Lithium Iron Phosphate (LiFePO4) batteries are increasingly popular across various industries, from electric vehicles to renewable energy storage. Among the different formats of LiFePO4 cells, LiFePO4 prismatic cells, and cylindrical cells are two of the most widely utilized. Each has unique advantages and disadvantages, making them suitable for different applications. This comprehensive guide will delve deep into comparing LiFePO4 prismatic and cylindrical cells to help you determine which is better for your needs.

Part 1. What are LiFePO4 cells?

LiFePO4 (Lithium Iron Phosphate) cells are a type of lithium-ion battery that uses lithium iron phosphate as the cathode material. They offer several benefits, including high thermal stability, long cycle life, and excellent safety characteristics. These properties make them ideal for high-demand applications such as electric vehicles, power tools, and energy storage systems.

Part 2. Overview of cylindrical LiFePO4 cells

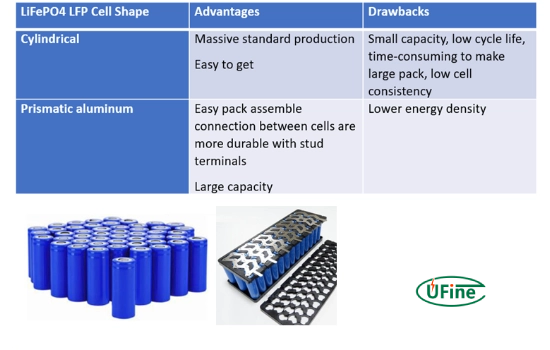

Cylindrical LiFePO4 cells are designed cylindrical, typically with a metal casing. The most common sizes include 18650 (18mm diameter and 65mm length) and 21700 (21mm diameter and 70mm length). The cylindrical design provides uniform mechanical stability and efficient heat dissipation.

Advantages of Cylindrical Cells

- High Energy Density: Cylindrical cells pack a significant amount of energy into a compact form, making them ideal for applications where space is limited.

- Better Thermal Management: The cylindrical shape allows for efficient cooling, reducing the risk of overheating.

- Manufacturing Efficiency: Their standardized design makes Cylindrical cells more accessible and cheaper.

- Mechanical Stability: The robust metal casing provides excellent protection against physical damage.

Disadvantages of Cylindrical Cells

- Less Flexible Design: The rigid cylindrical shape limits design flexibility in battery pack configurations.

- Potential for Higher Internal Resistance: The internal structure can lead to higher resistance and lower efficiency than other cell formats.

Part 3. Overview of LiFePO4 prismatic cells

Prismatic LiFePO4 cells are rectangular and typically enclosed in a flat, hard casing. They come in various sizes and capacities, allowing for customizable battery pack designs.

Advantages of Prismatic Cells

- Flexible Design: The rectangular shape allows more efficient use of space in battery packs, making them ideal for applications with specific form factor requirements.

- Lower Internal Resistance: The design often results in lower internal resistance, leading to higher efficiency and performance.

- High Capacity: Prismatic cells can hold more material, offering higher capacity in a single cell than cylindrical cells.

Disadvantages of Prismatic Cells

- Thermal Management Challenges: The flat design can pose challenges in heat dissipation, increasing the risk of overheating.

- Manufacturing Complexity: Prismatic cells can be more complex and expensive due to their varied sizes and shapes.

- Less Mechanical Robustness: The casing is generally less robust than cylindrical cells, making them more prone to physical damage.

Part 4. What is the difference between prismatic and cylindrical cells in LiFePO4?

1. Energy Density

When comparing energy density, cylindrical cells generally have an edge due to their compact design. However, prismatic cells can achieve similar or even higher energy densities in specific applications due to their ability to pack more material in a single cell.

2. Thermal Management

Cylindrical cells excel in thermal management due to their shape, which promotes efficient cooling. While offering advantages in space utilization, Prismatic cells can face challenges maintaining optimal temperatures, especially in high-demand applications.

3. Cycle Life

Cylindrical and prismatic LiFePO4 cells offer excellent cycle life, often exceeding 2000 charge-discharge cycles. However, due to their lower internal resistance, prismatic cells may have a slight edge in applications requiring repeated high-current charging and discharging.

