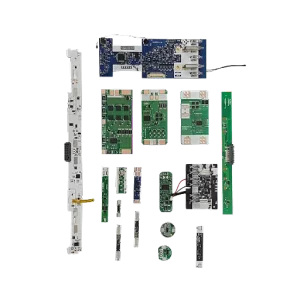

Are you curious about the protection circuit modules? In this article, we will take a deep dive into the realm of PCMs and unravel all the essential information you need to know. From understanding what exactly a protection circuit module is to discovering how it works and exploring its various components, we’ll make sure you have a solid grasp on this crucial electronic component. Let’s start!

Part 1. What is a protection circuit module?

The Protection Circuit Module is an essential electronic component designed to monitor and safeguard various devices, ranging from small consumer electronics to larger industrial equipment. Its primary function is to protect the device and its battery from potential hazards, such as overcharging, over-discharging, over current, and short circuits. By incorporating advanced circuitry and intelligent algorithms, the PCM is a reliable guardian, ensuring electronic devices’ safe and efficient operation.

Part 2. How do protection circuit modules work?

Protection Circuit Modules (PCMs) function through the integration of Printed Circuit Boards (PCBs) and Positive Temperature Coefficient (PTC) devices, employing a combination of electronic components to ensure the safety and efficiency of lithium batteries.

Printed Circuit Board (PCB):

The PCB serves as the foundation of the protection circuit module, hosting various electronic components and providing the necessary connections for their operation.

Battery Management IC (Integrated Circuit): This small chip acts as the brains of the PCM, overseeing the monitoring and control functions.

MOSFETs (Metal-Oxide-Semiconductor Field-Effect Transistors): MOSFETs serve as switches within the PCM, controlling the current flow to and from the battery.

Resistors and Capacitors: These passive components assist in regulating voltage and current, contributing to the system’s stability.

Positive Temperature Coefficient (PTC) Devices:

PTC Thermistors: PTC thermistors are temperature-sensitive resistors that exhibit a sharp increase in resistance when subjected to high temperatures. In the PCM, they are strategically placed to monitor current flow.

Overcurrent Protection: When excessive current flows through the battery, leading to potential overheating or damage, the PTC thermistors respond by increasing their resistance. This action limits the current passing through the circuit, protecting the battery from harm.

Collaborative Operation:

Monitoring and Control: The battery management IC continuously monitors parameters such as voltage, current, and temperature. The IC triggers appropriate protective measures if abnormal conditions are detected, such as overcharge, over-discharge, or short circuit.

Activation of Safety Mechanisms: In an over current situation, the PTC devices quickly respond by limiting the current flow, preventing further escalation of the issue. Meanwhile, the PCB coordinates the overall operation, ensuring timely and effective protection.

Part 3. Components of the protection circuit module

Battery Management IC (Integrated Circuit):

- The heart of the PCM is responsible for monitoring and controlling various parameters such as voltage, current, and temperature.

- Acts as the central control unit, coordinating the operation of other components within the PCM.

MOSFETs (Metal-Oxide-Semiconductor Field-Effect Transistors):

- Serve as electronic switches within the PCM, controlling the current flow to and from the battery.

- Act as gatekeepers, regulating the power delivery to ensure safe charging and discharging.

Resistors and Capacitors:

- Assist in voltage regulation and filtering within the PCM circuitry.

- Resistors help control current flow, while capacitors store and release electrical energy as needed.

Temperature Sensors:

- Monitor the temperature of the battery and the surrounding environment.

- Provide crucial feedback to the battery management IC, enabling proactive temperature management and protection.

Positive Temperature Coefficient (PTC) Devices:

- Thermally sensitive resistors exhibit a sharp increase in resistance when subjected to high temperatures.

- Act as overcurrent protection devices, limiting current flow in response to excessive heat or current.

Fuse or Polyfuse:

- Safeguards against overcurrent conditions by interrupting the circuit in the event of a short circuit or excessive current draw.

