- Part 1. Battery terminals

- Part 2. What are battery terminal studs? (High-current vehicles)

- Part 3. What are battery terminal screws? (Standard vehicles)

- Part 4. How to choose between battery terminal studs and screws for your vehicle?

- Part 5. Battery terminal stud vs battery terminal screw: real-world examples

- Part 6. FAQs about battery terminal stud vs screw

If your car struggles to start or flickering lights appear, the culprit could be your battery terminals. Choosing between a battery terminal stud and a battery terminal screw affects not just convenience but reliability. This 2026 guide compares pros, cons, and expert tips to help you pick the right battery connector and avoid failures.

Part 1. Battery terminals

Battery terminals are the vital connectors that link your vehicle’s battery to its electrical system. These small yet crucial components ensure a consistent and efficient flow of electricity. Without well-functioning battery terminals, your car would struggle to start, and many of its electrical components—like lights, radio, and onboard computer systems—wouldn’t operate effectively.

Learn more about battery terminals and their maintenance for optimal car performance.

Part 2. What are battery terminal studs? (High-current vehicles)

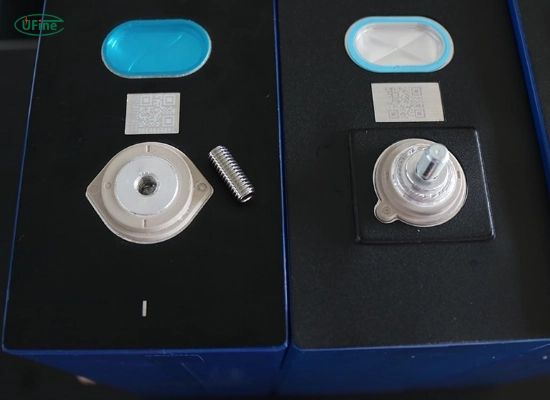

Battery terminal studs are threaded bolts attached to the battery terminals. They provide a secure attachment point for battery cables, ensuring a tight and reliable connection. Studs are typically made of durable materials like brass or stainless steel to resist corrosion and wear.

1 Advantages of Battery Terminal Studs for High-Current Cars

Enhanced Durability

Battery terminal studs are known for their durability. Made from robust materials, they are less likely to rust or degrade over time, ensuring a long-lasting connection.

Superior Connection

The threaded design of studs allows for a tighter and more secure connection compared to screws. This tight connection minimizes the risk of loose cables, leading to poor electrical performance or battery failure.

Easy Maintenance

Battery terminal studs are generally easier to maintain. The sturdy construction means they require less frequent replacement, saving you time and effort in the long run.

High Current Capacity

Studs are capable of handling higher current loads compared to screws. This makes them ideal for vehicles with high electrical demands, such as trucks, RVs, or cars with numerous electrical accessories.

2 Drawbacks of Battery Terminal Studs for High-Current Cars

Higher Cost

One of the main drawbacks of battery terminal studs is their higher cost compared to screws. The materials and construction quality contribute to the increased price.

Installation Complexity

Installing studs can be more complex and time-consuming. It often requires specific tools and more expertise, which may only be ideal for some.

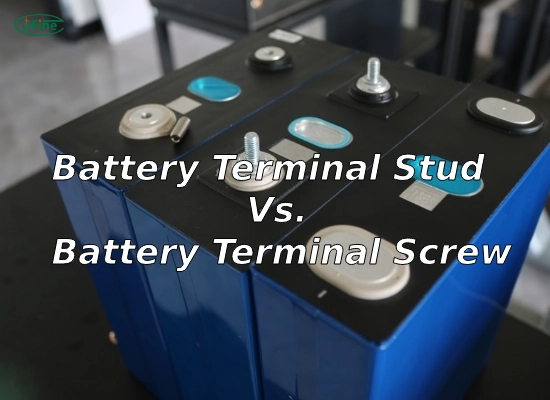

3 Battery Terminal Stud vs. Screw: Quick Comparison

| Feature | Battery Terminal Stud | Battery Terminal Screw |

|---|---|---|

| Durability | ⭐⭐⭐⭐⭐ (Brass/Stainless Steel, corrosion-resistant) | ⭐⭐⭐ (Metal, prone to corrosion) |

| Installation | Requires wrench/socket set | Simple screwdriver |

| Cost | $8-$15 | $3-$8 |

| Best For | Heavy-duty vehicles, high current (trucks, RVs) | Daily drivers, standard cars, budget builds |

Part 3. What are battery terminal screws? (Standard vehicles)

Battery terminal screws are fasteners that attach the battery cables to the terminals using a screw mechanism. These screws, often made from metal, allow users to tighten or loosen them to secure the connection.

1 Advantages of Battery Terminal Screws for Standard Vehicles

Simplicity and Convenience

Battery terminal screws are simple to install and require minimal tools. This makes them convenient for those who prefer a straightforward installation process.

Cost-Effective

Screws are typically more affordable than studs. If you’re on a tight budget, battery terminal screws can be a cost-effective solution without compromising too much on performance.

