should create systems that are user-friendly and safe. Key design principles include:

- Easy-to-understand manuals

- Clearly marked battery compartments

- Built-in safety alerts for faults

- Modular systems for easy maintenance

By putting the user first, you reduce errors and increase satisfaction.

Part 12. Battery lifecycle management and safe disposal for OEMs

Batteries have a limited lifespan. OEMs must plan for:

- Safe removal and replacement

- End-of-life tracking systems

- Take-back or recycling programs

- Partnerships with certified disposal centers

Proper lifecycle management improves sustainability and meets environmental regulations.

Part 13. FAQs about 12 volt dc battery

Can a 12 volt DC battery explode?

Yes, if it is short-circuited, overcharged, or exposed to high temperatures. Safety features and proper design greatly reduce the risk.

What is a Battery Management System (BMS) and do I need it?

A BMS monitors battery performance and prevents failures. For lithium batteries, it is essential for safety.

Are lead-acid 12V batteries safe for indoor use?

Only sealed types like AGM or gel are safe for indoor use. Flooded batteries emit hydrogen gas and require ventilation.

How should OEMs store 12 volt batteries?

Store in a dry, cool place with terminals covered. Avoid stacking and check regularly for damage or leaks.

What tests are required before selling a battery-powered product?

Electrical, thermal, mechanical, and chemical safety tests are required. Certifications like UL, IEC, and CE ensure compliance.

Related Tags:

More Articles

Battery Load Test: A Comprehensive Guide

Step-by-step battery load test guide for car, solar & industrial use. Learn how to load test a battery, interpret voltage charts, and avoid common mistakes.

The Comprehensive Guide to Battery Balancing and Battery Balancer

Discover how battery balancers improve lithium battery performance, lifespan, and safety. Learn types, functions, and tips to choose the right balancer.

What Is the Best Voltage for a Chainsaw Battery?

Compare 12V-80V chainsaw batteries for light pruning, medium firewood, and professional cutting. See best battery chainsaw with runtime charts and safety tips.

Lithium VS. Alkaline Batteries: A Comprehensive Comparison

Lithium batteries last 3–7× longer than alkaline and perform better in cold weather. Compare lifespan, cost, safety, and best uses to choose the right battery.

Comparing Lithium-Sulfur and Lithium-Ion Batteries: Which is Right for You?

Compare lithium-sulfur (Li-S) and lithium-ion batteries on energy, lifespan, cost, safety, and applications. Best choice for drones, EVs, and electronics.