- Acts as a failsafe mechanism to prevent damage to the battery and connected devices.

Indicator LEDs (Light-Emitting Diodes):

- Provide visual feedback regarding the status of the PCM, such as charging, discharging, or fault conditions.

- Aid in troubleshooting and identifying potential issues with the battery system.

Connector Terminals:

- Some advanced protection circuit modules feature communication interfaces, such as I2C or SPI, allowing them to communicate with external devices or systems.

- This enables the PCM to provide real-time status updates and fault notifications or receive commands for specific actions.

Part 4. How does the protection circuit module for lithium batteries work?

Single-Cell Lithium Battery

- Voltage Monitoring: The PCM constantly checks the battery’s voltage to ensure it stays within safe limits.

- Overcharge Protection: It halts charging or redirects current if the battery’s voltage gets too high during charging, preventing overcharging.

- Over-Discharge Protection: If the battery voltage drops too low during discharge, the PCM cuts off power to prevent damage from over-discharging.

- Short Circuit Detection: To prevent damage, the PCM quickly interrupts current flow upon detecting a short circuit.

- Temperature Monitoring: Temperature sensors in the PCM detect high temperatures, triggering protective measures to prevent thermal runaway.

- Activation of Safety Mechanisms: It promptly engages safety measures in response to abnormal conditions to protect the battery and connected devices.

Multi-Cell Lithium Battery

- Cell Balancing: The PCM ensures each cell in the battery pack maintains the same voltage level to prevent imbalances.

- Overcharge and Over-Discharge Protection: It provides individual protection for each cell to prevent overcharging or over-discharging.

- Communication and Control: The PCM communicates with external systems to enhance monitoring and control capabilities.

- Fault Detection and Isolation: It detects and isolates faulty cells to prevent damage from spreading to the rest of the battery pack.

Part 5. FAQs

-

What is the difference between PCB and BMS?

A PCB (Printed Circuit Board) is a physical board that connects electronic components. At the same time, a BMS (Battery Management System) is a comprehensive system that manages and monitors the performance of a battery pack, including individual cells and their protection circuitry. -

What happens if PCM fails?

Suppose a PCM (Protection Circuit Module) fails. In that case, it may result in various issues such as overcharging, over-discharging, or short circuits in the battery, which can lead to reduced battery life, damage to the battery, or even safety hazards like fire or explosion. -

What causes PCM failure?

PCM failure can be caused by manufacturing defects, physical damage, overheating, exposure to moisture or contaminants, or electrical overstress from voltage spikes or surges. -

How do I know if my PCM is bad?

Signs of a bad PCM include abnormal behavior of the battery, such as sudden voltage drops, inability to hold a charge or erratic charging behavior. Visual inspection for physical damage or burn marks on the PCM can also indicate potential issues. -

How do I reset my PCM module?

To reset a PCM module, disconnect the battery from power for a few minutes and then reconnect it.

Related Tags:

More Articles

Choosing Batteries for Trolling Motors Lightweight: Charger Options

Lithium batteries are best for trolling motors as they are lightweight long long-lasting, and efficient. This guide covers selection, charging, and care tips.

Finding 11.1 V LiPo Battery Near Me: B2B Supplier Strategies

Need 11.1V LiPo batteries near you? This guide helps B2B buyers source reliable suppliers, compare specs, and ensure safe, cost-effective deals.

11.1 V LiPo Battery 5000 mAh: Specs That Matter for Industrial Use

An 11.1V 5000mAh LiPo battery offers high capacity and stable power, ideal for drones, robotics, and industrial tools requiring long runtimes.

Lightweight Battery Packs for Trolling Motors: Top Features

Looking for the best lightweight trolling motor battery? This guide covers top features, battery types, and tips to boost your boating performance.

Safe Charging Protocols for Your 11.1V LiPo Battery Charger

Safely charge your 11.1V LiPo battery by following proper rates, using safety tools, and avoiding common charging mistakes.