4. Safety

LiFePO4 chemistry is inherently safer than other lithium-ion chemistries, but the cell design also plays a crucial role. With their robust casing, cylindrical cells offer superior protection against physical damage, while prismatic cells, despite being less mechanically robust, can be designed with advanced safety features to mitigate risks.

5. Cost Considerations

The cost of LiFePO4 cells can vary significantly based on the type and specific use case. Generally, cylindrical cells are more cost-effective due to standardized manufacturing processes and economies of scale. Prismatic cells, while potentially more expensive, offer benefits that can justify the higher cost in applications requiring specific form factors and higher capacities.

6. Environmental Impact

Both cylindrical and prismatic LiFePO4 cells have a lower environmental impact compared to other lithium-ion chemistries due to the absence of cobalt and the use of more abundant materials. However, the manufacturing process, energy efficiency, and recyclability can differ. With their standardized processes, Cylindrical cells might have a slight edge in overall environmental impact.

Part 5. Cylindrical vs prismatic LiFePO4 cells: applications and suitability

Electric Vehicles

Electric vehicles use both cell types, but the choice often depends on the design and performance requirements. People prefer cylindrical cells in applications where thermal management and mechanical stability are critical. In contrast, people favor prismatic cells for their flexible design and higher capacity.

Energy Storage Systems

Prismatic cells are often the go-to for stationary energy storage systems due to their customizable form factor and high capacity. Their ability to fit into various configurations makes them ideal for residential, commercial, and utility-scale energy storage solutions.

Consumer Electronics

Cylindrical cells dominate the consumer electronics market, especially in products like laptops, power tools, and flashlights. Their high energy density, manufacturing efficiency, and mechanical robustness make them well-suited for these applications.

Part 6. FAQs

-

Why do LiFePO4 batteries come in different shapes?

LiFePO4 batteries come in different shapes, like cylindrical and prismatic, to meet various design and performance needs. Smaller devices often use cylindrical cells due to their compact size and ease of cooling. Prismatic cells are used in larger applications because they can store more energy in a single cell and have a flat shape that efficiently uses space. -

Can cylindrical and prismatic LiFePO4 cells be used interchangeably?

Cylindrical and prismatic LiFePO4 cells are not typically interchangeable. They are designed for different applications and have other physical sizes and shapes. People use cylindrical cells where space is limited, and cooling is critical. People use prismatic cells in applications requiring high energy density and efficient use of space. Switching between these types would require redesigning the battery pack or device. -

How do cylindrical and prismatic LiFePO4 cells affect the overall battery pack design?

Cylindrical and prismatic cells impact battery pack design differently. Cylindrical cells allow for flexible design due to their small size and easy-to-cool shape, making them ideal for modular designs. Prismatic cells offer higher energy density per cell, allowing for a more compact and space-efficient design. This is essential in applications like electric vehicles where space is limited. -

Are there cost differences between cylindrical and prismatic LiFePO4 cells?

Yes, there are cost differences. Cylindrical LiFePO4 cells are generally cheaper to manufacture due to their standardized size and automated production processes. Prismatic cells, conversely, can be more expensive due to their custom sizes and the complexity of their production. However, prismatic cells might offer cost savings in applications requiring fewer cells to achieve the desired energy capacity.

Related Tags:

More Articles

High‑Capacity 3S LiPo Batteries: 5000 mAh vs. 10000 mAh

Compare 3S LiPo 5000mAh vs 10000mAh batteries by weight, power, and use. Find the best fit for your drone, RC car, or boat setup.

Top 5 Applications for Small 3S LiPo Batteries

Small 3S LiPo batteries power drones, RC gear, wearables, and robotics with high energy and low weight. Making them ideal for compact electronics projects.

Building and Charging Your Own 3S LiPo Pack: A Step‑by‑Step Guide

Learn how to build, balance, and charge a 3S LiPo battery pack safely at home with this complete DIY guide for hobbyists and beginners.

How to Choose the Right LiPo Battery Plug Type?

Discover the best LiPo battery plug types, how to choose them, and expert tips for safe usage, soldering, and maintenance.

Choosing the Right Connector for Your 3S LiPo Battery

Choosing the right 3S LiPo connector depends on current, space, and use. Learn the pros and cons of XT60, JST, EC3, and more.