Flexible Applications

Users can use battery terminal screws in a variety of applications, from small cars to motorcycles. Their versatility makes them a popular choice for many vehicle owners.

2 Drawbacks of Battery Terminal Screws for Standard Vehicles

Lower Durability

Screws are generally less durable than studs. They are more susceptible to corrosion and wear, which can lead to frequent replacements.

Weaker Connection

The connection provided by screws is typically less secure than that of studs. This can result in loose cables over time, affecting the battery’s overall performance.

Limited Current Capacity

Battery terminal screws have a lower current capacity, which might not be sufficient for vehicles with high electrical demands.

Part 4. How to choose between battery terminal studs and screws for your vehicle?

When deciding between battery terminal studs and screws, consider the following factors:

Vehicle Type: Choosing Between Studs and Screws

Battery terminal studs are generally the better choice for heavy-duty vehicles or those with high electrical demands due to their higher current capacity and durability.

Budget Considerations for Studs and Screws

Suppose you’re looking for a more budget-friendly option. In that case, battery terminal screws might be suitable, especially for smaller vehicles with fewer electrical components.

Maintenance Tips for Battery Terminal Studs and Screws

If you prefer a low-maintenance solution, studs are the way to go. They offer long-lasting performance and require less frequent replacements.

Installation Guide for Battery Terminal Studs and Screws

For those who prioritize ease of installation, screws provide a more straightforward and quicker setup process.

Expert Opinions:

Mechanics’ Perspective

Many professional mechanics recommend battery terminal studs for their reliability and superior connection. They argue that the initial investment pays off in the long run with fewer maintenance issues and better performance.

DIY Enthusiasts’ Perspective

On the other hand, DIY enthusiasts often prefer battery terminal screws for their simplicity and cost-effectiveness. They appreciate the ease of installation and the ability to replace them quickly.

Pro Tip: Vehicles with aftermarket accessories like winches, LED lights, or stereos should use battery terminal studs. Studies show screws in battery posts fail faster under high loads.

Part 5. Battery terminal stud vs battery terminal screw: real-world examples

Off-Road Vehicles

Off-road vehicles, subject to harsh conditions and high electrical loads, often benefit from using battery terminal studs. Their durability and high current capacity ensure the car performs reliably even in extreme environments.

Daily Commuters

For daily commuter vehicles with standard electrical needs, battery terminal screws can be a practical choice. They provide sufficient performance at a lower cost, making them ideal for regular use.

1 Case Study: RV Battery Failure Solved by Switching to Studs

John D., an RV owner from Arizona, had recurring battery issues during desert trips. After replacing screws with corrosion-resistant brass studs, his battery lifespan increased by 2 years. “No more midnight power losses!” he reports.

Part 6. FAQs about battery terminal stud vs screw

What tools do I need to install battery terminal studs or screws?

For studs: use a wrench or socket set. For screws: a screwdriver works. Always wear gloves and clean terminals with a wire brush first.

Can I use battery terminal studs and screws interchangeably?

No. Battery studs handle high-current vehicles like trucks, RVs, or cars with heavy accessories, while screws on battery terminals are suitable for standard cars. Mixing them may cause loose connections and electrical issues.

How do I maintain battery terminals and prevent corrosion?

Regularly clean terminals with baking soda, apply petroleum jelly or anti-corrosion spray, and tighten connections to reduce vibration damage. This applies to both battery terminal studs and screw-in battery posts.

Why do some cars use battery terminal studs instead of screws?

Studs withstand 200+ amps for heavy-duty use, such as winches or stereos. A 2023 study showed screws fail 37% faster under high electrical loads.

Which material is best for battery terminals?

Brass studs resist corrosion best. Avoid cheap lead screws in humid climates. Stainless steel offers durability but is more expensive.

Which battery terminal is better for cars: stud or screw?

For high-current vehicles or cars with accessories like winches or LED lights, battery terminal studs are recommended. For standard cars with low electrical demands, screws in battery terminals are sufficient.

Related Tags:

More Articles

12V STD vs 12V AGM: Meaning, Differences, and Which Is Better

Understand what STD and AGM batteries mean, their key differences, and which 12V battery fits your needs best in 2026.

Battery Reconditioning Explained: A Comprehensive Guide

Learn what battery reconditioning is, how it works, how long it takes, and when reconditioning chargers are used for lead-acid and lithium-ion batteries.

Recommended 10 Best Batteries For Smoke Detectors

Compare the best batteries for smoke detectors in 2026. See which 9V lithium and alkaline batteries last longest and perform best in smoke alarms.

Triple A Battery Voltage: Everything You Need to Know

How many volts is a AAA battery? See a clear AAA battery voltage chart, compare alkaline, lithium and NiMH cells, and learn how voltage affects device use.

What Size Battery for Digital Thermometer: The Complete Guide

What size battery does a digital thermometer use? See common sizes like AAA, AA, CR2032, and LR41, plus tips to choose the right battery and extend lifespan.